Get the free Material Safety Data Sheet

Get, Create, Make and Sign material safety data sheet

How to edit material safety data sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material safety data sheet

How to fill out material safety data sheet

Who needs material safety data sheet?

A comprehensive guide to the material safety data sheet form

Understanding material safety data sheets

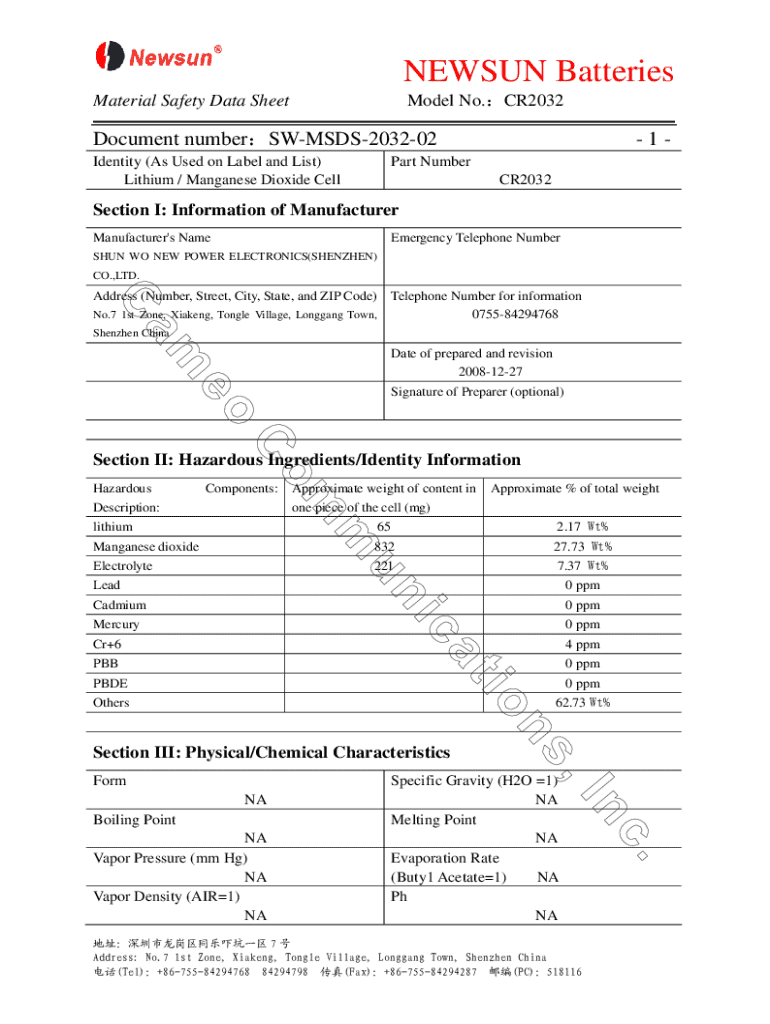

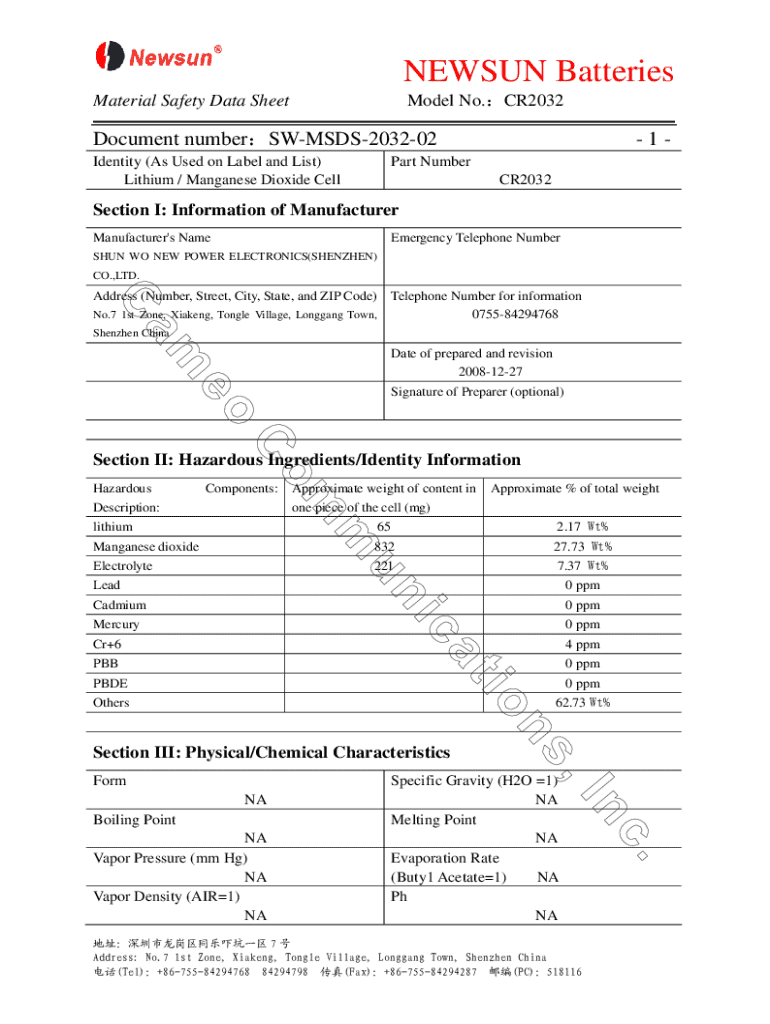

A Material Safety Data Sheet (MSDS) functions as a crucial document that provides detailed information about the properties, hazards, and safe handling of chemical substances. It plays a vital role in communicating risks associated with chemicals in various industries, ensuring that workers are well-informed about potential dangers they may encounter. Knowing how to interpret and utilize an MSDS is essential for health and safety compliance.

The importance of the MSDS extends beyond compliance; it is integral to workplace safety as it informs employees of not only the hazards but also emergency procedures, protective measures, and handling instructions. By promoting a culture of safety within organizations, MSDSs help to prevent accidents and reduce workplace injuries, fostering a safer work environment for all.

MSDSs are also compliant with several regulations. In the United States, the Occupational Safety and Health Administration (OSHA) mandates the use of MSDSs under specific workplace standards. Furthermore, the Globally Harmonized System (GHS) sets an international framework for chemical labeling and hazard communication, streamlining how hazards are communicated across borders.

Key components of an MSDS

A well-structured MSDS contains several key components that are essential for its utility. These components include identification of the substance, hazard identification, composition and ingredients, as well as first aid measures, fire-fighting measures, accidental release measures, and handling and storage guidelines.

Creating your material safety data sheet form

