Get the free Crack Detection in Aluminium 2024-T3 Plates and in

Show details

Crack Detection in Aluminum 2024T3 Plates and in

an Airbus A320 Attack using Electrical Crack Gauges

Ioannis PITROPAKIS1, Hedge PFEIFFER1, Thomas GESANG2,

Stein JANSSENS3 and Martine WEVERS1

1Katholieke

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign crack detection in aluminium

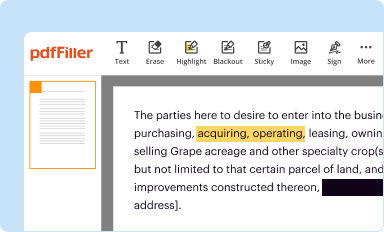

Edit your crack detection in aluminium form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

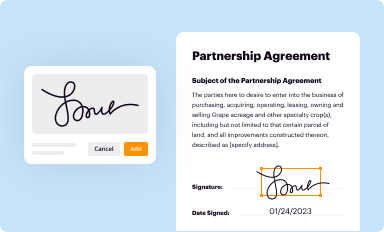

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

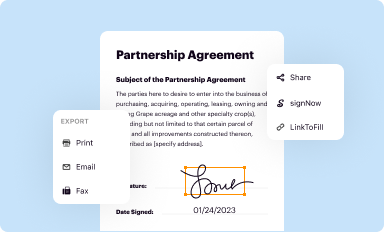

Share your form instantly

Email, fax, or share your crack detection in aluminium form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing crack detection in aluminium online

To use the services of a skilled PDF editor, follow these steps:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

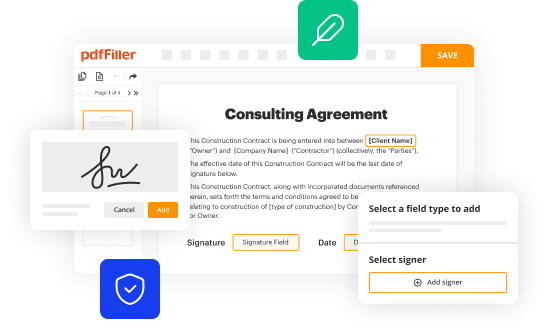

Edit crack detection in aluminium. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

With pdfFiller, dealing with documents is always straightforward.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out crack detection in aluminium

How to fill out crack detection in aluminium:

01

Prepare the aluminium surface by cleaning it thoroughly to remove any dirt, dust, or grease. Use a mild detergent and water or a suitable solvent for cleaning.

02

Inspect the aluminium surface for any visible cracks, paying attention to areas prone to stress or impact. Use a magnifying glass if needed to identify fine cracks that may not be visible to the naked eye.

03

Use a crack detection technique such as dye penetrant testing or magnetic particle inspection to identify cracks that are not visible to the naked eye. The specific technique will depend on the equipment and resources available.

04

If using dye penetrant testing, apply the penetrant to the aluminium surface and allow it to penetrate into any cracks for a specified period of time. Then, remove the excess penetrant and apply a developer to reveal any cracks.

05

If using magnetic particle inspection, apply a magnetic field to the aluminium surface and introduce iron particles or a fluorescent dye. Any cracks will disrupt the magnetic field, causing the particles or dye to accumulate at the crack site, making it visible under proper lighting.

06

Carefully inspect the aluminium surface for any indications of cracks, such as visible dyed penetrant or accumulated particles/dye. Mark the location and size of the cracks for further evaluation.

07

Evaluate the severity and extent of the detected cracks to determine the appropriate action. Minor cracks may require only repair or reinforcement, while major cracks may necessitate replacement or further investigation.

08

Document the crack detection process, including details of the inspection technique used, the location and size of detected cracks, and any recommended actions. This documentation will help track the condition of the aluminium and plan future inspections or repairs.

Who needs crack detection in aluminium:

01

Manufacturers: Companies involved in the production of aluminium components or structures need crack detection to ensure the quality and reliability of their products. Crack detection helps identify any defects or weaknesses that can compromise the integrity of the aluminium and lead to failures or accidents.

02

Maintenance and Repair Personnel: Professionals responsible for the maintenance and repair of aluminium structures, such as bridges, aircraft, or industrial equipment, need crack detection to assess the condition of the aluminium and identify any cracks or potential failure points. This allows them to take appropriate actions, such as repairs or replacements, to ensure the safety and longevity of the structures.

03

Inspection Agencies: Independent inspection agencies or quality control departments often perform crack detection in aluminium to verify the compliance of components or structures with applicable standards and regulations. This ensures that the aluminium meets the required safety and quality requirements before being used in various applications.

Overall, crack detection in aluminium is essential for ensuring the structural integrity, safety, and reliability of aluminium components or structures, and it is a crucial step in manufacturing, maintenance, and quality control processes.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my crack detection in aluminium directly from Gmail?

pdfFiller’s add-on for Gmail enables you to create, edit, fill out and eSign your crack detection in aluminium and any other documents you receive right in your inbox. Visit Google Workspace Marketplace and install pdfFiller for Gmail. Get rid of time-consuming steps and manage your documents and eSignatures effortlessly.

Can I create an electronic signature for signing my crack detection in aluminium in Gmail?

With pdfFiller's add-on, you may upload, type, or draw a signature in Gmail. You can eSign your crack detection in aluminium and other papers directly in your mailbox with pdfFiller. To preserve signed papers and your personal signatures, create an account.

How do I complete crack detection in aluminium on an iOS device?

Download and install the pdfFiller iOS app. Then, launch the app and log in or create an account to have access to all of the editing tools of the solution. Upload your crack detection in aluminium from your device or cloud storage to open it, or input the document URL. After filling out all of the essential areas in the document and eSigning it (if necessary), you may save it or share it with others.

What is crack detection in aluminium?

Crack detection in aluminium is a process of identifying and examining cracks or defects in aluminium materials.

Who is required to file crack detection in aluminium?

Manufacturers, suppliers, or users of aluminium products may be required to file crack detection reports.

How to fill out crack detection in aluminium?

Crack detection in aluminium can be filled out by conducting non-destructive testing methods like ultrasonic testing or dye penetrant inspection.

What is the purpose of crack detection in aluminium?

The purpose of crack detection in aluminium is to ensure the structural integrity and safety of aluminium components.

What information must be reported on crack detection in aluminium?

The report should include details on the location, size, and severity of cracks found, as well as recommendations for repairs or replacements.

Fill out your crack detection in aluminium online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Crack Detection In Aluminium is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.