Get the free Filling the Gap-Pressure Welding Training Program

Show details

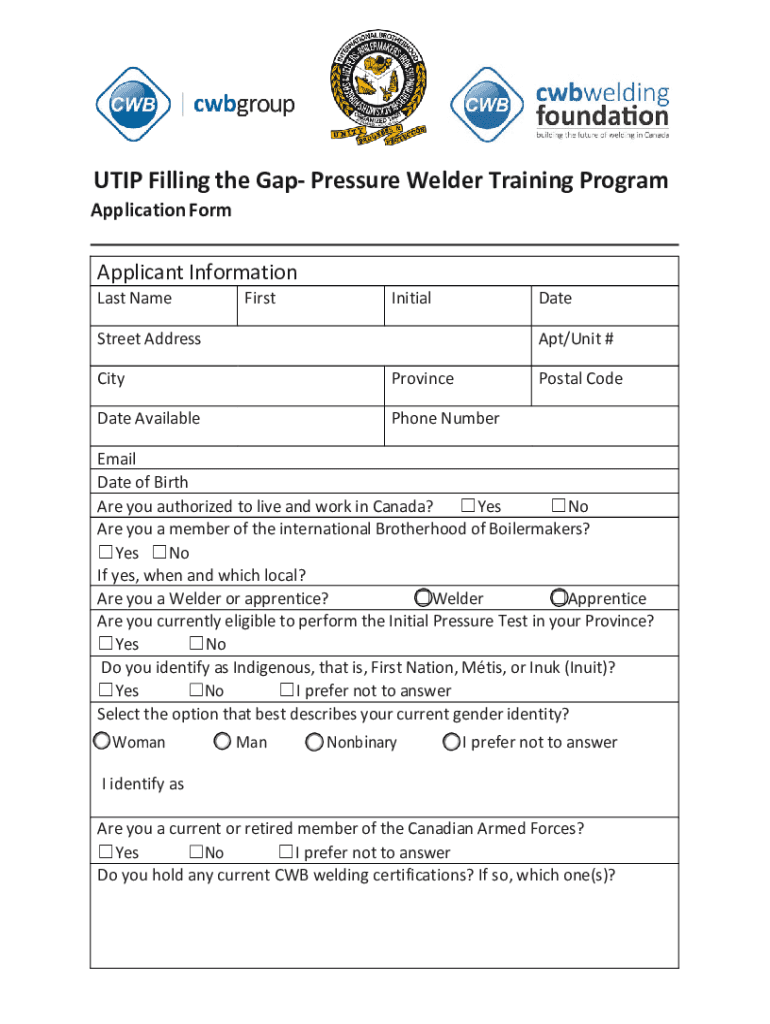

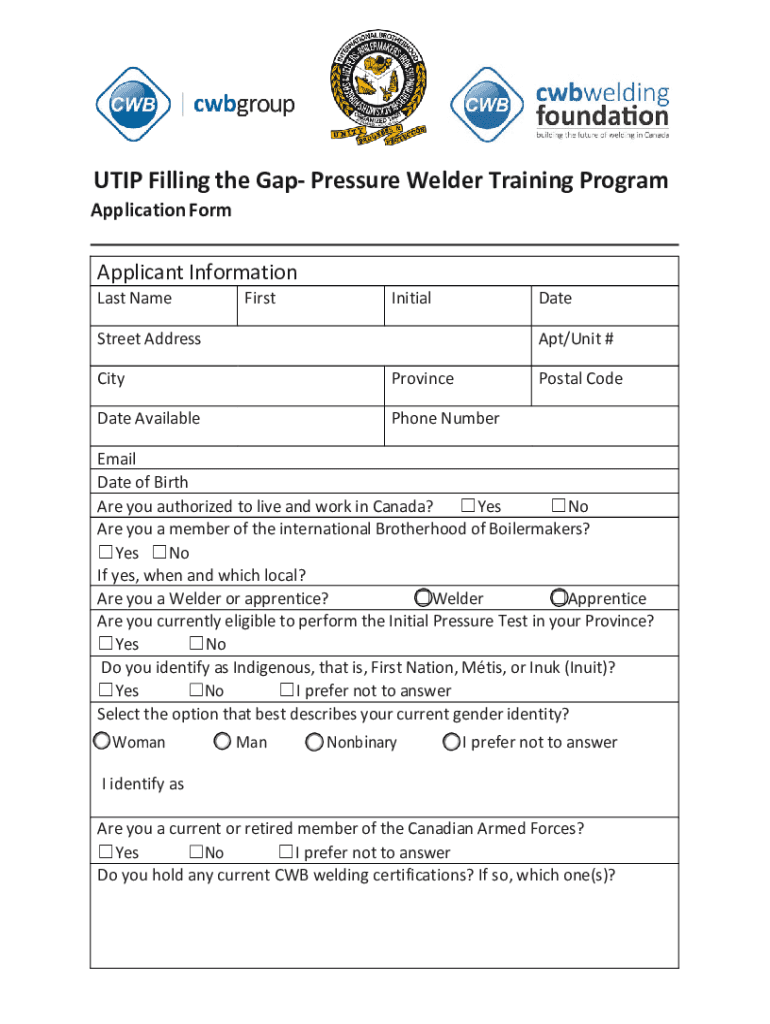

TIP Filling the Gap Pressure Welder Training ProgramApplication FormApplicant Information Last NameFirstInitialDateStreet Address/Unit #CityProvincePostal CodeD ate AvailablePhone NumberEmail Date

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign filling form gap-pressure welding

Edit your filling form gap-pressure welding form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your filling form gap-pressure welding form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit filling form gap-pressure welding online

Use the instructions below to start using our professional PDF editor:

1

Check your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit filling form gap-pressure welding. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

With pdfFiller, it's always easy to deal with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out filling form gap-pressure welding

How to fill out filling form gap-pressure welding

01

To fill out a filling form for gap-pressure welding, follow these steps:

02

Start by cleaning the gap between the two metal surfaces that need to be welded. Remove any dirt, rust, or contaminants.

03

Measure the width and depth of the gap. This will help determine the amount of filler material needed.

04

Choose an appropriate filler material for the specific metals being welded. Consult a welding expert or refer to welding guidelines for the best choice.

05

Pre-heat the gap if necessary, especially for thicker metal plates. This helps ensure proper bonding and reduces the risk of defects.

06

Prepare the filler material according to the manufacturer's instructions. This may involve cutting it into the proper shape or form.

07

Place the filler material evenly across the gap. Avoid any gaps or overlaps that may compromise the weld quality.

08

Apply pressure to the filler material using a specialized tool or welding equipment. The pressure should be sufficient to ensure proper bonding.

09

Allow the filler material to cool down and solidify, forming a strong bond between the metal surfaces.

10

Inspect the weld for any defects or irregularities. If necessary, perform any additional finishing or post-welding treatments.

11

Finally, clean the welded area and remove any residues or leftover material.

Who needs filling form gap-pressure welding?

01

Filling form gap-pressure welding is commonly used in various industries including:

02

- Automotive: For joining metal components in car bodies, chassis, and pipelines.

03

- Aerospace: For welding aircraft components and structures that require strong and precise bonding.

04

