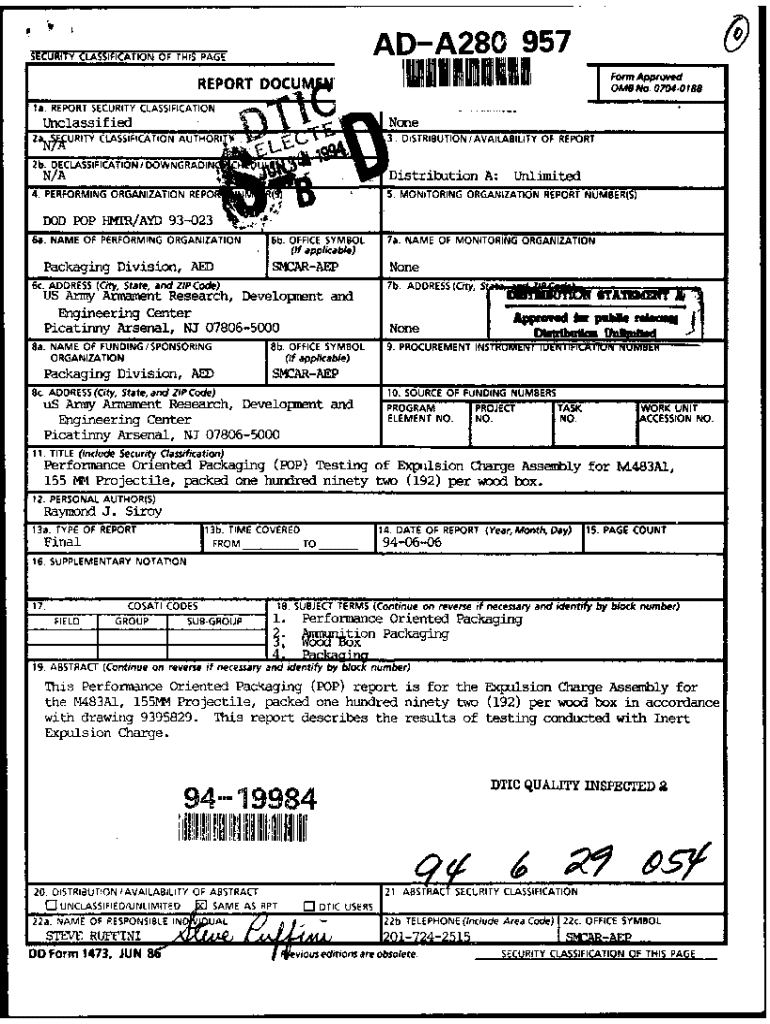

Get the free Performance Oriented Packaging Testing Report

Get, Create, Make and Sign performance oriented packaging testing

Editing performance oriented packaging testing online

Uncompromising security for your PDF editing and eSignature needs

How to fill out performance oriented packaging testing

How to fill out performance oriented packaging testing

Who needs performance oriented packaging testing?

Comprehensive Guide to Performance Oriented Packaging Testing Form

Understanding performance oriented packaging testing

Performance oriented packaging testing (POP testing) is essential for guaranteeing that product packaging meets both functional and regulatory standards. Its primary purpose is to verify that packaging not only preserves the integrity of what's inside but also complies with specific industry regulations. Companies invest in POP testing to ensure that packaging can withstand various conditions, ultimately safeguarding product safety and satisfying consumer expectations.

The objectives of performance oriented packaging testing revolve around confirming packaging durability, product preservation during transit, and regulatory compliance. In turn, effective testing can significantly reduce the risk of product damage, failed inspections, and consumer concerns over safety. The relationship between packaging performance and product safety is direct; an effective package protects its contents, ensuring that products remain safe for consumption or use, which is paramount across diverse industries.

Common packaging test types

There are several key types of tests integral to performance oriented packaging testing, including durability tests, barrier tests, and accelerated aging tests. Each test type serves a unique purpose and targets different aspects of packaging performance.

Preparing for packaging testing

Preparation is crucial when undertaking performance oriented packaging testing. Selecting the right parameters is the first step; this includes determining the test type based on product needs and packaging materials. Each product may necessitate different tests, and understanding the specific requirements based on industry standards is paramount.

Furthermore, it's essential to identify relevant standards and regulations. Key industry guidelines can stem from organizations such as ASTM and ISO, ensuring that you comply with safety and quality protocols. Familiarity with specific standards applicable to your industry will guide your testing methodology. Lastly, understanding which packaging materials need to be tested—whether plastic, glass, or paper—allows for precise evaluations.

Filling out the performance oriented packaging testing form

Filling out the performance oriented packaging testing form accurately is pivotal for effective testing outcomes. Here is a step-by-step guide on how to complete the form.

Interactive tools for packaging testing

Today’s digital landscape offers various interactive tools to streamline the performance oriented packaging testing process. Online calculators for packaging strength allow teams to quickly determine if their packaging meets necessary specifications before testing. Additionally, checklists for preparing samples and forms serve to ensure no detail is overlooked in the application process.

