Get the free 1 laser surface alloying of pure aluminum with iron and ... - eprints utm

Show details

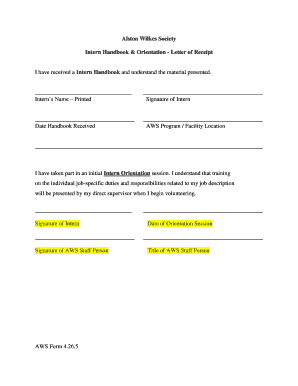

1LASER SURFACE ALLOYING OF PURE ALUMINUM WITH IRON AND NICKEL VIA LOW POWER CO2 LATERAL ADEEL SALIMUNIVERSITI TECHNOLOGY MALAYSIA2 PS2 19:16 (Find. 1/07)UNIVERSITY TECHNOLOGY MALAYSIA DECLARATION

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign 1 laser surface alloying

Edit your 1 laser surface alloying form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your 1 laser surface alloying form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit 1 laser surface alloying online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit 1 laser surface alloying. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

It's easier to work with documents with pdfFiller than you could have ever thought. You can sign up for an account to see for yourself.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out 1 laser surface alloying

How to fill out 1 laser surface alloying

01

Clean the surface of the workpiece to be alloyed using a degreaser or solvent.

02

Mount the workpiece securely on the laser surface alloying machine.

03

Adjust the laser parameters such as power, speed, and focal length according to the desired alloying results.

04

Start the laser beam and move it over the surface of the workpiece in a controlled manner to allow alloying to occur.

05

Monitor the alloying process to ensure uniform coverage and desired alloying depth.

06

Cool the alloyed surface slowly to prevent cracking or distortion.

07

Inspect the finished alloyed surface for quality and integrity.

Who needs 1 laser surface alloying?

01

Manufacturers looking to improve the hardness, wear resistance, corrosion resistance, or other surface properties of metal parts.

02

Researchers studying the effects of alloying on material properties.

03

Engineers seeking to extend the lifespan of components in harsh environments.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send 1 laser surface alloying for eSignature?

When your 1 laser surface alloying is finished, send it to recipients securely and gather eSignatures with pdfFiller. You may email, text, fax, mail, or notarize a PDF straight from your account. Create an account today to test it.

How do I make changes in 1 laser surface alloying?

The editing procedure is simple with pdfFiller. Open your 1 laser surface alloying in the editor. You may also add photos, draw arrows and lines, insert sticky notes and text boxes, and more.

Can I edit 1 laser surface alloying on an Android device?

You can make any changes to PDF files, like 1 laser surface alloying, with the help of the pdfFiller Android app. Edit, sign, and send documents right from your phone or tablet. You can use the app to make document management easier wherever you are.

What is 1 laser surface alloying?

1 laser surface alloying is a process in which a laser beam is used to melt and fuse a surface coating onto a metal substrate to improve its properties.

Who is required to file 1 laser surface alloying?

Manufacturers and companies utilizing laser surface alloying technology are required to file 1 laser surface alloying.

How to fill out 1 laser surface alloying?

To fill out 1 laser surface alloying, companies must provide detailed information about the alloying process, materials used, equipment specifications, and safety measures implemented.

What is the purpose of 1 laser surface alloying?

The purpose of 1 laser surface alloying is to enhance the surface properties of metal parts, such as wear resistance, hardness, and corrosion resistance.

What information must be reported on 1 laser surface alloying?

Information such as the type of laser used, alloying materials, processing parameters, and any environmental or safety considerations must be reported on 1 laser surface alloying.

Fill out your 1 laser surface alloying online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

1 Laser Surface Alloying is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.