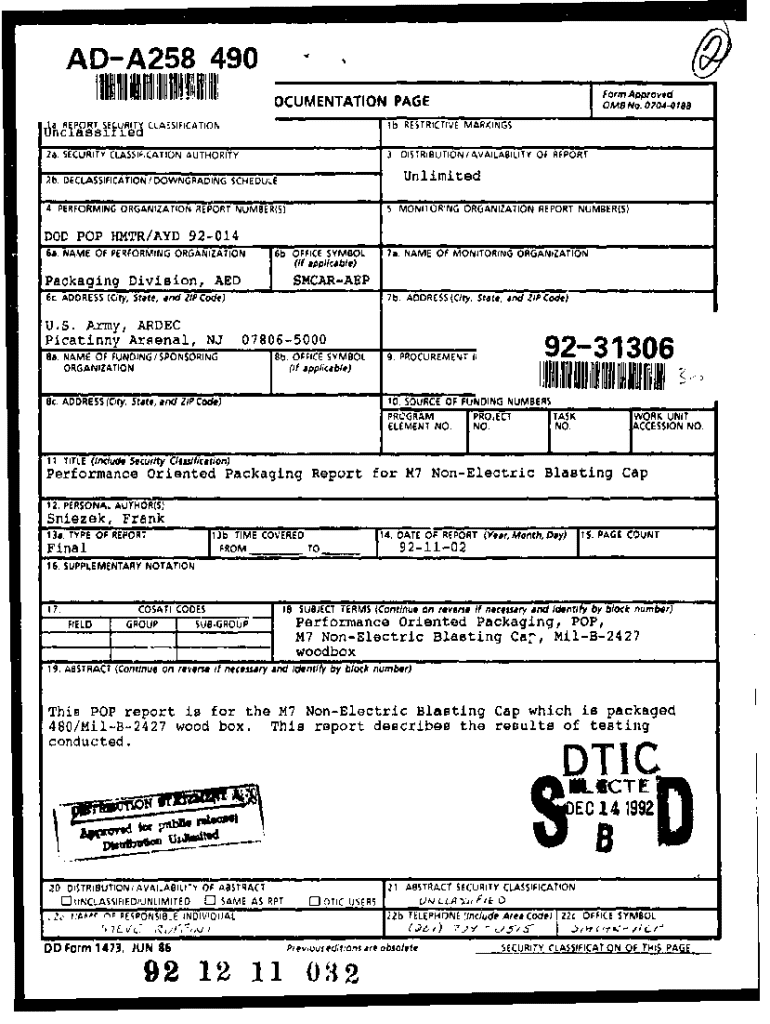

Get the free Performance Oriented Packaging Report for M7 Non-electric Blasting Cap

Get, Create, Make and Sign performance oriented packaging report

How to edit performance oriented packaging report online

Uncompromising security for your PDF editing and eSignature needs

How to fill out performance oriented packaging report

How to fill out performance oriented packaging report

Who needs performance oriented packaging report?

A comprehensive guide to the performance-oriented packaging report form

Understanding performance-oriented packaging (POP)

Performance-oriented packaging (POP) refers to packaging designs and materials that are specifically engineered to meet stringent performance criteria. These criteria often encompass protection, compliance, and sustainability while ensuring that products arrive at their destination in optimal condition. The importance of POP in today's regulatory environment is underscored by increasing consumer awareness and legislation mandating safe and environmentally-friendly packaging. Companies must stay ahead of these regulations and provide packaging that aligns with industry standards and consumer expectations.

Key performance metrics essential to POP include packaging durability, material efficiency, product preservation, and ease of use. These metrics help businesses determine how well their packaging meets projected reliability and safety standards, making it imperative to compile accurate documentation through performance-oriented packaging report forms.

Key components of the performance-oriented packaging report form

The performance-oriented packaging report form is a vital document, encapsulating various aspects of packaging performance and compliance. Understanding the key sections is crucial for effective submission and approval. The main components include:

Each form field holds significance, guiding reviewers to assess compliance efficiently. Material identification may include resins, films, or coatings, while packaging specifications would encompass dimensions and structural integrity data. Testing data should be a thorough evaluation of physical and chemical resistance, moisture barrier properties, and drop test outcomes.

Filling out the performance-oriented packaging report form

Completing the performance-oriented packaging report form can be an intricate process. Following this step-by-step guide can assist in ensuring accuracy and compliance:

Common mistakes often include vague descriptions in material identification or overlooking essential performance criteria in the specifications. Paying attention to detail and double-checking can mitigate these issues.