Creating a Material Safety Data Sheet form begins with gathering all necessary information about the chemical being assessed. Start by identifying the chemical name, CAS number, molecular structure, and intended use. Collect data from reliable sources such as supplier documentation, scientific literature, and regulatory compliance systems to ensure all details are accurate and comprehensive.

Using the correct format is essential to compliance. The layout should align with OSHA guidelines or GHS requirements, which often specify a standardized 16-section format. When filling out each section, be meticulous in providing clear and concise information, keeping the language simple yet professional. This clarity is crucial, as it ensures that readers with varying levels of understanding can easily interpret the data.

Common mistakes to avoid include leaving out crucial information or using vague descriptions. Inaccurate data not only violates regulatory requirements but could potentially endanger employees. Therefore, before finalizing the MSDS, implement a check process to ensure every section has been accurately completed.

To maintain compliance with legal requirements, it is vital to stay updated on regulatory changes and to revise your MSDS accordingly. Regularly review the documents to ensure they reflect the most current safety data and adhere to the necessary industry standards.

Editing and customizing your MSDS

Once the initial MSDS is created, continuous editing and updating are necessary to ensure relevance. Utilizing pdfFiller’s features, you can easily edit PDFs to introduce new information, adjust existing data, and maintain compliance with any changes in regulation or chemical use.

Modifying content within your MSDS can be done efficiently in pdfFiller. It allows users to add text, remove obsolete information, and illustrate safety measures more effectively. Additionally, you have the option to incorporate custom labels and safety pictograms to enhance the MSDS’s visual clarity and compliance with GHS signage standards.

