Get the free Self-Inspection Checklist Welding Cutting and Brazing

Show details

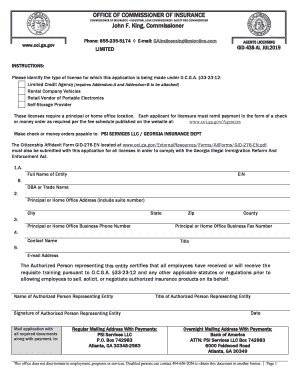

SelfInspection Checklist Welding, Cutting, and Brazing Date Inspected Date Completed Checklist Needs to be Addressed Completed Not Applicable Are only authorized and trained personnel permitted to

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign self-inspection checklist welding cutting

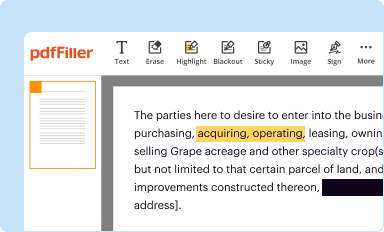

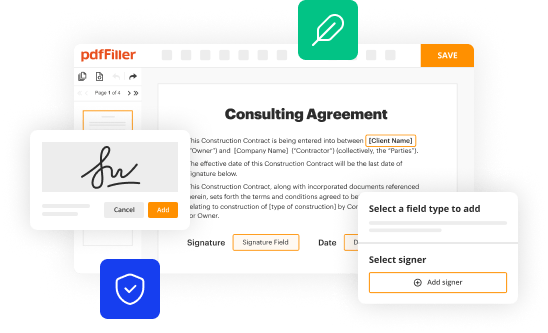

Edit your self-inspection checklist welding cutting form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

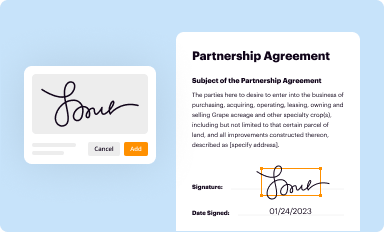

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

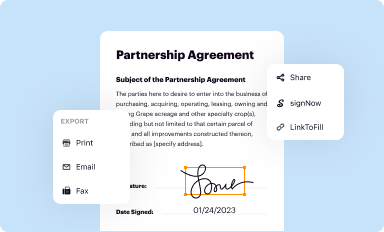

Share your form instantly

Email, fax, or share your self-inspection checklist welding cutting form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit self-inspection checklist welding cutting online

Use the instructions below to start using our professional PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit self-inspection checklist welding cutting. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

With pdfFiller, it's always easy to deal with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out self-inspection checklist welding cutting

How to fill out a self-inspection checklist for welding cutting:

01

Start by gathering the necessary information and documents related to the welding cutting process. This may include manuals, guidelines, safety procedures, and any specific requirements for your industry or company.

02

Familiarize yourself with the checklist and understand each item listed. This may involve reading through the checklist and referring to the relevant sources of information to ensure a comprehensive understanding.

03

Begin by conducting a thorough inspection of all welding and cutting equipment. Check for any signs of damage, wear and tear, or malfunctions. Ensure that all safety features are in place and working properly.

04

Assess the environment where welding cutting takes place. Look for potential hazards such as flammable materials, insufficient ventilation, or inadequate lighting. Ensure that fire prevention measures are in place, and all necessary personal protective equipment (PPE) is available.

05

Review the checklist items related to proper storage and handling of hazardous materials used in welding cutting. Confirm that all containers are labeled correctly and that proper storage protocols are followed. Check for any leaks or potential exposure hazards.

06

Scrutinize the welding and cutting processes themselves. Verify that all procedures are being followed correctly, including pre-checks, precautions, and safety measures. Pay attention to the appropriate use of protective equipment and the overall cleanliness of the work area.

07

Record your findings and observations on the checklist. Be detailed and specific, noting any areas of non-compliance or potential improvements. If any corrective actions are needed, clearly indicate them and assign responsibility for their completion.

08

Once the self-inspection is complete, review the checklist and ensure that all necessary areas have been addressed. Make sure that the inspection is thorough and accurate, as it serves as a tool to identify potential risks and ensure compliance with regulations.

09

Keep a copy of the completed self-inspection checklist for your records. File it in a designated location where it can be easily accessed and referenced for future audits or inspections.

Who needs a self-inspection checklist for welding cutting?

01

Welders and cutting operators: Welders and cutting operators who perform welding and cutting activities must use a self-inspection checklist to ensure compliance with safety standards and procedures. This helps them identify potential risks and hazards, maintain equipment and tools, and prevent accidents or injuries.

02

Safety officers and supervisors: Safety officers and supervisors are responsible for overseeing welding and cutting operations. They should use the self-inspection checklist to regularly assess and monitor compliance with safety protocols, identify areas for improvement, and take appropriate actions to mitigate risks.

03

Inspectors and auditors: Inspectors and auditors, both internal and external to the organization, may use the self-inspection checklist as a reference tool to assess the organization's compliance with safety regulations and standards related to welding cutting. It helps them identify any non-compliance issues, gaps, or deficiencies that need to be addressed.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my self-inspection checklist welding cutting in Gmail?

You can use pdfFiller’s add-on for Gmail in order to modify, fill out, and eSign your self-inspection checklist welding cutting along with other documents right in your inbox. Find pdfFiller for Gmail in Google Workspace Marketplace. Use time you spend on handling your documents and eSignatures for more important things.

How can I modify self-inspection checklist welding cutting without leaving Google Drive?

By integrating pdfFiller with Google Docs, you can streamline your document workflows and produce fillable forms that can be stored directly in Google Drive. Using the connection, you will be able to create, change, and eSign documents, including self-inspection checklist welding cutting, all without having to leave Google Drive. Add pdfFiller's features to Google Drive and you'll be able to handle your documents more effectively from any device with an internet connection.

How do I execute self-inspection checklist welding cutting online?

pdfFiller has made filling out and eSigning self-inspection checklist welding cutting easy. The solution is equipped with a set of features that enable you to edit and rearrange PDF content, add fillable fields, and eSign the document. Start a free trial to explore all the capabilities of pdfFiller, the ultimate document editing solution.

Fill out your self-inspection checklist welding cutting online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Self-Inspection Checklist Welding Cutting is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.