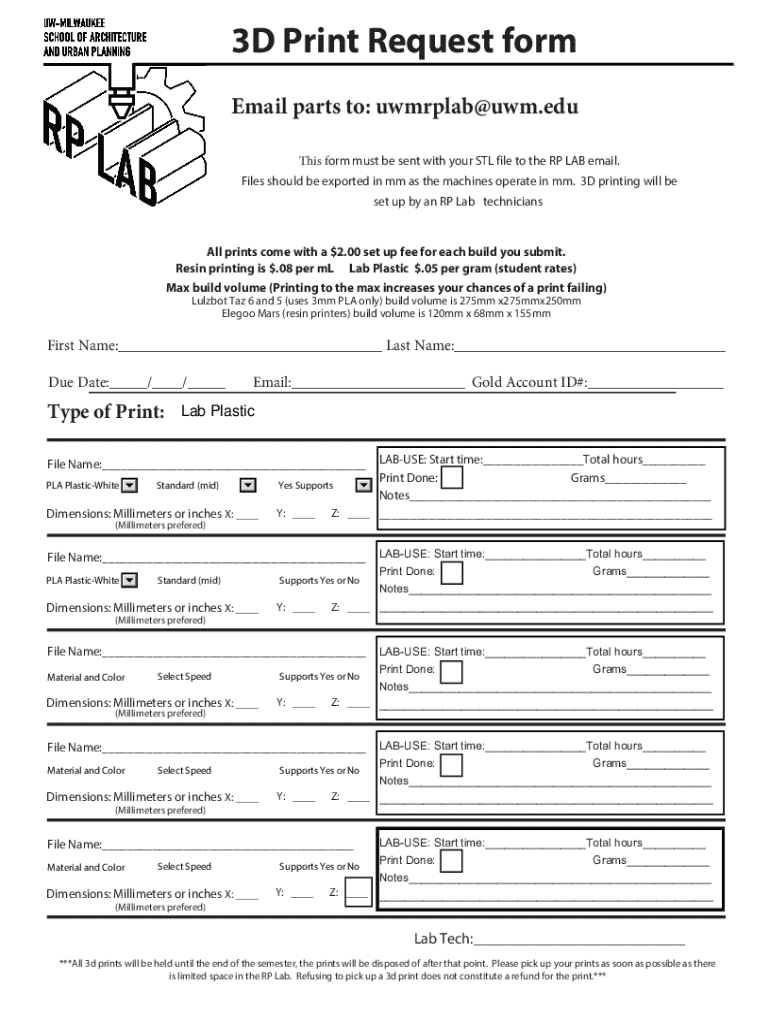

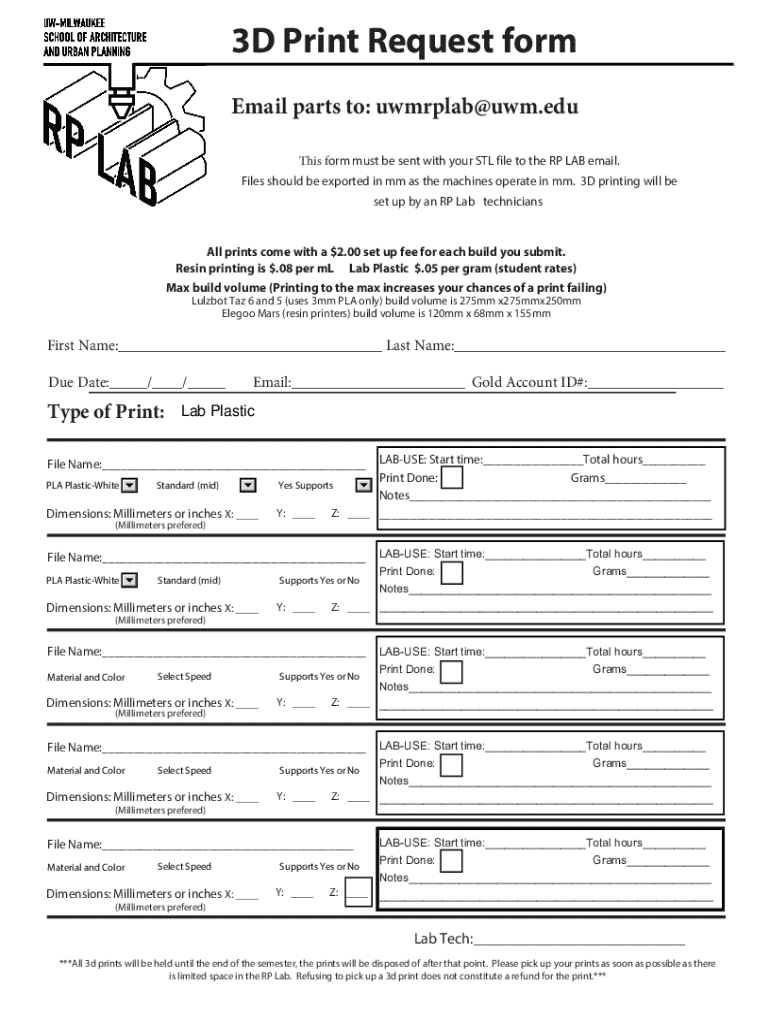

Get the free 3d Print Request Form

Get, Create, Make and Sign 3d print request form

Editing 3d print request form online

Uncompromising security for your PDF editing and eSignature needs

How to fill out 3d print request form

How to fill out 3d print request form

Who needs 3d print request form?

3D Print Request Form: A Comprehensive How-to Guide

Understanding 3D Printing

3D printing, or additive manufacturing, is a transformative technology that allows for the creation of three-dimensional objects from digital files. It works by layering materials, typically plastic, metal, or resin, until the final product is formed. Each layer is precisely added based on the specifications from the 3D model, making this method both innovative and efficient.

Several different technologies exist within the realm of 3D printing. Fused Deposition Modeling (FDM) is the most common, utilizing thermoplastic filaments. Stereolithography (SLA) employs lasers to cure liquid resin into hardened plastic, whereas Selective Laser Sintering (SLS) utilizes lasers to fuse powdered materials together. Each method carries its unique benefits and applications across numerous industries.

Applications of 3D printing are incredibly diverse, impacting sectors such as healthcare, aerospace, automotive, fashion, and education. For instance, in healthcare, it is used to create prosthetics tailored to individual patients, while in automotive, it enables rapid prototyping for car parts. The versatility of 3D printing continues to expand, illustrating its importance in modern manufacturing and design.

The importance of a 3D Print Request Form

A 3D print request form serves as a vital tool in managing print requests efficiently. It centralizes requests from multiple users, which streamlines communication and reduces the likelihood of missed information. For teams or organizations that regularly utilize 3D printing, having a dedicated form can significantly improve productivity and oversight.

