Get the free Wood drying kiln process device description FORM AQ225

Show details

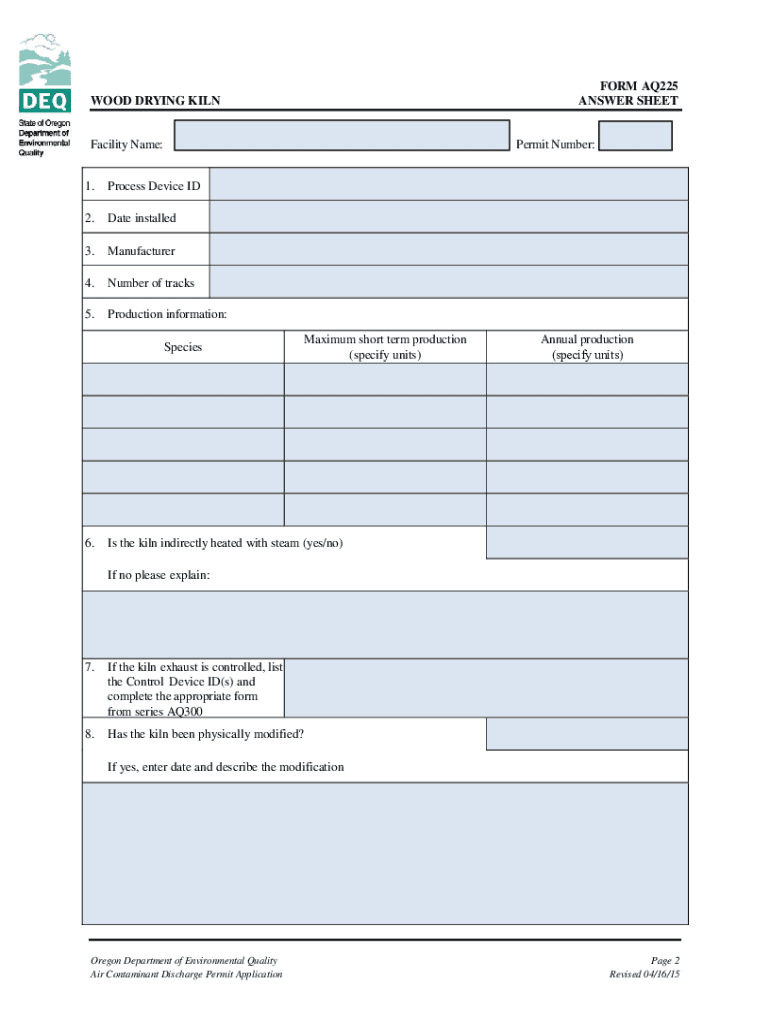

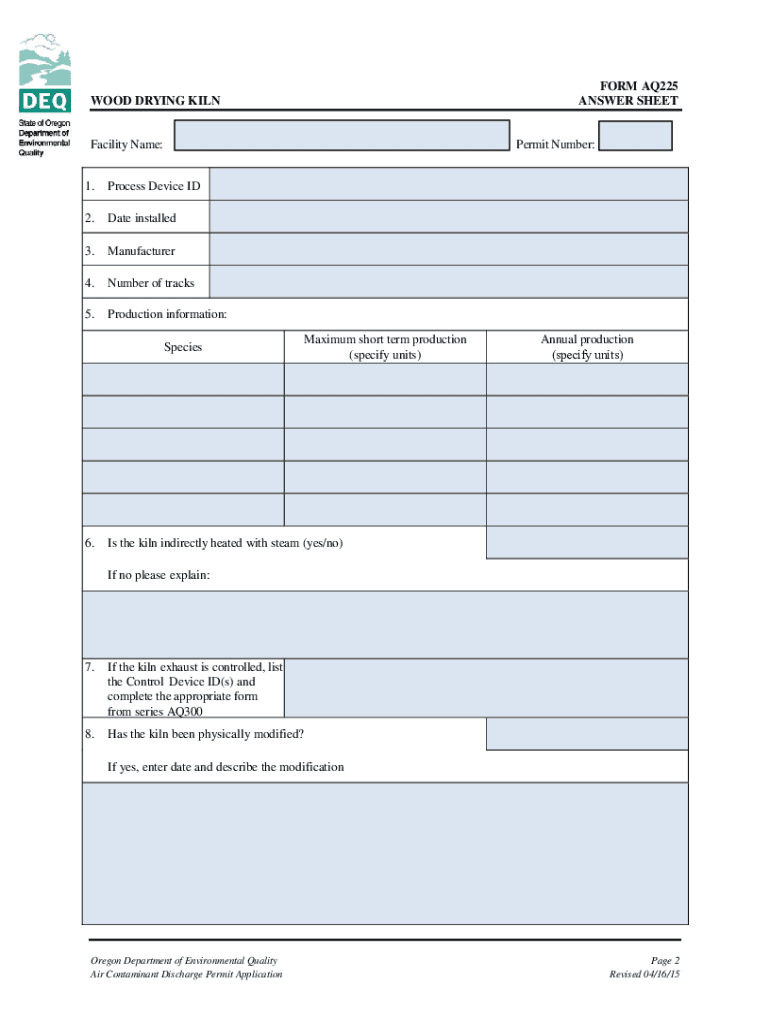

WOOD DRYING INFORM AQ225 INSTRUCTIONSComplete one Process Device Description form for each existing and/or future (if known) dry kiln. 1. Enter the process device identification label (e.g. Alpha

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign wood drying kiln process

Edit your wood drying kiln process form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your wood drying kiln process form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit wood drying kiln process online

Follow the guidelines below to benefit from the PDF editor's expertise:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit wood drying kiln process. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

With pdfFiller, it's always easy to work with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out wood drying kiln process

How to fill out wood drying kiln process

01

Start by preparing the wood to be dried. This includes cutting it into smaller pieces, removing any bark or debris, and properly stacking it.

02

Place the prepared wood inside the wood drying kiln. Make sure to leave enough space between the pieces for proper air circulation.

03

Close the kiln door tightly to create a sealed environment. This will prevent any moisture from entering or escaping.

04

Set the temperature and humidity levels according to the specific requirements of the wood species you are drying. Different types of wood may have different drying needs.

05

Monitor the temperature and humidity levels regularly during the drying process. Make necessary adjustments if needed.

06

Allow the wood to dry for the recommended duration. This time can vary depending on the thickness and moisture content of the wood.

07

Once the drying process is complete, open the kiln door carefully and remove the dried wood.

08

Inspect the wood for any signs of damage or defect. If necessary, perform additional treatments or finishing processes before using or selling the dried wood.

Who needs wood drying kiln process?

01

Wood drying kiln process is needed by various industries and individuals involved in woodworking and timber-related activities.

02

Furniture manufacturers require properly dried wood to ensure the stability and durability of their products.

03

Construction companies need dry wood to prevent warping, shrinking or cracking of wooden structures.

04

Flooring manufacturers rely on wood drying kilns to produce high-quality and stable wooden flooring materials.

05