Another valuable tool is a feedback system for interpreting test results. This kind of feedback allows teams to glean actionable insights from testing outcomes and make informed adjustments. Utilizing such resources can significantly enhance the packaging process and ensure compliance with regulatory expectations.

Managing your packaging testing process

Effective management of the packaging testing process ensures that issues are addressed promptly and outcomes are measured properly. Tracking submission status allows stakeholders to stay updated on where their tests are in the queue and expected results timeframe. Many testing laboratories now provide online platforms for real-time tracking.

Understanding report formats is equally important; knowing how to interpret key metrics from test reports can significantly impact follow-up actions. Furthermore, collaborating with testing labs following best practices—like maintaining open lines of communication and being responsive to lab inquiries—ensures a more seamless testing process.

Case studies: Successful performance testing

Examining real-life case studies can shed light on the tangible benefits and potential pitfalls of performance oriented packaging testing. One exemplary case involved a major consumer electronics brand that underwent rigorous drop and compression testing. Their proactive approach led to a redesign of their packaging that ultimately diminished product returns and enhanced customer satisfaction.

Conversely, some companies learned critical lessons from failed tests. For instance, a food packaging manufacturer faced significant challenges when their moisture barrier failed, resulting in product spoilage. The revisions made to reinforce the packaging structure not only addressed immediate concerns but also provided a roadmap for incorporating feedback from future tests into their development processes.

Regulatory compliance and safety standards

Navigating the complex landscape of regulatory compliance is vital for any business involved in packaging products. Understanding compliance requirements across various industries—e.g., food, pharmaceuticals, electronics—is essential. Each sector has its own protocols emphasizing product safety, material specifications, and environmental impact.

Staying updated with regulatory changes is equally important. Organizations like pdfFiller can aid in managing compliance documentation effectively, allowing teams to focus on product development without the anxiety of missing critical regulatory updates and requirements.

Troubleshooting common issues in packaging testing

Despite best efforts, problems can arise during the packaging testing process. One common pitfall involves incomplete or inaccurately filled forms, which can lead to testing delays or failures. To counter these issues, establish a review process where colleagues can cross-check forms before submission.

Solutions to prevent test failures also include proactive communication with testing labs, clarification of testing protocols, and adhering strictly to submission guidelines. Additionally, setting up a dedicated FAQ section on your dashboard for addressing shared concerns and questions can drastically improve understanding and compliance across your team.

The future of packaging testing

Emerging trends in packaging testing technology signal a shift towards greater efficiency and sustainability. As consumer awareness grows, businesses are increasingly adopting sustainable materials and practices for packaging, necessitating innovative testing methods that align with these new materials. The incorporation of IoT devices into testing methodologies is likely to provide real-time insights into packaging performance, pushing the boundaries of conventional testing.

Equally crucial is preparing for upcoming regulations; as global health and environmental concerns evolve, packaging standards will also adapt. Engaging with dynamic testing forms helps organizations stay ahead of regulatory demands and maintain compliance across their packaging processes.

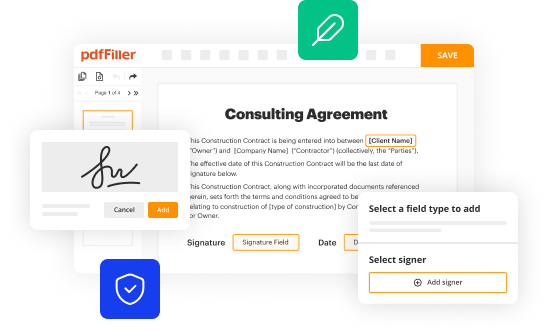

Empowering your document management

Efficient document management is critical for navigating the complex requirements surrounding performance oriented packaging testing. pdfFiller provides seamless editing and electronic signing features that simplify the process of filling out forms. Collaborating on documents can become significantly easier when teams utilize cloud-based solutions, allowing for real-time access and efficient management of vital paperwork.

By effectively utilizing pdfFiller’s document management solutions, businesses can enhance their operational workflows, ensuring that everyone on the team is on the same page and that compliance documentation is readily accessible.

User insights and experiences

Engaging with performance oriented packaging testing forms has proven transformative for many users. Testimonials from businesses utilizing these forms reveal impactful improvements in product quality and safety assurance driven by efficient testing and documentation processes. Users report that adopting comprehensive testing has not only increased their compliance rates but has also fortified their reputation with consumers.

Moreover, encouraging consistent engagement with the testing and development process cultivates a culture of accountability, ensuring that every packaging decision is informed by rigorous testing results. As such, companies that prioritize effective testing strategies are likely to see a positive impact on overall business success.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify performance oriented packaging testing without leaving Google Drive?

How do I complete performance oriented packaging testing online?

How do I edit performance oriented packaging testing straight from my smartphone?

What is performance oriented packaging testing?

Who is required to file performance oriented packaging testing?

How to fill out performance oriented packaging testing?

What is the purpose of performance oriented packaging testing?

What information must be reported on performance oriented packaging testing?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.