Get the free OPTIMISATION OF INJECTION MOULDING - umpir ump edu

Show details

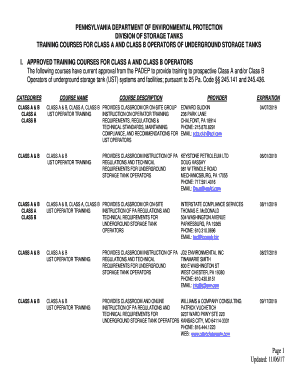

OPTIMISATION OF INJECTION MOULDING PROCESS PARAMETERS USING TAGUCHI AND DESIRABILITY FUNCTIONVIVEKANANDAN A/L PANNEERSELVAMMASTER OF SCIENCE UNIVERSITI MALAYSIA PAHANGSUPERVISORS DECLARATION I hereby

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign optimisation of injection moulding

Edit your optimisation of injection moulding form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your optimisation of injection moulding form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing optimisation of injection moulding online

Use the instructions below to start using our professional PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit optimisation of injection moulding. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

It's easier to work with documents with pdfFiller than you could have believed. You can sign up for an account to see for yourself.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out optimisation of injection moulding

How to fill out optimisation of injection moulding

01

Identify the current issues in the injection moulding process, such as defects or inefficiencies.

02

Collect data on the existing process parameters, including temperature, pressure, and cycle times.

03

Analyze the material properties and specifications of the injected materials.

04

Conduct experiments or simulations to determine optimal settings for the moulding process.

05

Implement changes gradually while monitoring the outputs and quality of the products.

06

Evaluate the performance of the optimized process through quality control checks.

07

Make further adjustments as necessary based on feedback and results.

Who needs optimisation of injection moulding?

01

Manufacturers involved in producing plastic components through injection moulding.

02

Companies looking to improve product quality and reduce production costs.

03

Injection moulding engineers and technicians working on optimising production processes.

04

Quality assurance teams focused on minimizing defects in finished products.

05

R&D departments aiming to innovate or enhance material formulations and processes.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify optimisation of injection moulding without leaving Google Drive?

You can quickly improve your document management and form preparation by integrating pdfFiller with Google Docs so that you can create, edit and sign documents directly from your Google Drive. The add-on enables you to transform your optimisation of injection moulding into a dynamic fillable form that you can manage and eSign from any internet-connected device.

How can I send optimisation of injection moulding for eSignature?

When you're ready to share your optimisation of injection moulding, you can send it to other people and get the eSigned document back just as quickly. Share your PDF by email, fax, text message, or USPS mail. You can also notarize your PDF on the web. You don't have to leave your account to do this.

Can I edit optimisation of injection moulding on an Android device?

With the pdfFiller Android app, you can edit, sign, and share optimisation of injection moulding on your mobile device from any place. All you need is an internet connection to do this. Keep your documents in order from anywhere with the help of the app!

What is optimisation of injection moulding?

Optimisation of injection moulding refers to the process of refining and enhancing the injection moulding process to achieve higher efficiency, reduce waste, improve product quality, and lower production costs. This can involve adjustments to machine settings, tooling, material selection, and process parameters.

Who is required to file optimisation of injection moulding?

Typically, manufacturers and production engineers involved in the injection moulding process are required to file optimisation reports. This may also include quality assurance personnel and regulatory compliance officers, depending on industry standards.

How to fill out optimisation of injection moulding?

Filling out optimisation of injection moulding involves documenting the settings and parameters used during the injection moulding process, analyzing key performance indicators, and noting any modifications made. A structured report should include details such as material used, machine settings, cycle time, and quality metrics.

What is the purpose of optimisation of injection moulding?

The purpose of optimisation of injection moulding is to enhance the overall production process by minimizing defects, maximizing throughput, reducing cycle times, and ensuring consistency in product quality. Ultimately, it aims to increase profitability and competitiveness in the market.

What information must be reported on optimisation of injection moulding?

Information that must be reported includes machine settings (temperature, pressure, cycle times), type of materials used, product specifications, quality control results, any changes made during the process, and efficiency metrics. Additionally, records of any defects or production issues should be documented.

Fill out your optimisation of injection moulding online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Optimisation Of Injection Moulding is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.