Get the free MIG Welding Wire Feeders - Linde Gas & Equipment

Show details

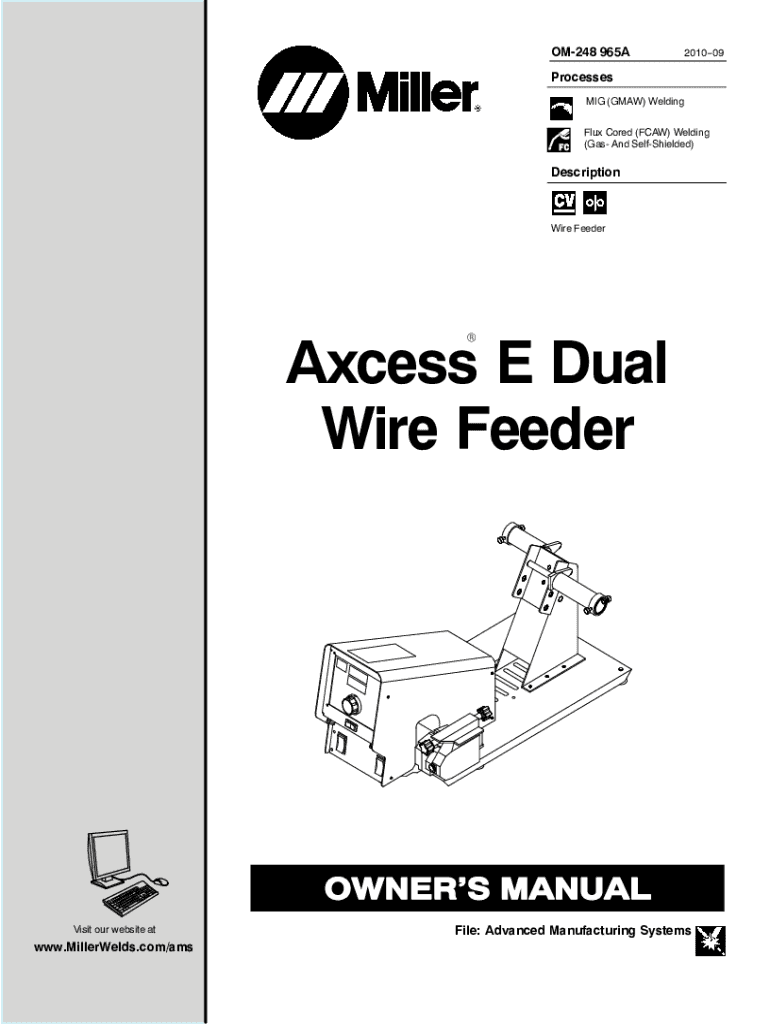

OM248 965A201009Processes

MIG (GMAC) Welding

Flux Cored (FLAW) Welding

(Gas And SelfShielded)DescriptionWire FeederAxcess E Dual

Wire Feeder

Visit our website atwww.MillerWelds.com/amsFile: Advanced

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign mig welding wire feeders

Edit your mig welding wire feeders form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your mig welding wire feeders form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit mig welding wire feeders online

To use our professional PDF editor, follow these steps:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit mig welding wire feeders. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

With pdfFiller, dealing with documents is always straightforward.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out mig welding wire feeders

How to fill out mig welding wire feeders

01

Gather all the necessary equipment: mig welding machine, welding wire feeder, wire, welding gun, and welding helmet.

02

Ensure the welding machine is turned off and the power source is disconnected.

03

Connect the wire feeder to the welding machine by attaching the appropriate cables.

04

Load the wire onto the wire feeder spool, ensuring it is properly aligned and secured.

05

Set the appropriate wire feed speed on the wire feeder according to the welding requirements.

06

Insert the wire into the welding gun's wire guide and secure it in place.

07

Connect the welding gun to the wire feeder using the appropriate cable connectors.

08

Put on the welding helmet and other safety equipment.

09

Turn on the welding machine and adjust the voltage and amperage settings according to the material and thickness being welded.

10

Hold the welding gun at the correct angle and distance from the workpiece.

11

Start welding by pulling the trigger on the welding gun, allowing the wire feeder to automatically feed the wire as you move along the joint.

12

Maintain a steady motion and manipulate the angle and distance of the gun to achieve the desired weld.

13

After finishing welding, release the trigger and allow the wire feeder to retract the wire.

14

Turn off the welding machine and disconnect the power source.

15

Clean and inspect the weld for any defects or imperfections.

16

Practice and hone your mig welding skills to improve your technique.

Who needs mig welding wire feeders?

01

Mig welding wire feeders are needed by professionals and hobbyists who perform mig welding.

02

Industries such as automotive, manufacturing, construction, and metal fabrication often require mig welding wire feeders.

03

Welders who work with steel, stainless steel, and aluminum find mig welding wire feeders indispensable.

04

Individuals and businesses that need to join metal parts together for structural or aesthetic purposes can benefit from mig welding wire feeders.

05

Whether for repairing, constructing, or fabricating, anyone working with mig welding can benefit from the use of wire feeders.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get mig welding wire feeders?

The pdfFiller premium subscription gives you access to a large library of fillable forms (over 25 million fillable templates) that you can download, fill out, print, and sign. In the library, you'll have no problem discovering state-specific mig welding wire feeders and other forms. Find the template you want and tweak it with powerful editing tools.

How do I edit mig welding wire feeders online?

The editing procedure is simple with pdfFiller. Open your mig welding wire feeders in the editor, which is quite user-friendly. You may use it to blackout, redact, write, and erase text, add photos, draw arrows and lines, set sticky notes and text boxes, and much more.

Can I create an electronic signature for signing my mig welding wire feeders in Gmail?

Use pdfFiller's Gmail add-on to upload, type, or draw a signature. Your mig welding wire feeders and other papers may be signed using pdfFiller. Register for a free account to preserve signed papers and signatures.

What is mig welding wire feeders?

MIG welding wire feeders are devices that supply continuous lengths of welding wire to the welding process, ensuring a steady flow of material for efficient welding.

Who is required to file mig welding wire feeders?

Typically, those who engage in MIG welding operations and are utilizing wire feeders for their welding processes are required to file related documentation for regulatory or safety compliance.

How to fill out mig welding wire feeders?

Filling out MIG welding wire feeders involves documenting key information such as wire type, diameter, usage statistics, and any safety inspections, following specific guidelines provided by regulatory bodies.

What is the purpose of mig welding wire feeders?

The purpose of MIG welding wire feeders is to ensure a consistent and controllable feed of welding wire, enhancing the quality and efficiency of the welding process.

What information must be reported on mig welding wire feeders?

Information that must be reported includes the type of welding wire used, the volume consumed, equipment details, operator information, and any incident reports or safety evaluations.

Fill out your mig welding wire feeders online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Mig Welding Wire Feeders is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.