Get the free Material Safety Data Sheet

Get, Create, Make and Sign material safety data sheet

How to edit material safety data sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material safety data sheet

How to fill out material safety data sheet

Who needs material safety data sheet?

Material Safety Data Sheet Form: A How-to Guide Long-Read

Understanding the Material Safety Data Sheet (MSDS)

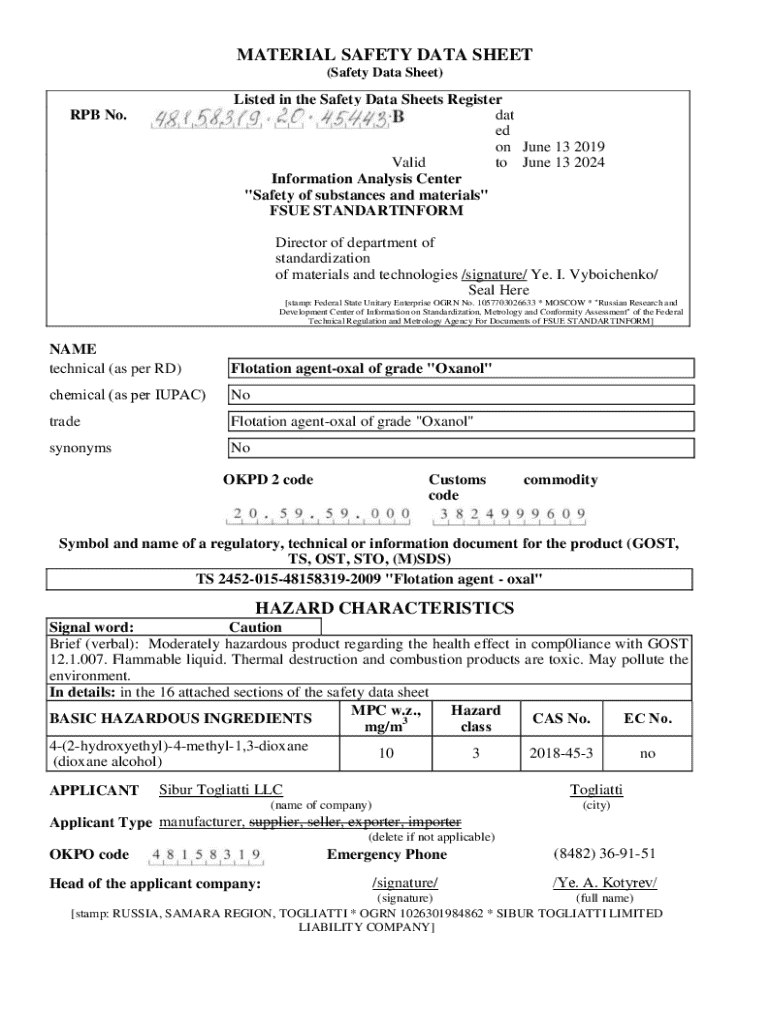

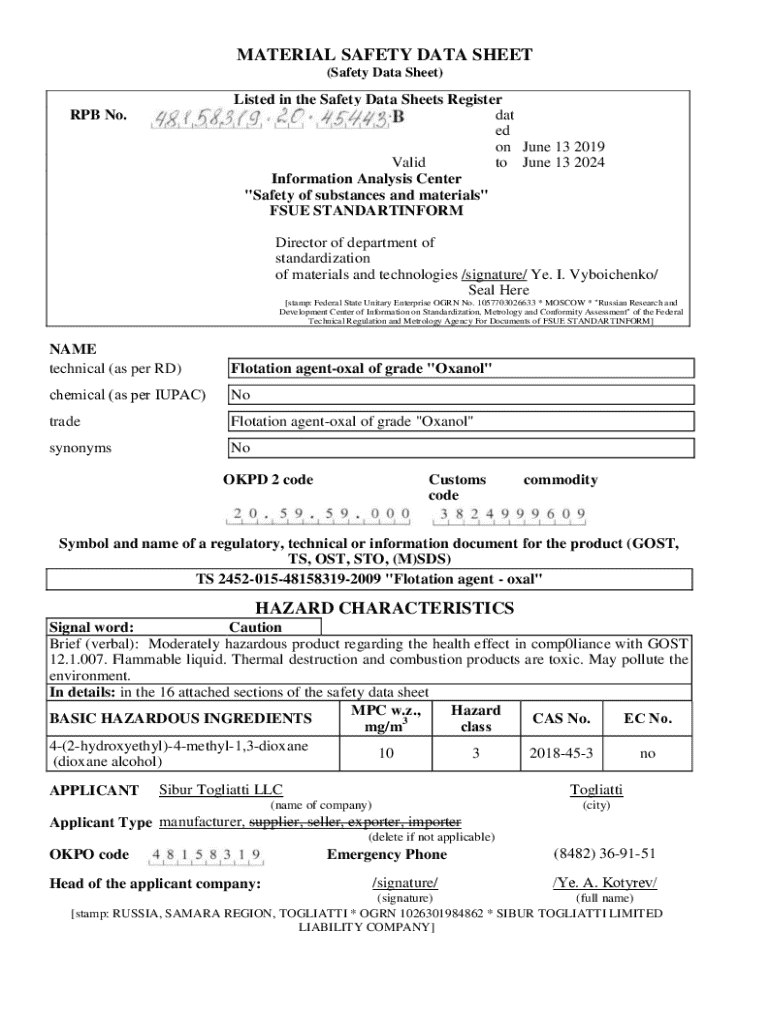

A Material Safety Data Sheet (MSDS) is a crucial document used to provide comprehensive information about a specific chemical substance. It serves as a primary resource in the safe handling, storage, and disposal of hazardous materials. The importance of an MSDS cannot be understated, as it ensures that individuals who come into contact with hazardous substances are aware of the potential risks, necessary precautions, and emergency measures.

Key components of an MSDS include product identification, hazard warnings, safe handling instructions, and emergency response measures. This holistic approach equips workers and emergency personnel with information that can prevent accidents and ensure safety in various work environments.

Legal and regulatory framework

The Occupational Safety and Health Administration (OSHA) has established regulations surrounding the use of MSDS to ensure workplace safety. Under OSHA's Hazard Communication Standard, employers are required to provide employees with access to MSDS forms for all hazardous substances they may encounter. Non-compliance can lead to legal repercussions and unsafe working conditions, emphasizing the necessity of adhering to these regulations.

In addition to OSHA, several other local and international guidelines, such as the Globally Harmonized System (GHS), influence the structure and content of MSDS. Understanding these regulations is vital for businesses to maintain a safe and compliant workplace.

Structure of the Material Safety Data Sheet

An MSDS follows a standardized format to ensure clarity and ease of use. Each sheet typically contains several distinct sections, which play a crucial role in conveying important safety information.

