Get the free Controlled Joint Detail - ftp dot state tx

Get, Create, Make and Sign controlled joint detail

Editing controlled joint detail online

Uncompromising security for your PDF editing and eSignature needs

How to fill out controlled joint detail

How to fill out controlled joint detail

Who needs controlled joint detail?

A comprehensive guide to filling out the controlled joint detail form

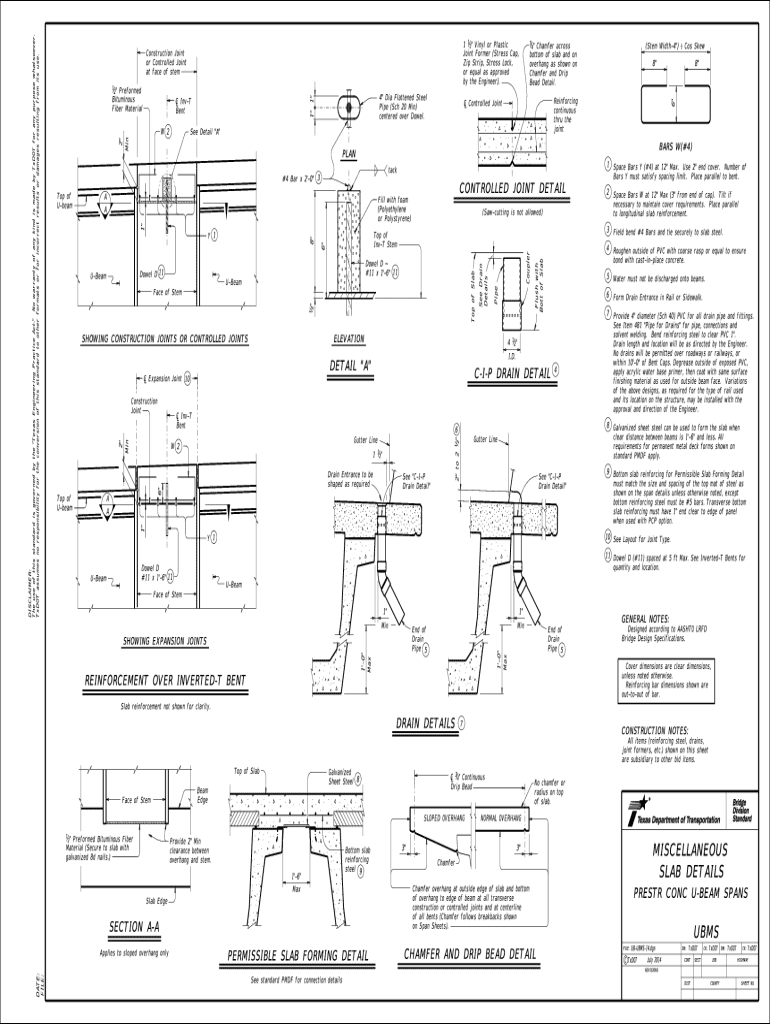

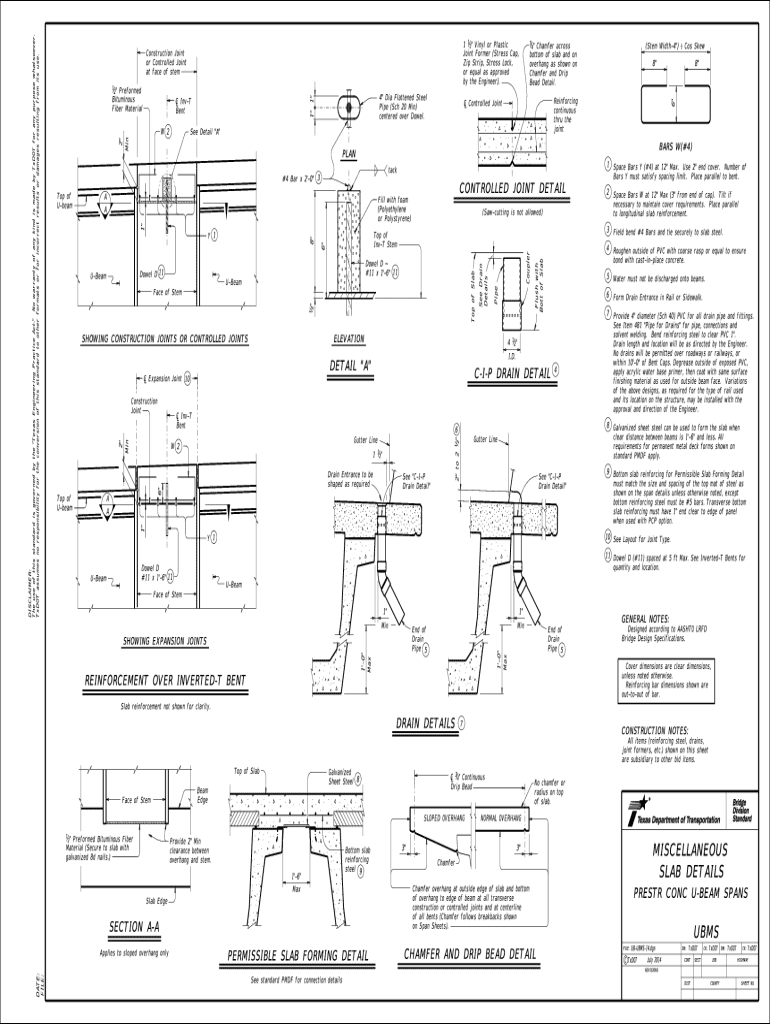

Overview of controlled joint details

A controlled joint detail refers to a designed separation in construction materials, often utilized to manage cracking and stress distribution effectively. By incorporating these joints, engineers and architects ensure that materials can expand and contract without compromising structural integrity. This strategic placement is pivotal in construction design, offering a harmonious balance between aesthetics and functionality.

Controlled joints play a critical role in a variety of construction projects, from pavements and flooring to walls and ceilings. Their importance extends beyond mere aesthetics; they serve as a safeguard against unexpected structural failures due to environmental factors or load stresses. In the absence of these joints, buildings may suffer from unsightly cracks or even severe structural damage.

Types of controlled joint details

Diverse types of controlled joint details cater to various material specifications and project requirements. Understanding the nuances among different joint types is essential for successful construction implementation.

CMU (Concrete masonry unit) joints

CMU joints specifically cater to concrete masonry applications, allowing for flexibility and control in structural integrity. Typically utilized in walls, these joints enable expansion and prevent cracking from thermal cycles.

