Get the free Electric Resistance Welded (ERW) Pipes and Tubes 2016 - 2024

Show details

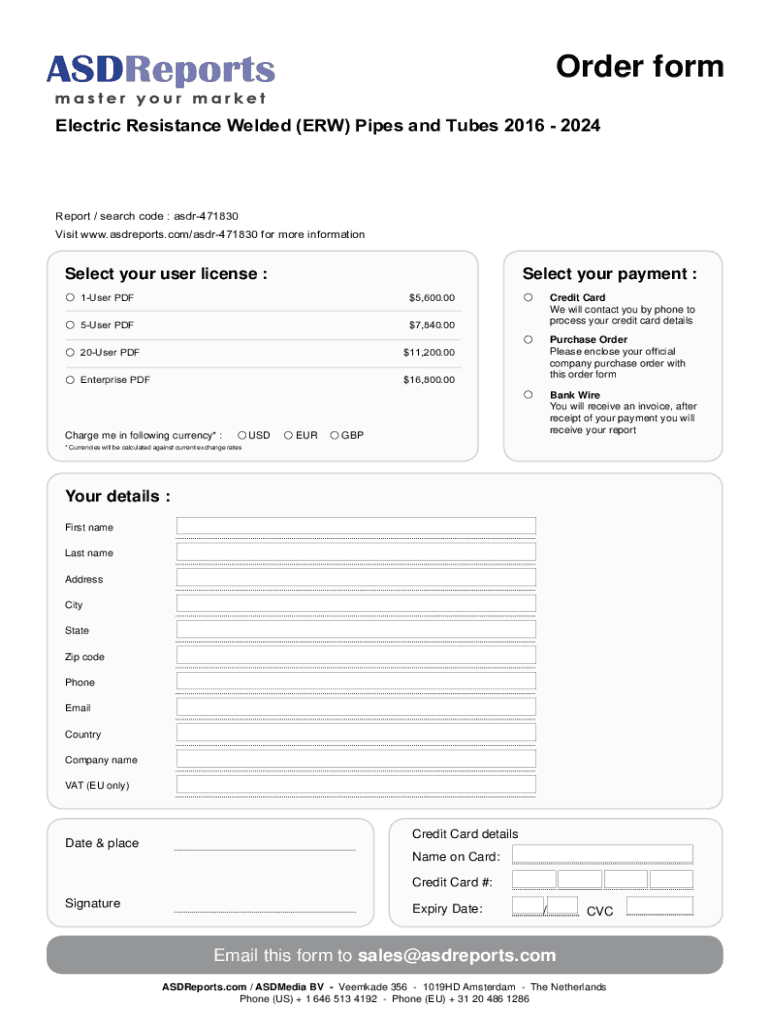

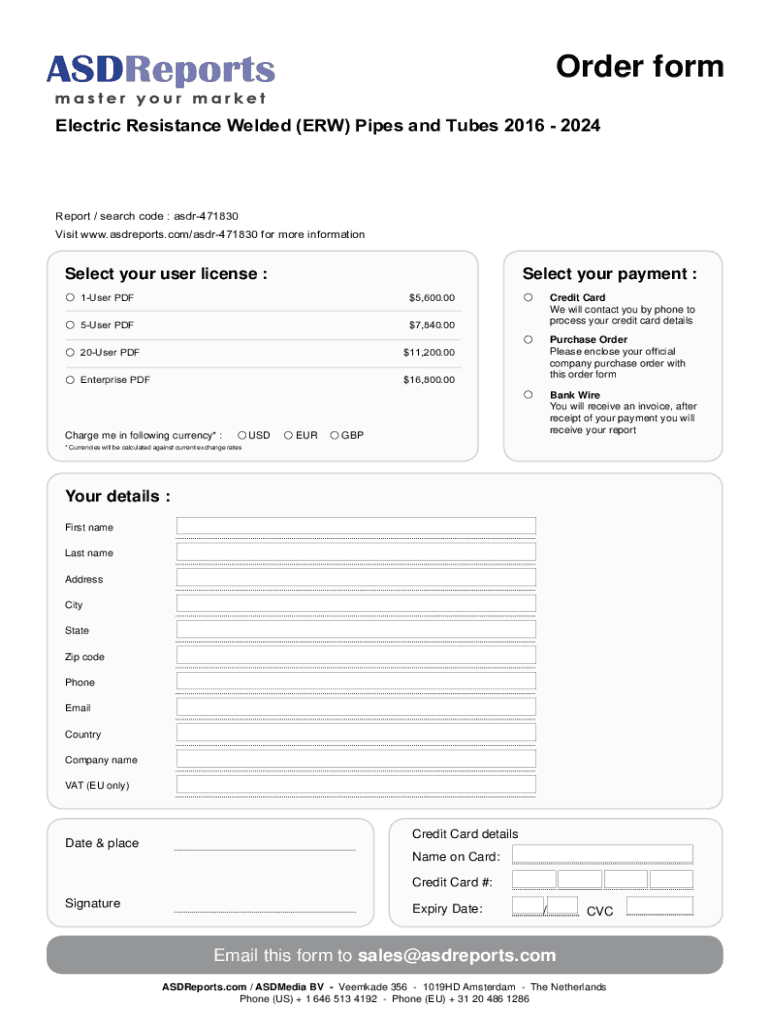

Order form Electric Resistance Welded (ERA) Pipes and Tubes 2016 2024Report / search code : asdr471830 Visit www.asdreports.com/asdr471830 for more informationSelect your user license :Select your

