Get the free PLASTIC PIPE, FITTINGS, VALVES & SOLVENT CEMENTS

Get, Create, Make and Sign plastic pipe fittings valves

Editing plastic pipe fittings valves online

Uncompromising security for your PDF editing and eSignature needs

How to fill out plastic pipe fittings valves

How to fill out plastic pipe fittings valves

Who needs plastic pipe fittings valves?

Plastic Pipe Fittings Valves Form: A Comprehensive Guide

Understanding plastic pipe fittings and valves

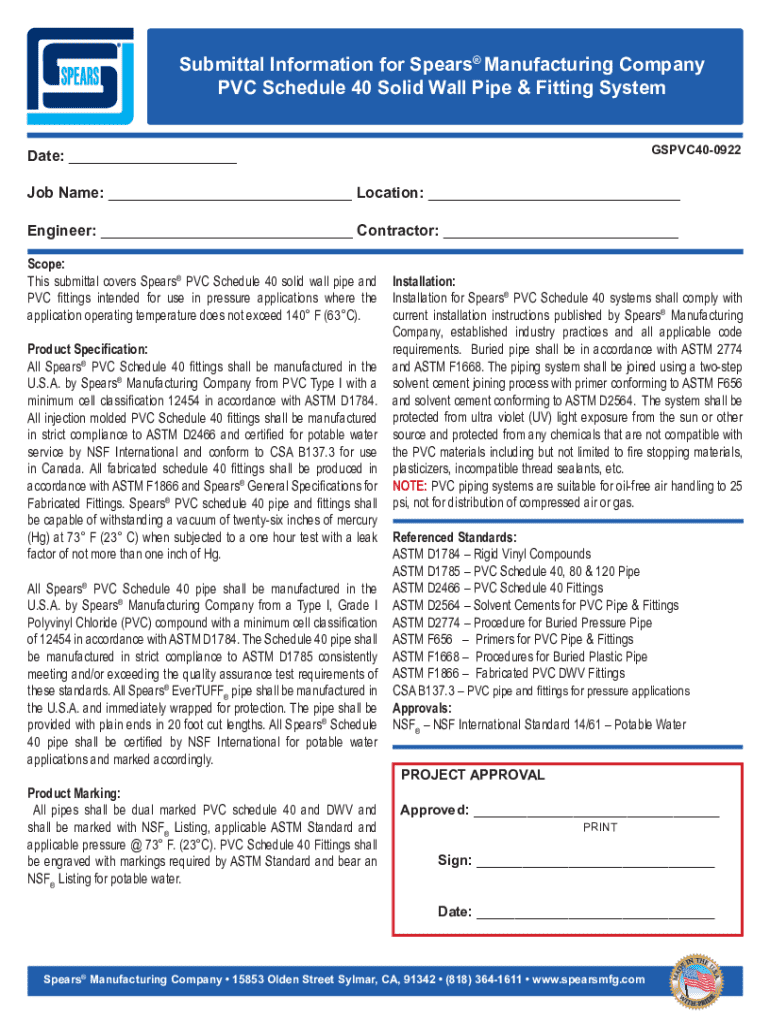

Plastic pipe fittings and valves are integral components used to connect different sections of plastic piping systems. These fittings and valves help to control the flow of fluids, allowing for seamless transportation in both residential and industrial applications. The use of the correct fittings and valves is crucial in maintaining system integrity and efficiency, as improper selections can lead to leaks, failures, and costly repairs.

When compared to traditional materials such as metal or rubber, plastic offers several advantages, including corrosion resistance, lightweight properties, and lower material costs. This makes plastic fittings particularly appealing for various plumbing and construction projects.

Types of plastic pipe fittings

Plastic pipe fittings come in various types, each serving specific functions within a piping system. Understanding these types is essential for selecting the right fittings for your project.

Each type of fitting serves distinct application scenarios. For instance, elbow fittings are essential in situations where space constraints require turning a piping run quickly. In contrast, unions are invaluable in setups where frequent disassembly and maintenance are necessary.

Understanding valve connections

Valves are devices used to regulate the flow of fluid in a piping system. They can be found in various applications ranging from household plumbing to large industrial systems. Selecting the appropriate valve type is critical for ensuring effective control and system performance.

Understanding the functions and applications of these valves will help you make informed choices for your project.

Selecting the right connection type for your project

Choosing the correct fittings and valves involves several key considerations to ensure optimal performance in your plumbing or construction project. Each factor impacts the overall efficiency and longevity of your piping system.

Here’s a step-by-step guide to making informed selections: 1. Determine system requirements based on your project needs. 2. Identify applicable fittings and valves based on function and compatibility. 3. Consider installation constraints related to space and accessibility. 4. Evaluate future maintenance needs to facilitate ease of access.

Installation guidelines for plastic pipe fittings and valves

Proper installation of your plastic pipe fittings and valves is paramount for achieving a leak-free and efficient system. Preparation is key, involving specific tools and adherence to safety protocols to ensure a successful installation.

Follow these installation steps: 1. Cut pipes to the required length with a pipe cutter for clean edges. 2. Clean and prepare pipe ends by removing burrs to ensure a tight fit. 3. Apply adhesive or sealant as per the fitting's requirements. 4. Connect fittings and valves securely, ensuring proper alignment. 5. Test for leaks post-installation by pressurizing the system.