The advantages of CMU joints include their ability to support high load capacities while providing aesthetic uniformity. Moreover, they can be seamlessly integrated into larger block patterns, enhancing overall visual coherence.

Terrazzo joints

Terrazzo joints require specific design considerations to ensure durability and aesthetic appeal in flooring applications. These joints facilitate proper drainage and allow for natural shifts in material while reducing the risk of joint failure.

Performance standards for terrazzo joints typically focus on maintaining an even surface and preventing moisture intrusion, making them a crucial aspect of flooring design in commercial and residential projects.

Floor and ceiling joint details

Joint details in flooring and ceilings encompass several materials, including sand cushion terrazzo, which requires precise integration into design specs. Each joint type can have unique functional benefits, such as noise reduction or enhanced thermal performance.

It’s essential to choose the joint type based on the specific demands of the project, factoring in the intended use, material compatibility, and environmental conditions.

Factors influencing joint design

Several critical factors influence the design of controlled joints, primarily revolving around material selection and environmental considerations. Ensuring that each element is tailored to the project's needs can significantly impact longevity and performance.

Material selection

Choosing the right materials for controlled joints hinges upon two primary considerations: backing material options and the primary material itself. Backing materials, such as foam or rubber, can provide the necessary resilience to accommodate expansion, while the primary material must be robust enough to support structural loads.

