Get the free TYPICAL WELD METAL PROPERTIES* (Wire Chemistry)

Show details

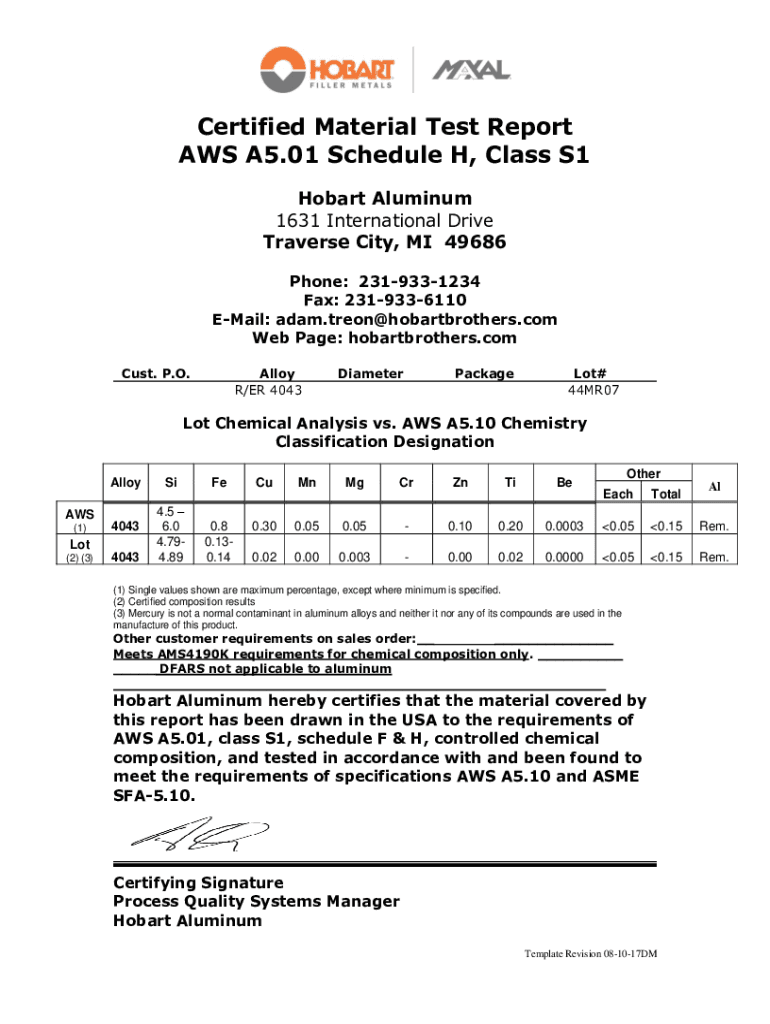

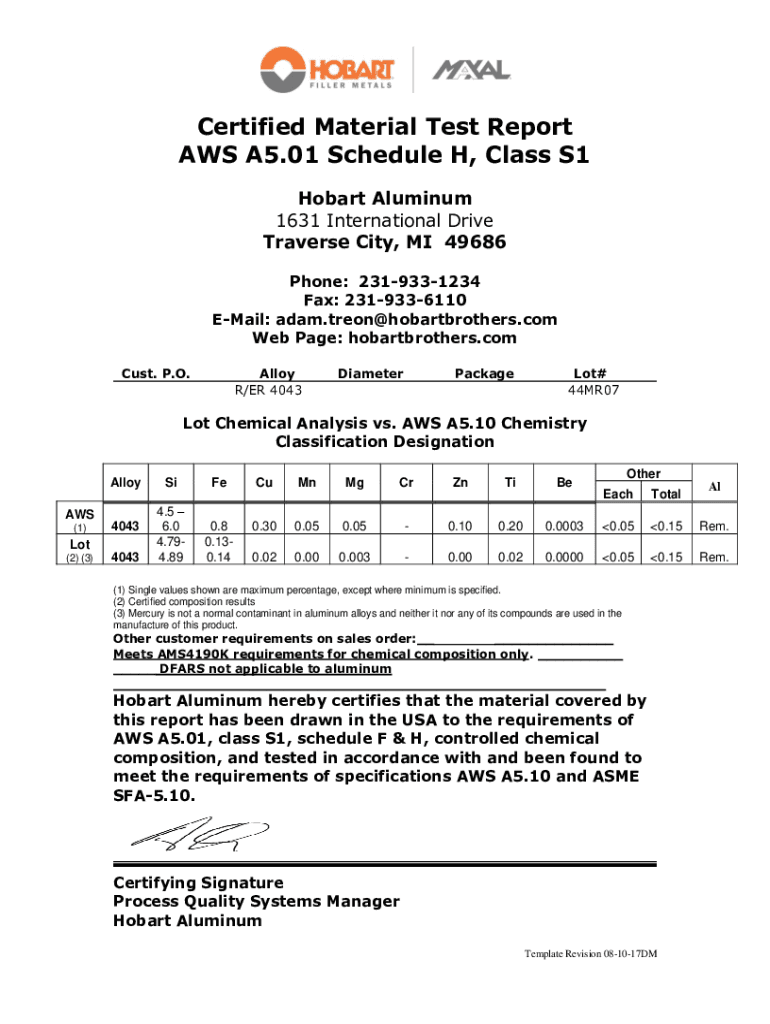

Certified Material Test Report AWS A5.01 Schedule H, Class S1 Hobart Aluminum 1631 International Drive Traverse City, MI 49686 Phone: 2319331234 Fax: 2319336110 EMail: adam.treon@hobartbrothers.com

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign typical weld metal properties

Edit your typical weld metal properties form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your typical weld metal properties form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing typical weld metal properties online

To use the services of a skilled PDF editor, follow these steps below:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit typical weld metal properties. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out typical weld metal properties

How to fill out typical weld metal properties

01

Identify the type of welding process being used for the project.

02

Determine the required mechanical properties for the weld metal.

03

Select the appropriate filler metal based on the welding process and mechanical properties needed.

04

Ensure proper cleaning and preparation of the base metals before welding.

05

Follow the recommended welding parameters and techniques for the selected filler metal.

06

After welding, test the weld metal properties through destructive and non-destructive testing methods.

07

Make any necessary adjustments or repairs to achieve the desired weld metal properties.

Who needs typical weld metal properties?

01

Welders

02

Welding inspectors

03

Quality control personnel

04

Engineers

05

Fabricators

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my typical weld metal properties in Gmail?

Using pdfFiller's Gmail add-on, you can edit, fill out, and sign your typical weld metal properties and other papers directly in your email. You may get it through Google Workspace Marketplace. Make better use of your time by handling your papers and eSignatures.

How can I modify typical weld metal properties without leaving Google Drive?