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign electric resistance welded erw

Edit your electric resistance welded erw form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your electric resistance welded erw form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing electric resistance welded erw online

Follow the steps down below to benefit from a competent PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit electric resistance welded erw. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

pdfFiller makes working with documents easier than you could ever imagine. Create an account to find out for yourself how it works!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out electric resistance welded erw

How to fill out electric resistance welded erw

01

Start by gathering all the necessary tools and materials, including the electric resistance welded (ERW) pipe, welding machine, safety gear (gloves, goggles, etc.), and welding electrodes suitable for ERW welding.

02

Ensure that the ERW pipe is clean and free from any contaminants or rust. Use a wire brush or sandpaper to remove any surface dirt or debris.

03

Position the ERW pipe and secure it in place using clamps or a vise, ensuring that it remains steady during the welding process.

04

Set up the welding machine according to the manufacturer's instructions, including adjusting the appropriate settings for ERW welding.

05

Put on the necessary safety gear to protect yourself from sparks and heat generated during the welding process.

06

Start the welding process by striking an arc using the welding electrode against the ERW pipe's surface. Maintain a steady and consistent welding speed.

07

Move the electrode along the joint, applying slight pressure to ensure proper fusion and penetration of the weld.

08

Continue welding along the joint until the desired length is covered, making sure to maintain the appropriate welding speed and angle.

09

Once the welding is complete, allow the welded area to cool down gradually to prevent any distortion or stress in the weld joint.

10

Inspect the welded joint for any defects, such as cracks or insufficient penetration. If necessary, perform any required repairs or reinforcement.

11

Clean the welded area to remove any welding residues or slag. Use a wire brush or appropriate cleaning method to achieve a smooth and clean finish.

12

Depending on the specific application and requirements, further finishing or coating processes may be necessary to protect the ERW welded joint from corrosion or other environmental factors.

Who needs electric resistance welded erw?

01

Electric resistance welded (ERW) pipes are commonly used in various industries and applications, including:

02

- Oil and gas transportation: ERW pipes are widely employed for the transportation of oil, gas, and other fluids due to their durability and excellent resistance to corrosion.

03

- Construction and infrastructure: ERW pipes are used in constructing buildings, bridges, and other structures due to their high strength and reliability.

04

- Automotive industry: ERW pipes find application in manufacturing automotive components, such as exhaust systems or structural parts.

05

- Plumbing and water supply: ERW pipes are used for plumbing systems and water supply networks due to their ability to withstand high pressure and corrosion resistance.

06

- Industrial and manufacturing processes: ERW pipes are utilized in various industrial processes, such as the conveyance of fluids or gases.

07

- Agricultural sector: ERW pipes are used for irrigation systems, water distribution in agriculture, and livestock management.

08

- Infrastructure development: ERW pipes are essential for the development of infrastructure projects, including pipelines, sewer systems, and utilities.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send electric resistance welded erw to be eSigned by others?

When your electric resistance welded erw is finished, send it to recipients securely and gather eSignatures with pdfFiller. You may email, text, fax, mail, or notarize a PDF straight from your account. Create an account today to test it.

How do I edit electric resistance welded erw on an iOS device?

Use the pdfFiller app for iOS to make, edit, and share electric resistance welded erw from your phone. Apple's store will have it up and running in no time. It's possible to get a free trial and choose a subscription plan that fits your needs.

How can I fill out electric resistance welded erw on an iOS device?

Install the pdfFiller app on your iOS device to fill out papers. If you have a subscription to the service, create an account or log in to an existing one. After completing the registration process, upload your electric resistance welded erw. You may now use pdfFiller's advanced features, such as adding fillable fields and eSigning documents, and accessing them from any device, wherever you are.

What is electric resistance welded erw?

Electric resistance welded (ERW) refers to a type of welding process in which metal is joined together through the application of heat and pressure.

Who is required to file electric resistance welded erw?

Any business or individual engaged in the production or distribution of electric resistance welded products may be required to file electric resistance welded erw forms.

How to fill out electric resistance welded erw?

To fill out electric resistance welded erw forms, one must collect relevant information about the production process, including materials used, production quantities, and any relevant certifications.

What is the purpose of electric resistance welded erw?

The purpose of electric resistance welded erw forms is to track the production and distribution of electric resistance welded products for regulatory and compliance purposes.

What information must be reported on electric resistance welded erw?

Information such as production quantities, materials used, production location, and any relevant certifications must be reported on electric resistance welded erw forms.

Fill out your electric resistance welded erw online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Electric Resistance Welded Erw is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.