Musical instrument makers, such as guitar manufacturers, need properly dried wood to achieve optimal sound quality.

06

Woodworkers and artisans who create custom wooden products also utilize wood drying kilns to prepare their materials.

07

In summary, anyone working with wood and requiring dry, stable, and usable wood can benefit from the wood drying kiln process.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my wood drying kiln process directly from Gmail?

It's easy to use pdfFiller's Gmail add-on to make and edit your wood drying kiln process and any other documents you get right in your email. You can also eSign them. Take a look at the Google Workspace Marketplace and get pdfFiller for Gmail. Get rid of the time-consuming steps and easily manage your documents and eSignatures with the help of an app.

How do I make edits in wood drying kiln process without leaving Chrome?

Install the pdfFiller Google Chrome Extension to edit wood drying kiln process and other documents straight from Google search results. When reading documents in Chrome, you may edit them. Create fillable PDFs and update existing PDFs using pdfFiller.

How do I complete wood drying kiln process on an iOS device?

Install the pdfFiller app on your iOS device to fill out papers. If you have a subscription to the service, create an account or log in to an existing one. After completing the registration process, upload your wood drying kiln process. You may now use pdfFiller's advanced features, such as adding fillable fields and eSigning documents, and accessing them from any device, wherever you are.

What is wood drying kiln process?

The wood drying kiln process is a method used to remove moisture from wood in order to improve its strength, durability, and stability.

Who is required to file wood drying kiln process?

Wood processing facilities and lumber manufacturers are typically required to file wood drying kiln process.

How to fill out wood drying kiln process?

The wood drying kiln process is usually filled out by documenting the type of wood, moisture content, drying temperature, and drying time.

What is the purpose of wood drying kiln process?

The purpose of wood drying kiln process is to prevent wood from warping, cracking, or shrinking, and to make it suitable for various applications.

What information must be reported on wood drying kiln process?

The information that must be reported on wood drying kiln process includes the type of wood, initial moisture content, final moisture content, drying temperature, and drying time.

Fill out your wood drying kiln process online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Wood Drying Kiln Process is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.