Moreover, a request form ensures accuracy and detail in submissions. Without such a form, misunderstandings can lead to errors, wasted materials, and increased costs. Common mistakes often arise when details are either omitted or inaccurately communicated, which can compromise the quality of the final print. A structured request form mitigates these risks.

Preparing your 3D model

Before submitting a request for 3D printing, preparing your 3D model is crucial. Start by conceptualizing your project; consider the functionality and aesthetics of your model. Engage with design brainstorming methods that stimulate creativity and focus on viable project outcomes.

When designing your model, using the right software is key. Popular recommendations include Blender for intricate designs, Tinkercad for beginners, and Fusion 360 for engineering applications. Each software offers various features suited to different levels of expertise and requirements.

Essential design considerations must also be addressed. Pay attention to dimensions and scale to ensure the model fits your intended application. Your model should adhere to manifold design principles, meaning there should be no gaps or non-manifold edges. Lastly, choosing the appropriate color and filament types can play a significant role in the appearance and function of the final print.

Submitting your 3D print request

The submission process for a 3D print request is straightforward but requires careful attention to detail. Begin by accessing the designated 3D print request form on your facility’s website or portal. If the facility allows online submissions, ensure you have a reliable internet connection.

Next, fill out the required information thoroughly. This typically includes details like your name, contact information, project name, and specific requirements for the print. Once you’ve filled out the form, upload your 3D model file in the required format.