Ultimately, ensuring the MSDS is up-to-date entails proactive monitoring of chemical regulations and industry best practices. It’s advisable to designate a health and safety officer to oversee document revisions and communicate these updates to all employees effectively.

Signing and sharing the MSDS

The importance of eSigning your MSDS cannot be overstated. An electronic signature legitimizes the document, ensuring that it has been reviewed and approved by qualified individuals. This step not only solidifies compliance with regulations but also serves as a method to track document changes over time.

Using pdfFiller, eSigning your MSDS is straightforward and user-friendly. Simply navigate to the designated section within your document, choose the eSigning option, and follow the prompts to authenticate the signature. This adds a layer of security and authenticity to the document, enhancing its legal standing.

Sharing the MSDS with your team and stakeholders is crucial. It is best practice to provide easy access to the document through shared platforms like corporate intranets or document management systems. By maintaining transparency and ensuring all team members have easy access to the MSDS, companies can foster a collective responsibility towards safety.

Managing your MSDS documents

Centralizing your MSDS in pdfFiller streamlines the management process by allowing organization-wide access to up-to-date documents while maintaining compliance. By storing all MSDS forms in one cloud-based platform, employees can easily find the information they need, promoting safer work environments and efficient operations.

Interactive tools within pdfFiller enhance the overall document management experience. Features such as search functions for quick reference, tag systems for easy organization, and version control capabilities ensure that every team member is referencing the latest document. This is instrumental in identifying chemical hazards and understanding how to handle materials correctly.

In addition, utilizing collaboration features for team-based projects allows multiple users to work on or access the MSDS simultaneously, enhancing engagement and information sharing. Setting permissions and access controls ensures that sensitive information remains protected while still permitting essential users easy access.

Best practices for MSDS management

Regular review and update procedures should be established to ensure that the MSDS remains accurate and compliant with current regulations. This can be achieved through scheduled audits, appointing a safety officer to oversee updates, and using feedback loops from employees to identify necessary changes.

Training employees on MSDS usage is another key step. Empowering your workforce with knowledge will allow them to take proactive measures when handling chemicals. Conduct routine training sessions that not only cover the existence of the MSDS but emphasize the significance of each section—how to identify risks, safe handling practices, and emergency responses.

Implementing a compliance audit checklist ensures that all relevant regulations are adhered to and can serve as a valuable resource during inspections. By integrating MSDS in safety reporting and incident investigations, organizations can continually learn and adapt their safety measures to prevent future occurrences.

Accessing additional resources

Developing a thorough understanding of Material Safety Data Sheets involves utilizing a variety of resources. Frequently Asked Questions about MSDS can help answer common queries and provide clarity on confusing subjects. Furthermore, linking to relevant regulatory bodies and guidelines will assist in ensuring you're meeting all safety requirements.

Utilizing customer support tools provided by pdfFiller can guide users through the complexities of MSDS management. The interactive help tools help facilitate an understanding of the platform and ensure you can maximize the applications provided.

Understanding the benefits of using pdfFiller for managing MSDS is paramount. Engaging with user testimonials can provide insights into how others in your field effectively utilize the platform, creating a more informed and improved MSDS management process.

Case studies: successful MSDS implementation

Examining real-world examples of effective MSDS usage highlights the importance of diligent implementation. Certain companies have successfully streamlined their chemical management protocol by organizing their MSDS documentation efficiently, resulting in fewer incidents and improved safety ratings.

These case studies illustrate how proactive training and updates can significantly enhance workplace safety practices. Lessons from industry leaders showcase that adopting innovative document management solutions, like those offered through pdfFiller, can revolutionize how organizations maintain safety compliance with MSDS.

By embracing these successful strategies, other organizations can also enhance their workplace safety culture and compliance with materials handling.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute material safety data sheet online?

How do I fill out the material safety data sheet form on my smartphone?

Can I edit material safety data sheet on an Android device?

What is material safety data sheet?

Who is required to file material safety data sheet?

How to fill out material safety data sheet?

What is the purpose of material safety data sheet?

What information must be reported on material safety data sheet?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.