Get the free Atomization and Spray Drying: - CfPA

Show details

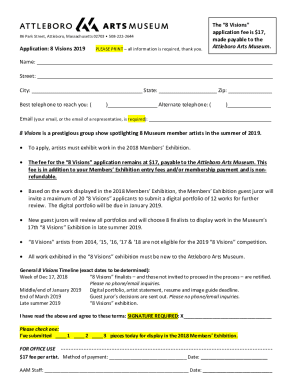

3 Ways To Register Registration Form Course Offering # 1510-204 Atomization and Spray Drying: Applied and Practical Approach October 8 9, 2015 New Brunswick, NJ Priority Code: (Please use this code

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign atomization and spray drying

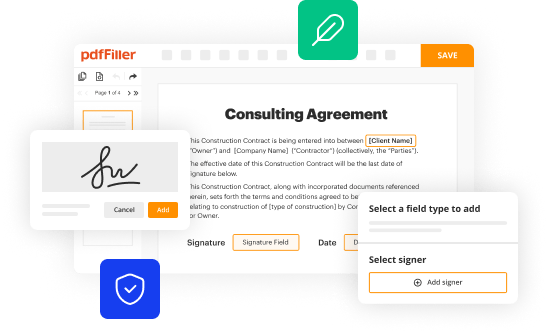

Edit your atomization and spray drying form online

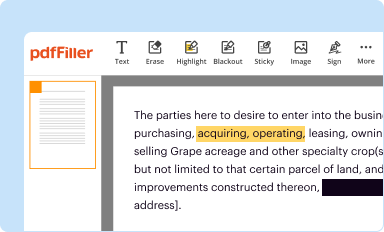

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

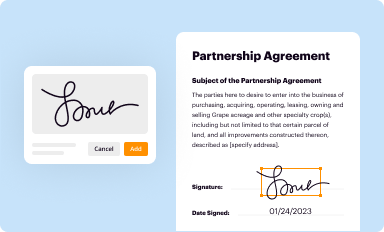

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

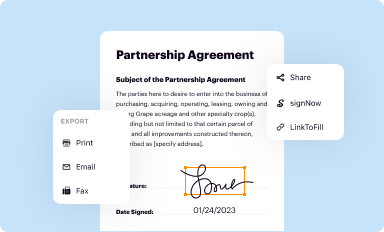

Share your form instantly

Email, fax, or share your atomization and spray drying form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit atomization and spray drying online

To use our professional PDF editor, follow these steps:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit atomization and spray drying. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out atomization and spray drying

Question:

Write point by point how to fill out atomization and spray drying. Who needs atomization and spray drying?

How to fill out atomization and spray drying:

01

Begin by understanding the purpose of atomization and spray drying. Atomization is a process that involves breaking down a liquid into fine droplets, while spray drying is a technique used to convert a liquid into a dried powder form.

02

Determine the type of material that needs to be atomized or spray dried. Different substances require different methods and equipment for the process. For example, food products may require different considerations compared to pharmaceuticals or chemicals.

03

Choose the appropriate atomization or spray drying equipment based on the material characteristics and desired outcome. This can include factors such as the type of atomizer or spray dryer, nozzle size, air pressure, temperature, and residence time.

04

Prepare the liquid material to be atomized or spray dried. This may involve pre-processing steps such as filtration, homogenization, or adjusting the concentration of the liquid. It is crucial to ensure the material is suitable for atomization or spray drying.

05

Set up the atomizer or spray dryer equipment according to the manufacturer's instructions. This includes assembling the equipment, adjusting settings such as spray pattern, droplet size, and air flow rates, and ensuring proper safety measures are in place.

06

Start the atomization or spray drying process. Monitor the process parameters closely to ensure optimal performance and desired results. This may involve adjusting variables such as liquid flow rate, atomizer speed, air pressure, and inlet/outlet temperatures.

07

Collect and handle the atomized droplets or spray dried powder appropriately. Depending on the application, this can involve post-processing steps such as particle size classification, packaging, storage, or further treatment.

08

Clean and maintain the atomization or spray drying equipment regularly to ensure its proper functioning and longevity. Follow the manufacturer's guidelines for maintenance, cleaning solutions, and troubleshooting.

09

Continuously evaluate and optimize the atomization or spray drying process for efficiency, quality, and cost-effectiveness. This can involve conducting experiments, analyzing data, and making adjustments to the process parameters if needed.

Who needs atomization and spray drying:

01

Industries that produce powdered products: Atomization and spray drying are commonly used in industries such as food, pharmaceuticals, chemicals, and cosmetics. These industries often require converting liquids into powders for various reasons, such as enhancing stability, improving solubility, or facilitating easy handling and storage.

02

Research and development: Atomization and spray drying are also utilized in research and development settings to study and understand the properties of different materials in powder form. This allows researchers to investigate new applications, test formulations, and evaluate product performance.

03

Manufacturers of controlled-release products: Atomization and spray drying can be crucial in the production of controlled-release products, where the release of certain substances needs to be controlled over time. By converting active ingredients into powders, manufacturers can achieve the desired release profiles and enhance the bioavailability of the product.

04

Industries focusing on encapsulation: Atomization and spray drying techniques are often employed in the encapsulation of active ingredients or flavors. Encapsulation helps protect the substances from degradation, control their release, and improve their stability and effectiveness.

In summary, atomization and spray drying play a vital role in converting liquid materials into powders, offering various benefits across industries such as improved stability, enhanced solubility, and easy handling. The process involves understanding the material and its requirements, selecting appropriate equipment, setting up and monitoring the process parameters, and handling the resulting products effectively.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is atomization and spray drying?

Atomization is the process of breaking down liquid into small droplets, while spray drying is a method of producing dry powder from liquid by spraying it into a hot gas stream.

Who is required to file atomization and spray drying?

Companies or industries that use atomization and spray drying processes are required to file the necessary documentation.

How to fill out atomization and spray drying?

The forms for atomization and spray drying can usually be obtained from the relevant regulatory body and must be completed accurately.

What is the purpose of atomization and spray drying?

The purpose of atomization and spray drying is to convert liquid substances into dry powder form for easier storage, transportation, and use.

What information must be reported on atomization and spray drying?

Information such as the type of liquid being atomized or spray dried, the equipment used, the process parameters, and any safety measures in place must be reported.

How can I manage my atomization and spray drying directly from Gmail?

You can use pdfFiller’s add-on for Gmail in order to modify, fill out, and eSign your atomization and spray drying along with other documents right in your inbox. Find pdfFiller for Gmail in Google Workspace Marketplace. Use time you spend on handling your documents and eSignatures for more important things.

Can I create an electronic signature for the atomization and spray drying in Chrome?

Yes. By adding the solution to your Chrome browser, you may use pdfFiller to eSign documents while also enjoying all of the PDF editor's capabilities in one spot. Create a legally enforceable eSignature by sketching, typing, or uploading a photo of your handwritten signature using the extension. Whatever option you select, you'll be able to eSign your atomization and spray drying in seconds.

How can I edit atomization and spray drying on a smartphone?

The easiest way to edit documents on a mobile device is using pdfFiller’s mobile-native apps for iOS and Android. You can download those from the Apple Store and Google Play, respectively. You can learn more about the apps here. Install and log in to the application to start editing atomization and spray drying.

Fill out your atomization and spray drying online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Atomization And Spray Drying is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.