It is possible to significantly enhance your document management and form preparation by combining pdfFiller with Google Docs. This will allow you to generate papers, amend them, and sign them straight from your Google Drive. Use the add-on to convert your typical weld metal properties into a dynamic fillable form that can be managed and signed using any internet-connected device.

Can I create an eSignature for the typical weld metal properties in Gmail?

Use pdfFiller's Gmail add-on to upload, type, or draw a signature. Your typical weld metal properties and other papers may be signed using pdfFiller. Register for a free account to preserve signed papers and signatures.

What is typical weld metal properties?

Typical weld metal properties include mechanical characteristics such as tensile strength, yield strength, ductility, toughness, and hardness. These properties ensure the weld can withstand service conditions and support structural integrity.

Who is required to file typical weld metal properties?

Welders, welding engineers, and quality control personnel responsible for ensuring compliance with welding standards and specifications are required to file typical weld metal properties.

How to fill out typical weld metal properties?

To fill out typical weld metal properties, one should gather test results for mechanical properties, chemical composition, and any pertinent details about the welding process used. This information is then recorded in a standardized format or form as required by the applicable codes or standards.

What is the purpose of typical weld metal properties?

The purpose of typical weld metal properties is to provide essential data that ensures welds meet specified quality and performance standards, ultimately ensuring safety and reliability in structural applications.

What information must be reported on typical weld metal properties?

Reported information typically includes weld metal type, chemical composition, mechanical properties (such as tensile and yield strength), heat treatment details, and any testing methods used to verify properties.

Fill out your typical weld metal properties online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Typical Weld Metal Properties is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.