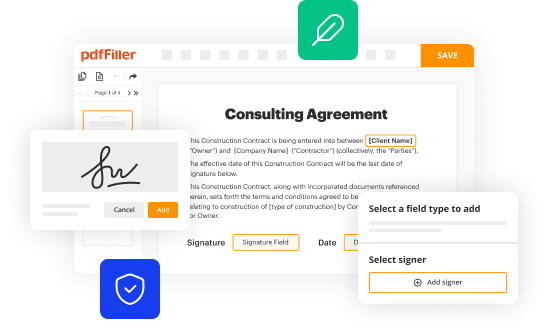

Editing and managing your performance-oriented packaging report form

Editing your performance-oriented packaging report form can be streamlined through pdfFiller's comprehensive editing tools. Users have the ability to make changes directly, add annotations, and organize information seamlessly. Updating the report likely necessitates incorporating new materials or specifications as they evolve. pdfFiller offers features that enhance the editing process by allowing users to manipulate document elements easily, ensuring everything remains accurate and conforms to current standards.

Cloud-based storage provides the benefit of easy access to documents from anywhere. Users can save different versions of their report forms, reducing the risk of data loss and enabling flexibility in managing multiple projects simultaneously.

Collaborating on the report

Collaboration is crucial when handling performance-oriented packaging report forms. pdfFiller allows users to invite team members for reviews and edits directly on the document. This feature fosters a team-oriented approach, ensuring that all input is gathered seamlessly.

Security features within pdfFiller protect sensitive data, a non-negotiable aspect of packaging compliance. The platform is equipped to track changes made during collaboration, maintaining version control and ensuring that team members are always working on the most up-to-date information.

Signing and regulatory compliance

E-signing is an essential component of completing the performance-oriented packaging report form. This process legitimizes the submission and ensures that it meets regulatory compliance with current industry standards. pdfFiller enables users to eSign documents securely with a few simple clicks, making the process quick and efficient.

To eSign your report form using pdfFiller, you simply upload the document, designate the signing fields, and add your electronic signature. Furthermore, compliance checks incorporated within the platform help ensure that users meet necessary requirements before submission.

Interactive tools for enhanced usability

pdfFiller’s interactive features serve to enhance usability significantly. Tools such as packaging calculators can assist users in determining material requirements based on product size, while converters make it easy to switch between document formats. These interactive utilities improve accuracy and reduce potential errors in report submission.

Utilizing these tools supports a tailored document creation experience, allowing users to quickly adjust parameters and refine their packaging submissions according to requirements that pertain to their specific industry.

Common questions and troubleshooting

Users often have questions regarding the performance-oriented packaging report form, particularly on filling out complex sections or troubleshooting technical issues during the editing process. Common concerns might include how to correctly interpret performance metrics or resolve difficulties with uploading documents.

In such instances, reaching out to support for additional assistance can provide clarity and ensure that users navigate the form effectively. pdfFiller provides resources for common queries and a support team ready to assist users in ensuring their submissions are flawless.

Real-world applications and case studies

Understanding real-world applications of the performance-oriented packaging report form helps illuminate its value. For instance, a major beverage company might utilize POP to ensure their product packaging meets all regulatory standards, significantly reducing returns and increasing consumer trust.

Similarly, industries such as pharmaceuticals are increasingly implementing POP strategies to ensure that sensitive products remain intact during distribution. Lessons learned from these case studies often highlight the importance of thorough documentation, testing, and iterative feedback loops in optimizing packaging performance.

Additional considerations and best practices

Staying abreast of future trends in performance-oriented packaging is crucial for compliance and market relevance. Companies should keep a close eye on advancements in sustainable materials and digital innovations that can shape packaging design. Monitoring regulatory changes regularly also aids in ensuring compliance with evolving industry standards.

Resources for ongoing education in packaging compliance, including webinars, industry publications, and workshops, can further equip teams to implement best practices and remain competitive within their sectors.

Feedback and continuous improvement

User feedback on the performance-oriented packaging report form experience contributes significantly to continual enhancement of the pdfFiller platform. Creating an engaging user experience is fundamental; therefore, encouraging individuals and teams to share their thoughts can lead to insightful improvements.

Community engagement also plays a role; users can share best practices and insights, driving the platform's iterative development and ensuring that it meets user needs effectively.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I make changes in performance oriented packaging report?

How do I edit performance oriented packaging report straight from my smartphone?

Can I edit performance oriented packaging report on an iOS device?

What is performance oriented packaging report?

Who is required to file performance oriented packaging report?

How to fill out performance oriented packaging report?

What is the purpose of performance oriented packaging report?

What information must be reported on performance oriented packaging report?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.