Globally Harmonized System (GHS) compliance

The GHS standardizes the classification and labeling of chemicals worldwide, aiming to enhance safety and minimize chemical-related incidents. Compliance with GHS requires MSDS formats to adhere to specific content requirements and labeling conventions, including the use of standardized GHS symbols. These symbols effectively communicate hazards visually, making it easier for users to understand and act accordingly.

The transition to GHS-compliant MSDS can significantly improve safety communication across industries, facilitating better understanding among workers and reducing the likelihood of accidents related to chemical exposure.

Creating and managing an MSDS form

Filling out a Material Safety Data Sheet requires careful attention to detail and a thorough understanding of the chemical in question. The first step in creating an MSDS is to gather accurate information, including specific data on the chemical's properties, potential hazards, and handling guidelines. It’s essential to consult reliable sources, such as chemical manufacturers and regulatory agencies.

Once the needed information is collected, you can begin filling out the MSDS form, ensuring that each section is completed clearly and accurately. Here are step-by-step instructions to guide you through the process:

Using tools like pdfFiller can enhance your experience with creating and managing MSDS forms. This platform allows you to modify existing templates, making it simple to add your specific information while complying with current guidelines.

Editing and customizing your MSDS

pdfFiller offers interactive features that allow you to customize existing MSDS templates, ensuring that your documents remain accurate and up-to-date. With its user-friendly interface, you can make amendments efficiently, reducing the time spent on paperwork. You can effortlessly integrate company-specific protocols and local regulations into your MSDS, making it a precise reflection of your operational practices.

