Get the free Anodizing vs. Powder Coating: How to Choose the Right ...

Show details

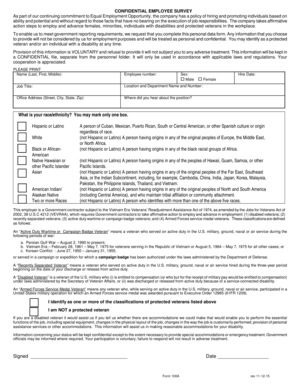

Ark wall Order Form Company Name: ___Date: ___Job Reference: ___ Pickup when ready Finish:Mill FinishContact Name: ___ Contact Number: ___Delivery Address: ___ Please Select Powder Coat: ___Natural

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign anodizing vs powder coating

Edit your anodizing vs powder coating form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your anodizing vs powder coating form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing anodizing vs powder coating online

In order to make advantage of the professional PDF editor, follow these steps below:

1

Log into your account. In case you're new, it's time to start your free trial.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit anodizing vs powder coating. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

It's easier to work with documents with pdfFiller than you can have ever thought. You may try it out for yourself by signing up for an account.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out anodizing vs powder coating

How to fill out anodizing vs powder coating

01

First, gather all the necessary materials such as anodizing solution, aluminum parts, anodizing tank, power supply, and cleaning agents.

02

Clean the aluminum parts thoroughly to remove any dirt, grease, or oxides using a suitable cleaning agent.

03

Prepare the anodizing tank by filling it with the anodizing solution and ensuring it is at the correct temperature.

04

Attach the aluminum parts to the power supply and immerse them into the anodizing solution.

05

Apply the appropriate voltage and current to the power supply to initiate the anodizing process.

06

Monitor the process closely and adjust the voltage and current as necessary to achieve the desired anodized coating thickness.

07

Once the desired coating thickness is achieved, remove the aluminum parts from the anodizing tank and rinse them in clean water.

08

Allow the parts to air dry or use compressed air to speed up the drying process.

09

Inspect the anodized coating for any defects or imperfections and make necessary touch-ups if required.

Who needs anodizing vs powder coating?

01

Industries or individuals looking for enhanced corrosion resistance on their metal products usually opt for anodizing.

02

Powder coating is preferred by industries or individuals seeking a durable and attractive finish on their metal products.

03

Anodizing is commonly used in applications where aluminum parts will be exposed to harsh environments or undergo frequent use.

04

Powder coating is suitable for a wide range of applications including automotive, architectural, and outdoor furniture industries.

05

Individuals who want to add color options to their metal products may choose anodizing or powder coating depending on their specific requirements.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit anodizing vs powder coating online?

The editing procedure is simple with pdfFiller. Open your anodizing vs powder coating in the editor. You may also add photos, draw arrows and lines, insert sticky notes and text boxes, and more.

How do I make edits in anodizing vs powder coating without leaving Chrome?

Get and add pdfFiller Google Chrome Extension to your browser to edit, fill out and eSign your anodizing vs powder coating, which you can open in the editor directly from a Google search page in just one click. Execute your fillable documents from any internet-connected device without leaving Chrome.

How do I complete anodizing vs powder coating on an Android device?

Use the pdfFiller Android app to finish your anodizing vs powder coating and other documents on your Android phone. The app has all the features you need to manage your documents, like editing content, eSigning, annotating, sharing files, and more. At any time, as long as there is an internet connection.

What is anodizing vs powder coating?

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant anodic oxide finish. Powder coating, on the other hand, is a dry finishing process where powder particles are electrostatically applied to a surface and then cured under heat to form a hard protective layer.

Who is required to file anodizing vs powder coating?

Manufacturers and businesses that perform anodizing or powder coating on metal products are typically required to file any necessary documentation or reports with regulatory agencies, particularly if the processes are part of a larger manufacturing operation.

How to fill out anodizing vs powder coating?

Filling out documentation for anodizing vs powder coating usually involves providing details about the materials used, the processes followed, compliance with safety and environmental regulations, and any quality control measures in place. Specific forms or templates will vary by regulatory body.

What is the purpose of anodizing vs powder coating?

The purpose of anodizing is to enhance corrosion resistance and surface durability, while powder coating aims to provide a protective and aesthetically pleasing finish with increased scratch and chemical resistance.

What information must be reported on anodizing vs powder coating?

Information required in reports on anodizing vs powder coating may include the types of materials processed, the coatings applied, the amounts used, safety data sheets (SDS), waste disposal methods, and any environmental impact assessments.

Fill out your anodizing vs powder coating online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Anodizing Vs Powder Coating is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.