After uploading, review all submission details to confirm accuracy. Check for typos, confirm specifications match your design, and ensure you’ve included any necessary notes about the printing process. Finally, finalize your submission and submit the form.

For a successful submission, consider these tips: stick to file format requirements, understand printer policies, and familiarize yourself with slicer settings. Common file formats include STL and OBJ, which are widely accepted in the 3D printing community.

Cost and fees for 3D printing

Understanding the cost involved in 3D printing is essential for planning your project budget. Fees for 3D printing typically encompass material costs, labor, and sometimes additional service fees depending on the complexity of the print job. The material chosen significantly impacts the total cost, as different filaments or resins vary in price.

For instance, a standard thermoplastic filament like PLA may cost around $20 per kilogram, whereas specialty materials such as nylons or composites could reach upwards of $100 per kilogram. Labor costs may also vary based on the level of expertise required for your print job. Organizations might benefit from discounts or grants, especially educational institutions that often have dedicated budgets for 3D printing resources.

What to expect after submission

Following the submission of your 3D print request, expect a review process that typically spans a specified timeline, depending on the service provider. This period allows the printing team to assess the model, verify requirements, and troubleshoot any potential issues before printing.

Communication with the printing facility is key during this stage. Keep an eye on notifications for feedback or requests for revisions. If changes are needed, the facility will reach out to clarify requirements. Understanding approval and denial notifications is equally important, as it informs you whether your print job is proceeding as planned.

Managing your 3D printing project

Effective management of your 3D printing project requires collaboration with your team throughout the printing process. Regular meetings can help keep everyone aligned on the project goals and timelines. Use tools like project management software or shared documents to track progress and document any changes made during the print job.

Tracking the progress of your request is essential to ensure timelines are met. Many printing facilities offer tracking systems where you can see the status of your print job in real-time. Furthermore, efficient communication can greatly aid in resolving any issues that arise, leading to smoother project execution.

Troubleshooting common issues

As with any process, challenges may arise during your 3D printing journey. Familiarize yourself with frequently asked questions to minimize frustration. A common issue is the rejection of submitted models. If your model is not accepted, reviewing the submission guidelines closely can help identify discrepancies or errors.

Additionally, if modifications are necessary, contact the printing facility directly to understand their policies for adjusting submitted requests. Knowing when and how to reach out for support is essential for overcoming hurdles and ensuring that your project stays on track.

Developing your skills in 3D printing

To excel in the realm of 3D printing, continuous learning is key. Numerous resources are available, including online courses, webinars, and workshops tailored for beginners to advanced practitioners. Organizations often offer training sessions, ensuring that team members are well-equipped with the skills needed for effective modeling and printing.

Engagement with the 3D printing community can provide networking opportunities and insights into industry trends. Joining forums or local maker spaces can connect you with like-minded individuals, and accessing the latest technological advancements in 3D printing can keep your skills sharp and your projects relevant.

Leveraging pdfFiller for your 3D print requests

pdfFiller enhances your 3D print request experience through its easy-to-use platform that streamlines document management. Users can edit and sign request forms seamlessly, collaborate with team members in real-time, and access documents from anywhere, ensuring flexibility and efficiency in the submission process.

Utilizing pdfFiller’s features can elevate your document workflow. The collaboration tools allow multiple stakeholders to work together, making the process of submitting and revising 3D print requests a group effort that saves time and minimizes errors. Moreover, the cloud-based access means you can manage your printing projects on the go.

Best practices for future projects

Employing best practices when working with 3D printing projects lays the groundwork for success. Keeping a meticulous prototype record allows you to learn from past experiences and refine your designs. Iterating on your designs based on feedback can further enhance the quality and function of your future projects.

Staying current with 3D printing innovations—such as new materials, methodologies, and software updates—ensures that you remain competitive and informed. Engaging with industry publications and communities that focus on 3D printing will fill your knowledge bank with insights valuable for your ongoing work.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I sign the 3d print request form electronically in Chrome?

Can I create an eSignature for the 3d print request form in Gmail?

How do I fill out the 3d print request form form on my smartphone?

What is 3d print request form?

Who is required to file 3d print request form?

How to fill out 3d print request form?

What is the purpose of 3d print request form?

What information must be reported on 3d print request form?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.