Adhering to best practices, such as double-checking connections for tightness and avoiding over-tightening, will significantly reduce common installation errors.

Maintenance tips for plastic pipe fittings and valves

To prolong the service life of your plastic pipe fittings and valves, regular maintenance is essential. Establishing a routine of inspection and care can help detect issues early and significantly prevent costly repairs down the line.

Consistent maintenance practices will keep your fittings and valves functioning efficiently, safeguarding your plumbing system.

Innovative solutions and tools offered by pdfFiller

In the realm of document management, pdfFiller provides innovative tools tailored for professionals in plumbing and construction, enhancing their workflow. Whether you need to create, edit, or manage documents related to your projects, pdfFiller’s comprehensive features elevate your documentation processes.

Utilizing these tools for project documentation means you can work from anywhere, embracing the power of cloud-based technology to stay organized and efficient.

Case studies and real-world applications

Examining successful case studies helps to illustrate the practical applications of plastic pipe fittings and valves. For instance, in a recent municipal water project, the adoption of plastic fittings led to a significant reduction in corrosion-related failures and decreased overall maintenance costs. Each project can provide insights into best practices and lessons learned.

Additionally, integrating pdfFiller into these projects facilitated smoother document workflows, ensuring that all approvals and documentation were managed efficiently despite remote working conditions.

Environmental considerations in choosing plastic fittings

The sustainability of plastic materials is often debated, yet many modern plastics are designed for longevity and reduced environmental impact. Current innovations include bio-based plastics and enhanced recycling processes that minimize waste.

These considerations can significantly impact your project choices, ensuring environmentally responsible decisions are made.

Future trends in plastic pipe fitting and valve technology

As technology continues to advance, the industry is witnessing new materials and design innovations for plastic pipe fittings and valves. Emerging trends include the development of higher-strength, lighter materials that can handle extreme pressures and temperatures.

Keeping an eye on these trends is crucial for professionals to stay ahead and ensure that projects are supported by the latest technology and materials.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my plastic pipe fittings valves in Gmail?

Can I create an electronic signature for signing my plastic pipe fittings valves in Gmail?

How can I fill out plastic pipe fittings valves on an iOS device?

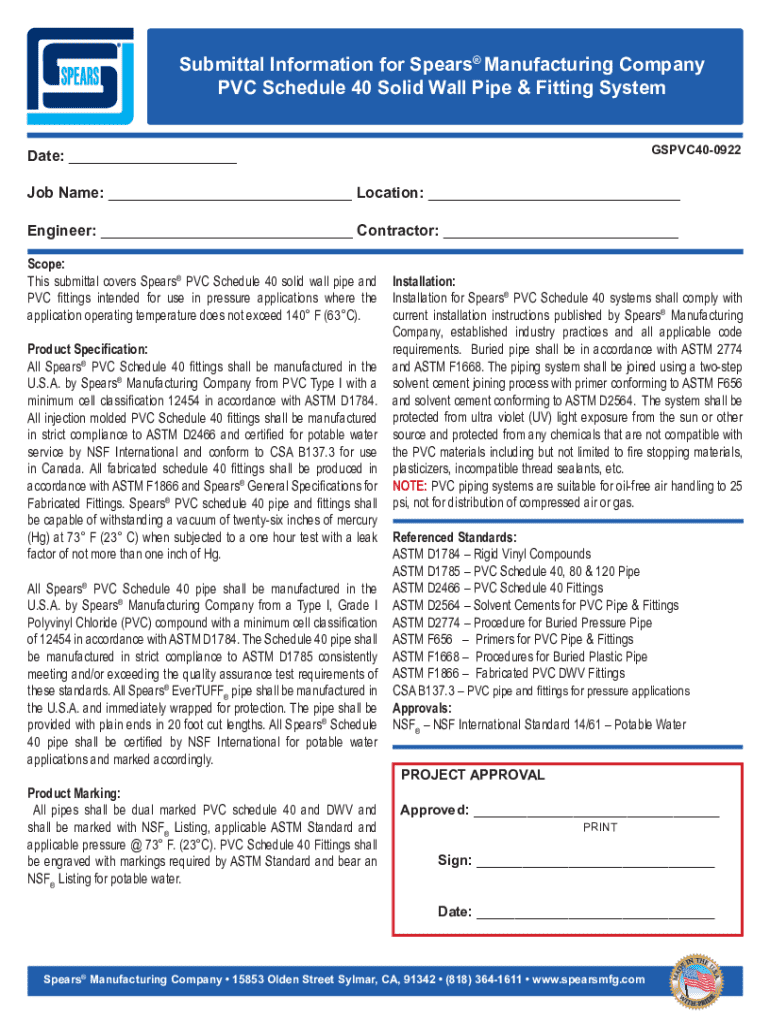

What is plastic pipe fittings valves?

Who is required to file plastic pipe fittings valves?

How to fill out plastic pipe fittings valves?

What is the purpose of plastic pipe fittings valves?

What information must be reported on plastic pipe fittings valves?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.