Signing and sharing your MSDS form can also be completed within pdfFiller. The platform accommodates eSigning options that facilitate collaboration among team members, ensuring that everyone involved has access to the latest version of the document.

Best practices for using material safety data sheets

To ensure maximum effectiveness, it's essential that MSDS forms are easily accessible and properly stored. Digital storage solutions, such as cloud-based systems, can aid in maintaining an organized repository of MSDS forms. These solutions not only provide safety and security but also streamline the retrieval of critical information when needed.

A robust training program is crucial to ensure that all employees understand the relevance and importance of MSDS documentation. Educating staff on how to access, interpret, and utilize these sheets fosters a culture of safety and compliance. Regular training sessions should aim to make the information engaging and directly applicable to their daily tasks.

Clear communication regarding safety practices is imperative for workplace safety. Encourage open dialogues about safety, where employees feel comfortable discussing any concerns related to hazardous materials.

Frequently asked questions about material safety data sheets

Many individuals have questions regarding the management and maintenance of MSDS forms. One common query is, 'How often should MSDS forms be updated?' The general practice is to review and update these documents whenever there is a change in chemical formulation, significant new safety information, or at least once every three years to ensure compliance with current regulations.

Another common question is, 'Who is responsible for maintaining MSDS in a workplace?' Typically, safety officers or designated employees within the organization are responsible; however, all employees should be encouraged to report any discrepancies or concerns regarding MSDS forms.

Resources for additional support

For help with MSDS-related inquiries, pdfFiller’s customer support is available to assist users. They provide resources and advice on utilizing the platform effectively, particularly regarding document management and compliance.

Interactive tools for document management

Within the pdfFiller platform, users can find numerous templates for Material Safety Data Sheets. These pre-made templates simplify the process of creating an MSDS, ensuring that all necessary components are included. Utilizing these resources can drastically reduce preparation time and improve accuracy.

Advanced features within pdfFiller can further streamline document management processes. For instance, automatic reminders for MSDS updates can enhance compliance and maintain safety. The platform allows for collective brainstorming on safety measures, improving overall workplace culture around safety practices.

Compliance and safety data sheet management

National and international compliance requirements for MSDS vary by region, and understanding these differences is essential for multinational operations. Regulations such as REACH in the EU and the Chemical Hazard Communication Standard in the United States outline specific obligations for employers regarding MSDS.

Aligning your MSDS with these compliance standards is critical for ensuring the safety of your workforce and reducing liability. An accurate MSDS reflects a commitment to health and safety, fostering an environment where employees feel safe and valued.

Moreover, an effective MSDS not only protects individual employees but also significantly contributes to overall workplace safety. Case studies illustrate businesses that faced severe penalties and incidents due to inadequate safety documentation, reinforcing the need for comprehensive training and adherence.

Industry-specific considerations

Different sectors have unique MSDS needs based on the materials they handle. For instance, chemical manufacturing industries may require detailed hazard identification sections due to the nature of their work. Conversely, offices using less hazardous materials might simplify their MSDS documentation.

Moreover, MSDS documentation plays a significant role in environmental safety compliance. Ensuring proper disposal methods and reporting requirements are met is integral to reducing environmental impact.

Future trends in material safety data sheets

As technology continues to evolve, so too will the approach to creating and managing MSDS forms. With the integration of artificial intelligence and machine learning, the creation process may become more intuitive, allowing for real-time data analysis and suggestions for updates based on changes in regulations.

Digital platforms like pdfFiller are at the forefront of this evolution, enhancing the user experience by simplifying the document management process. Future trends expect to see further emphasis on mobile accessibility and interactive features, making it increasingly easier for users to engage with safety data, ensuring that workplace safety becomes a more prominent priority.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my material safety data sheet directly from Gmail?

How can I send material safety data sheet to be eSigned by others?

Can I create an electronic signature for signing my material safety data sheet in Gmail?

What is material safety data sheet?

Who is required to file material safety data sheet?

How to fill out material safety data sheet?

What is the purpose of material safety data sheet?

What information must be reported on material safety data sheet?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.