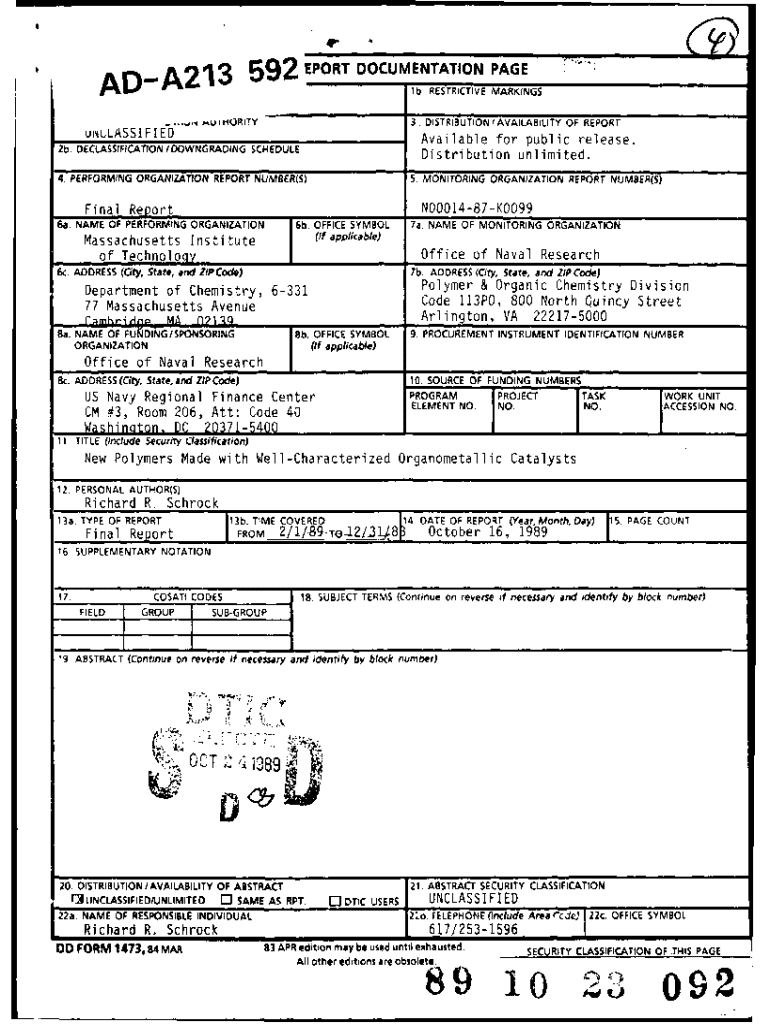

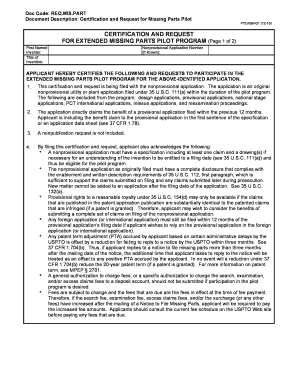

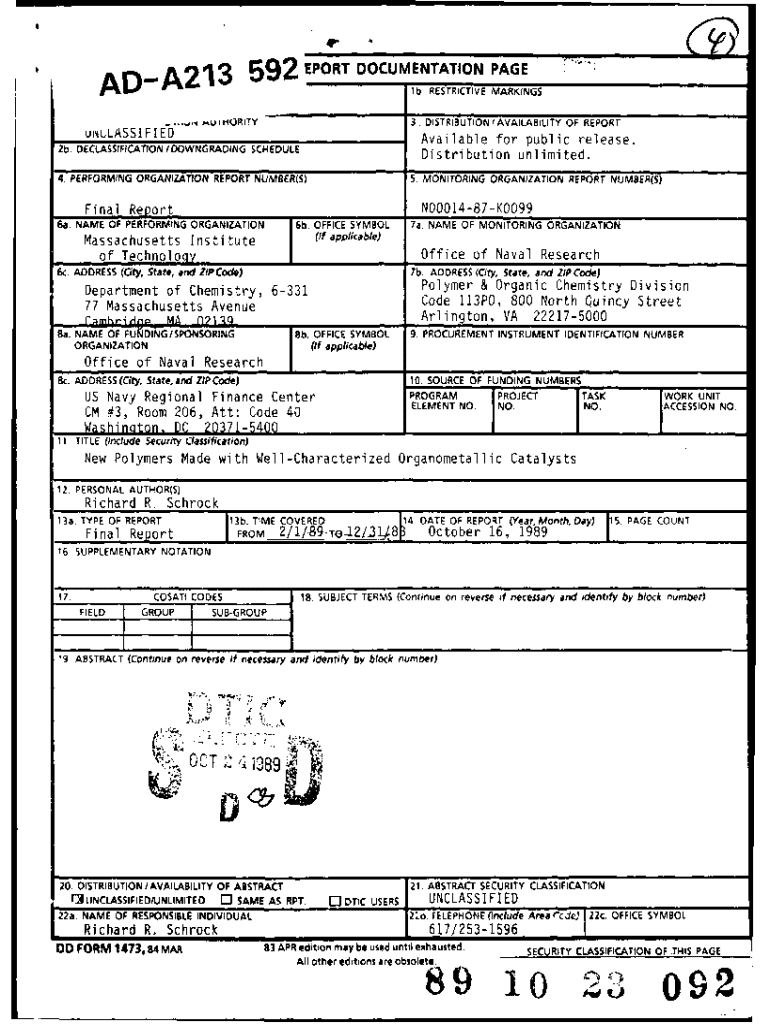

Get the free New Polymers Made With Well-characterized Organometallic Catalysts

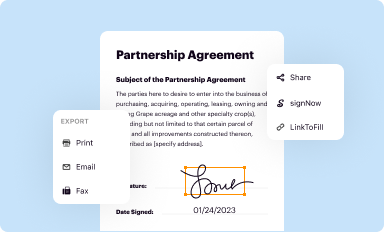

Get, Create, Make and Sign new polymers made with

How to edit new polymers made with online

Uncompromising security for your PDF editing and eSignature needs

How to fill out new polymers made with

How to fill out new polymers made with

Who needs new polymers made with?

New polymers made with form: A comprehensive guide

Understanding the basics of new polymers

Polymers are large molecules composed of repeating structural units known as monomers. These versatile materials range from natural substances like rubber and silk to synthetic options such as nylon and polyurethane. New polymers, particularly those enhanced with form, represent an exciting frontier in materials science.

The importance of new polymers cannot be overstated. They are integral to numerous industries, enabling innovations in product design and manufacturing processes. For example, polymers are essential in automotive parts, electronic devices, and medical supplies, providing the durability and flexibility needed in today's high-performance settings.

Understanding the science behind polymer formation involves recognizing the chemical processes that create these materials. Polymer synthesis typically takes place through various chemical reactions, primarily addition and condensation. Factors such as temperature, pressure, and the choice of monomers significantly influence the properties of the resulting polymer.

Innovative applications of new polymers

New polymers find applications across multiple industries, showcasing their adaptability and performance. In the aerospace sector, lightweight polymers improve fuel efficiency without compromising structural integrity. Similarly, in automotive manufacturing, polymers contribute to reducing vehicle weight and enhancing fuel economy.

In healthcare, polymers like biodegradable sutures and drug delivery systems are revolutionizing patient care. These advancements are not only enhancing the performance of medical devices but also addressing environmental concerns by reducing medical waste. The shift toward sustainable materials is crucial as the industry seeks to lessen its ecological footprint.

Techniques for creating new polymers

Creating new polymers involves various polymerization methods that define their characteristics. Addition polymerization, a significant technique, involves combining monomers with unsaturated bonds without losing any atoms. In contrast, condensation polymerization results in the expulsion of small molecules, like water, during the reaction. Understanding each method enables scientists to tailor the polymer's attributes for specific applications.