Environmental considerations

Environmental factors like temperature fluctuations and humidity levels can significantly influence the performance of controlled joints. Proper assessment before construction is essential to ensure that the joints can withstand these natural pressures without leading to failure.

Load and stress distribution

Controlled joints are vital in managing load and stress distribution. Engineers use various mechanisms, such as reinforcement bars or flexible sealants, to ensure that any potential cracking is mitigated. This strategic engineering decision keeps structures safe and stable under variable loads.

Interactive tools and resources

Accessing the right tools for creating and managing controlled joint details can streamline the document management process significantly. pdfFiller offers robust resources for individuals and teams looking to enhance their document management experience.

Accessing 3D Warehouse for joint details

3D Warehouse is an expansive repository of joint details that can significantly aid in construction design. Users can browse various joint designs tailored for specific needs.

To download joint details, follow these simple steps:

Utilizing pdfFiller for document management

Using pdfFiller, users can easily edit, sign, and collaborate on the controlled joint detail form. The platform facilitates quick adjustments, fosters collaboration among project teams, and ensures that everyone stays updated on revisions.

How to fill out the controlled joint detail form

Filling out the controlled joint detail form needs precision to ensure all relevant information is accurately recorded. Here is a detailed, step-by-step guide to effectively complete the form.

When filling out the form, accuracy is paramount. Here are tips to ensure your submissions are thorough and reliable:

Quality assurance & control

Maintaining quality assurance and control is essential throughout the process of designing and implementing controlled joints. Compliance with necessary codes and performance standards is vital in guaranteeing the long-term functionality of construction projects.

Documenting compliance includes maintaining records of approvals, inspection reports, and adherence to best practices. This documentation not only protects against potential structural issues but also assures stakeholders of the integrity of the project.

The role of professional oversight cannot be understated. Regular inspections by qualified personnel can ensure that all joint installations are performed according to specified standards, mitigating risks associated with failing joints.

Related products and services

To facilitate the implementation of effective controlled joint details, a variety of related products and services are available. These products often include detailed submittal sheets that outline specifications, compatibility, and application instructions.

For enhanced design competitiveness, consider companion products that align with joint detail applications. Tools that support accurate design calculations, efficiency improvements, and innovative installation methods can provide substantial project benefits.

If you require quotations for specific materials or products, accessing service representatives through formal channels can quickly provide you with necessary pricing and availability information.

Customer service and support

For users encountering issues or needing assistance with controlled joint details, navigating available support channels is crucial. pdfFiller provides robust customer service aimed at fostering efficient and effective experiences for all users.

Common queries related to joint details typically encompass filling out forms, understanding compliance requirements, and finding precise material solutions. Engaging with a multi-disciplinary team can enhance the likelihood of project success, as diverse expertise leads to more informed decision-making.

Advanced techniques in joint design

Emerging advanced techniques in joint design are changing the landscape of construction. Alternative materials, such as high-performance polymers or composite materials, are being explored for their potential benefits.

Understanding the historical context of controlled joint design also reveals how evolving best practices affect current standards. Studying case studies of successful projects that have utilized innovative joint strategies provides invaluable insights for future endeavors.

Industry associations and networking opportunities

Engaging with industry associations provides access to a wealth of resources and networking opportunities. These organizations promote best practices, advocate for standards compliance, and offer educational initiatives that can significantly benefit construction professionals.

Building connections within the construction community facilitates knowledge exchange and collaboration, leading to improved project outcomes and the sharing of innovative solutions. Regular updates on projects and innovations contribute to continual learning in the field.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send controlled joint detail for eSignature?

How do I complete controlled joint detail online?

How do I edit controlled joint detail in Chrome?

What is controlled joint detail?

Who is required to file controlled joint detail?

How to fill out controlled joint detail?

What is the purpose of controlled joint detail?

What information must be reported on controlled joint detail?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.