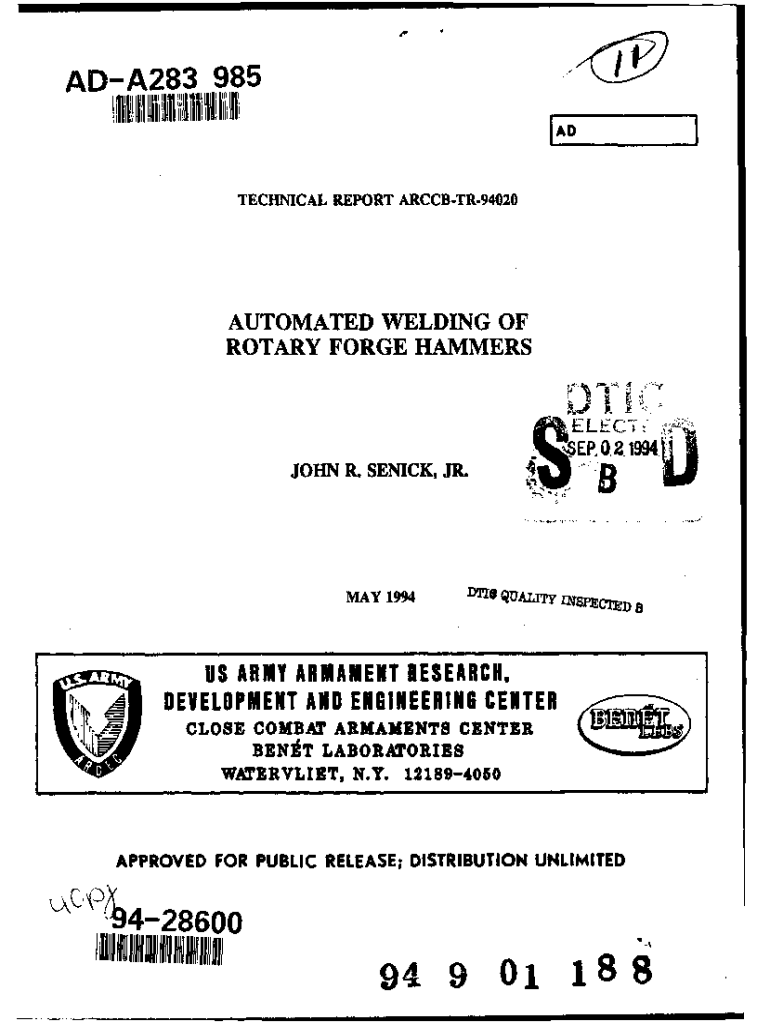

Get the free Automated Welding of Rotary Forge Hammers. The process development and implementatio...

Show details

1ljlIiiil! IlADA283 li ]/II985 lliii !IIlI___.,___IADTECHNICAL REPORT ARCCBTR94020AUTOMATED WELDING OF ROTARY FORGE HAMMERSEPR 0.,?. 1994ij JOHN R. SENICK, JR.MAY 1994BDMGqUALITYZCMDUS ARMY ARMAMENT

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign automated welding of rotary

Edit your automated welding of rotary form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your automated welding of rotary form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing automated welding of rotary online

To use the professional PDF editor, follow these steps:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit automated welding of rotary. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

The use of pdfFiller makes dealing with documents straightforward. Now is the time to try it!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out automated welding of rotary

How to fill out automated welding of rotary

01

Set up the rotary welding machine in a safe and stable position.

02

Prepare the materials for welding, including the metal parts to be welded and the welding wire.

03

Clean the metal parts to remove any dirt, rust, or debris that could affect the quality of the welding.

04

Set the parameters on the welding machine according to the specific requirements of the welding process, such as voltage, amperage, and wire feed speed.

05

Place the metal parts to be welded in the correct position on the rotary welding machine, ensuring proper alignment for optimal welding results.

06

Start the welding process by initiating the arc and allowing the welding wire to melt and form a bond between the metal parts.

07

Control the speed and rotation of the rotary welding machine to ensure even and consistent welding throughout the joint.

08

Monitor the welding process closely, checking for any defects or irregularities that may require adjustment or interruption of the welding.

09

Allow the welded joint to cool down gradually to avoid any sudden temperature changes that could lead to stress or distortion.

10

Inspect the welded joint for quality and integrity, ensuring that it meets the required specifications and standards.

11

If necessary, perform any post-welding treatments or finishing processes, such as grinding, polishing, or painting.

12

Safely remove the welded assembly from the rotary welding machine and perform any necessary cleaning or maintenance to keep the equipment in good working condition.

Who needs automated welding of rotary?

01

Automated welding of rotary is suited for industries that require high precision and efficiency in welding cylindrical or curved components.

02

Industries such as automotive, aerospace, oil and gas, and heavy machinery often utilize automated rotary welding for applications like pipe fabrication, tank construction, or structural welding of curved metal parts.

03

Companies that need to streamline their production process, increase welding productivity, and maintain consistent quality standards can benefit from automated welding of rotary.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my automated welding of rotary in Gmail?

You may use pdfFiller's Gmail add-on to change, fill out, and eSign your automated welding of rotary as well as other documents directly in your inbox by using the pdfFiller add-on for Gmail. pdfFiller for Gmail may be found on the Google Workspace Marketplace. Use the time you would have spent dealing with your papers and eSignatures for more vital tasks instead.

How can I edit automated welding of rotary from Google Drive?

By integrating pdfFiller with Google Docs, you can streamline your document workflows and produce fillable forms that can be stored directly in Google Drive. Using the connection, you will be able to create, change, and eSign documents, including automated welding of rotary, all without having to leave Google Drive. Add pdfFiller's features to Google Drive and you'll be able to handle your documents more effectively from any device with an internet connection.

Can I create an eSignature for the automated welding of rotary in Gmail?

Use pdfFiller's Gmail add-on to upload, type, or draw a signature. Your automated welding of rotary and other papers may be signed using pdfFiller. Register for a free account to preserve signed papers and signatures.

What is automated welding of rotary?

Automated welding of rotary refers to a mechanized process where welding is performed on rotary components using automated systems to enhance precision and efficiency.

Who is required to file automated welding of rotary?

Manufacturers and service providers engaged in the automated welding of rotary components are typically required to file necessary documentation.

How to fill out automated welding of rotary?

Filling out automated welding of rotary involves providing required details such as process specifications, safety measures, and compliance documentation as per governing regulations.

What is the purpose of automated welding of rotary?

The purpose of automated welding of rotary is to ensure high-quality welds, reduce human error, increase production speed, and maintain consistency in the welding process.

What information must be reported on automated welding of rotary?

Information that must be reported includes the welding parameters used, material specifications, quality control tests, and certifications related to the welding process.

Fill out your automated welding of rotary online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Automated Welding Of Rotary is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.