Recent advancements, such as 3D printing of polymers, have opened new avenues for customization. This technique allows for the creation of complex structures, which traditional casting methods may not achieve. These innovations enable greater creativity in design and functionality for various applications, from consumer goods to specialized medical equipment.

Formulating new polymers: A step-by-step guide

The formulation of new polymers is a systematic process requiring careful consideration of several factors. Step one involves selecting the right raw materials, including monomers and additives. Choosing the correct components is crucial, as compatibility affects the final product's properties. The diversity of available monomers allows for variety in properties, from strength to thermal resistance.

Next, measuring and mixing the ingredients accurately is vital. Precision tools, such as digital scales and volumetric flasks, help ensure the correct proportions are used. After mixing, the polymerization process begins. During this phase, monitoring conditions like temperature and pressure is crucial to achieve the desired molecular weight and characteristics. Finally, post-processing techniques shape and finish the polymer, ensuring it meets the required specifications.

Innovative formulations and their impacts

Breakthroughs in polymer chemistry have led to the development of materials with unique properties that were previously unattainable. For example, researchers have developed self-healing polymers, which can repair themselves after damage, extending the lifespan of products and minimizing waste. Such innovations not only enhance product performance but also align with sustainability goals.

Real-world outcomes illustrate the performance benefits of new polymers. Increased durability, lightweight structures, and adaptability contribute to the success of industries adopting these advanced materials. Testimonials from professionals highlight the positive impact these innovations have made in their respective fields, revolutionizing the way products are designed and utilized.

Tools and resources for polymer development

The formulation and development of new polymers can greatly benefit from interactive tools. Sophisticated software and platforms are available to support polymer design, enabling scientists and engineers to model and test various formulations digitally. These tools facilitate quick iterations, reducing the time involved in the R&D process while allowing for greater innovation.

Collaboration is vital in this field, hence community and support systems are essential. Forums and networks foster shared learning and problem-solving among professionals in polymer sciences, enhancing overall knowledge and resources available to individuals and teams. Connection between scientists and engineers often leads to breakthroughs that drive the industry forward.

Future trends in polymer innovation

Research into new polymers is an active area of exploration, with emerging technologies constantly reshaping the landscape. Current research focuses on bio-based polymers that utilize renewable resources, contributing to sustainability goals within the industry. Additionally, advances in nanotechnology are enabling the development of polymers that can perform under extremes of temperature and pressure, opening new possibilities for industrial applications.

Businesses looking to adopt new polymers must strategize carefully. Integrating these materials into product lines requires investment in technology and training, as well as addressing challenges of scaling production to meet demand. Companies that adapt to these trends will likely find themselves positioned competitively in their markets.

Managing documentation for polymer projects

Effective documentation is crucial in polymer production, as accurate record-keeping facilitates quality control and traceability. Establishing systematic documentation practices ensures compliance with industry standards and fosters collaboration among team members. Recommended document templates can streamline the process, making it easier to manage formulations and testing results.

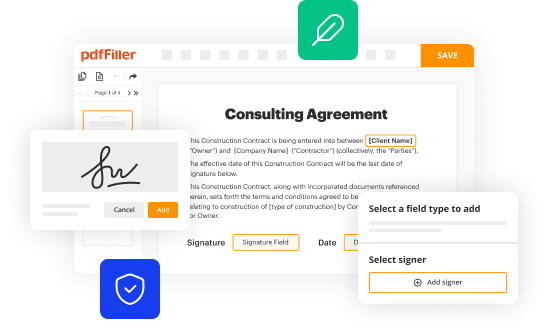

Utilizing tools like pdfFiller enhances document handling throughout the development process. This cloud-based platform allows users to edit PDFs, eSign documents, and collaborate efficiently. By incorporating pdfFiller into polymer projects, teams can manage their documentation seamlessly, ensuring that all relevant information is accessible and up to date.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for signing my new polymers made with in Gmail?

How do I complete new polymers made with on an iOS device?

Can I edit new polymers made with on an Android device?

What is new polymers made with?

Who is required to file new polymers made with?

How to fill out new polymers made with?

What is the purpose of new polymers made with?

What information must be reported on new polymers made with?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.