- Construction: For welding metal structures, beams, and frames in buildings and infrastructure projects.

05

- Manufacturing: For fabricating metal products, equipment, and machinery.

06

- Energy: For welding pipelines, pressure vessels, and other critical components in the oil and gas industry.

07

In summary, anyone involved in metal fabrication, construction, or manufacturing industries may need filling form gap-pressure welding.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify filling form gap-pressure welding without leaving Google Drive?

By combining pdfFiller with Google Docs, you can generate fillable forms directly in Google Drive. No need to leave Google Drive to make edits or sign documents, including filling form gap-pressure welding. Use pdfFiller's features in Google Drive to handle documents on any internet-connected device.

How do I make changes in filling form gap-pressure welding?

The editing procedure is simple with pdfFiller. Open your filling form gap-pressure welding in the editor, which is quite user-friendly. You may use it to blackout, redact, write, and erase text, add photos, draw arrows and lines, set sticky notes and text boxes, and much more.

Can I edit filling form gap-pressure welding on an Android device?

The pdfFiller app for Android allows you to edit PDF files like filling form gap-pressure welding. Mobile document editing, signing, and sending. Install the app to ease document management anywhere.

What is filling form gap-pressure welding?

Filling form gap-pressure welding is a specialized welding technique used to join materials by applying pressure and adding a filler material to close the gap between the surfaces being welded.

Who is required to file filling form gap-pressure welding?

Manufacturers and contractors who utilize gap-pressure welding in their operations are required to file the filling form.

How to fill out filling form gap-pressure welding?

To fill out the filling form for gap-pressure welding, individuals must provide details such as the type of materials being welded, specifications of the welding process, and relevant safety information.

What is the purpose of filling form gap-pressure welding?

The purpose of filling the form is to ensure compliance with safety regulations and to document the welding process for quality assurance and regulatory review.

What information must be reported on filling form gap-pressure welding?

The information that must be reported includes details about the materials, the welding process, the qualifications of the operators, and any safety measures taken.

Fill out your filling form gap-pressure welding online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Filling Form Gap-Pressure Welding is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.