Get the free CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AF...

Show details

This document presents a detailed study on the electrical activation and dopant diffusion behavior of ultra-shallow boron and BF2 implanted p-type silicon wafers using different annealing methods,

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign characterization of ultra-shallow implanted

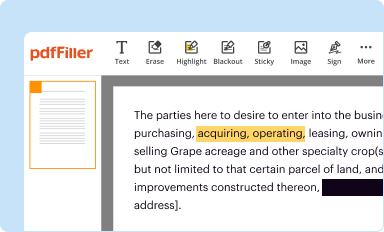

Edit your characterization of ultra-shallow implanted form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

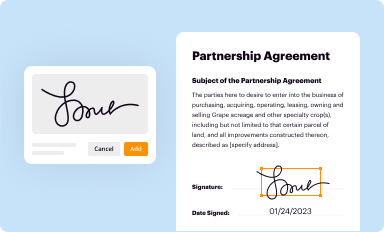

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

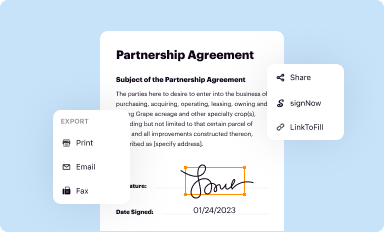

Share your form instantly

Email, fax, or share your characterization of ultra-shallow implanted form via URL. You can also download, print, or export forms to your preferred cloud storage service.

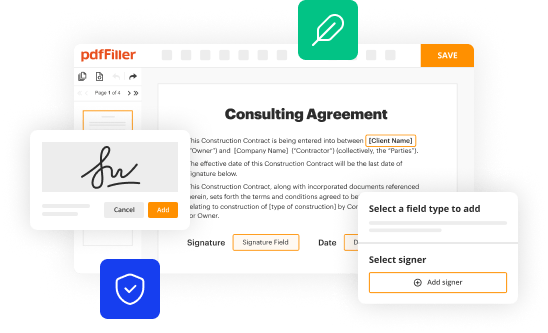

Editing characterization of ultra-shallow implanted online

In order to make advantage of the professional PDF editor, follow these steps below:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit characterization of ultra-shallow implanted. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Try it for yourself by creating an account!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out characterization of ultra-shallow implanted

How to fill out CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AFTER FLASH ANNEAL AND CONVENTIONAL RAPID THERMAL ANNEAL

01

Prepare the p-type silicon substrates by cleaning and ensuring they are free from contaminants.

02

Implant the P+ layer into the silicon substrates using an ion implanter at the desired dosage and energy.

03

Conduct a flash anneal process to activate the implanted ions and repair damage caused by implantation. This involves heating the substrate rapidly to a high temperature for a very short period.

04

Follow the flash anneal with a conventional rapid thermal anneal to ensure further activation and diffusion of the P+ layer into the silicon substrate.

05

Characterize the implanted P+ layer using various techniques, such as secondary ion mass spectrometry (SIMS) or sheet resistance measurements, to assess the depth profile and electrical properties.

06

Analyze the data to determine the uniformity and effectiveness of the implanted layer.

Who needs CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AFTER FLASH ANNEAL AND CONVENTIONAL RAPID THERMAL ANNEAL?

01

Researchers and scientists in semiconductor fabrication who require insights into ultra-shallow junctions.

02

Engineers and technologists working on advanced CMOS devices.

03

Manufacturers of silicon-based electronic devices needing quality assurance and performance evaluation of implanted layers.

04

Academic institutions conducting studies on ion implantation and annealing effects on silicon substrates.

Fill

form

: Try Risk Free

People Also Ask about

What is the difference between rapid thermal annealing and normal annealing?

The most important difference between conventional batch thermal annealing and Rapid Thermal Annealing is the fact that in an RTA system the processed wafer is never in thermal equilibrium with the surrounding environment. involving the quantum and solid state physics, optics, and engineering.

What is rapid thermal annealing?

In the semiconductor industry, rapid thermal annealing (RTA) is a semiconductor process step used for the activation of dopants and the interfacial reaction of metal contacts. In principle, the operation involves rapid heating of a wafer from ambient to approximately 1000–1500 K.

At what temperature does Lpcvd silicon nitride deposit?

Current production technologies for silicon nitride use low pressure chemical vapor deposition (LPCVD) at temperatures > 700 'C or plasma enhanced chemical vapor deposition (PECVD) at temperatures below 450 'C.

What temperature is silicon nitride annealing?

Annealing for one minute or two at 500 "C was sufficient to allow a source to operate. If the nitride layer remained structurally perfect and intact on the surface, heating for long times up to 1200 "C caused no dislocations to be introduced into the silicon.

What is P-type silicon substrate?

What is a P-type Substrate? A p-type substrate is a silicon wafer doped with trivalent impurities—most commonly boron—which introduces holes (positive charge carriers) as the majority carriers in the crystal lattice.

What are the effects of rapid thermal annealing on Lpcvd silicon nitride?

The effects of rapid thermal anneal (RTA) on film thickness, refractive index and residual stress of low pressure chemical vapor deposited (LPCVD) silicon nitride films are experimentally investigated. With the increase of RTA time, film thickness decreases in an exponential way and refractive index increases.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AFTER FLASH ANNEAL AND CONVENTIONAL RAPID THERMAL ANNEAL?

The characterization of ultra-shallow implanted P+ layer on p-type silicon substrates refers to the analysis and evaluation of the electrical and structural properties of a very thin layer of p-type doped silicon after it has undergone flash annealing and conventional rapid thermal annealing processes. This process aims to achieve improved activation of dopants and to assess the material's quality and performance for semiconductor applications.

Who is required to file CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AFTER FLASH ANNEAL AND CONVENTIONAL RAPID THERMAL ANNEAL?

Researchers and engineers involved in semiconductor manufacturing and characterization are typically required to file this type of documentation. This can include academic researchers, process engineers, and quality assurance professionals working in semiconductor fabrication facilities.

How to fill out CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AFTER FLASH ANNEAL AND CONVENTIONAL RAPID THERMAL ANNEAL?

To fill out the characterization, one must gather relevant data from experiments including dopant concentration, depth profiles, electrical measurements, and annealing parameters. This data should be organized into sections detailing the methodology, results, interpretation of findings, and any conclusions drawn from the characterization.

What is the purpose of CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AFTER FLASH ANNEAL AND CONVENTIONAL RAPID THERMAL ANNEAL?

The purpose of this characterization is to understand the effects of different annealing techniques on the electrical properties, structural integrity, and depth distribution of the implanted P+ layer in silicon. It helps in optimizing fabrication processes and improving the performance of semiconductor devices.

What information must be reported on CHARACTERIZATION OF ULTRA-SHALLOW IMPLANTED P+ LAYER ON P-TYPE SILICON SUBSTRATES AFTER FLASH ANNEAL AND CONVENTIONAL RAPID THERMAL ANNEAL?

The report must include information such as the parameters of the implantation process, details of the annealing methods used, measurements of electrical properties (like sheet resistance, mobility, carrier concentration), structural analysis results (such as SIMS profiles and XRD data), and comparisons between flash and rapid thermal annealing outcomes.

Fill out your characterization of ultra-shallow implanted online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Characterization Of Ultra-Shallow Implanted is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.