Get the free Material Safety Data Sheet

Get, Create, Make and Sign material safety data sheet

How to edit material safety data sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material safety data sheet

How to fill out material safety data sheet

Who needs material safety data sheet?

Understanding and Utilizing the Material Safety Data Sheet Form

Understanding Material Safety Data Sheets (MSDS)

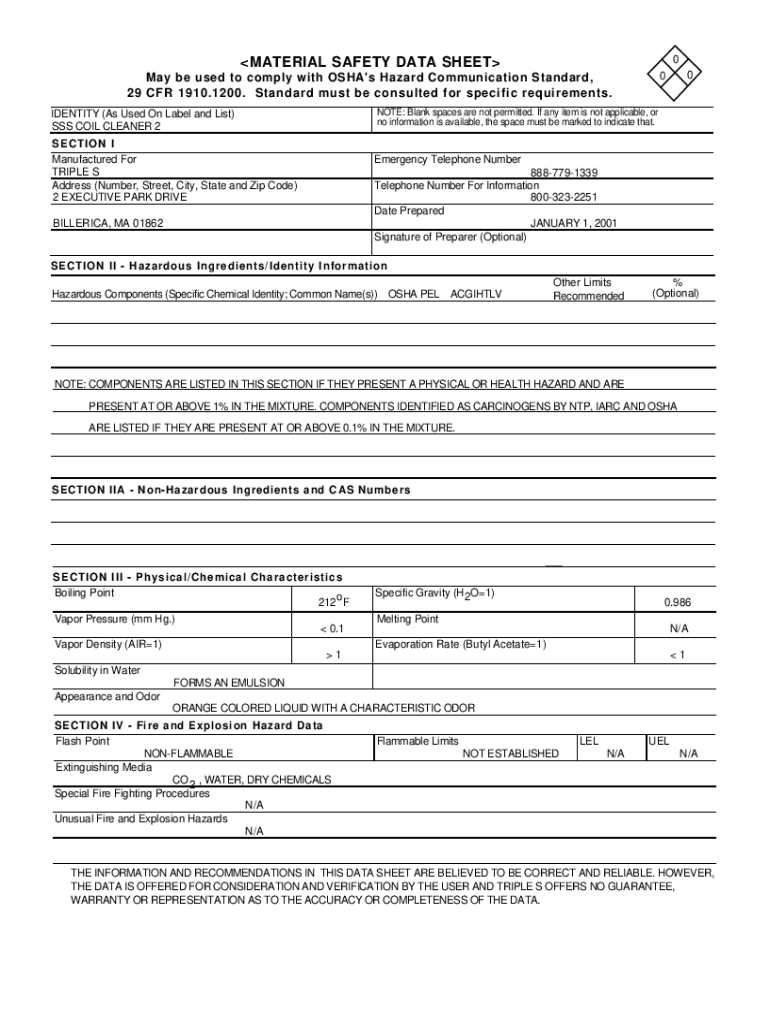

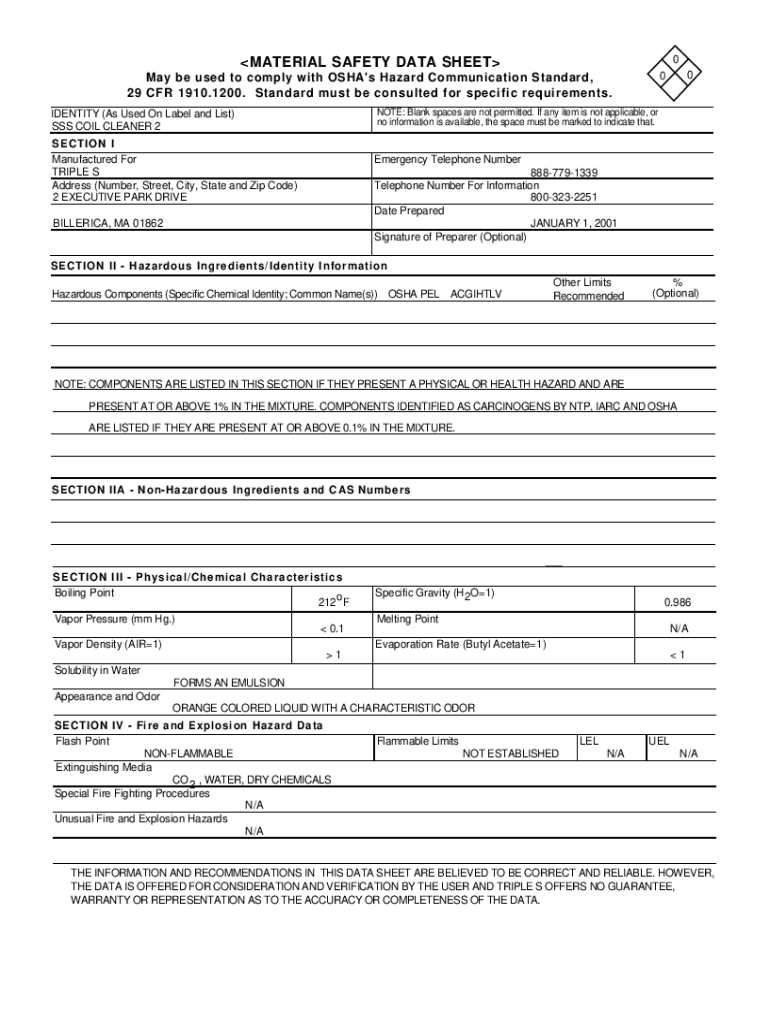

A Material Safety Data Sheet (MSDS) is a vital document that provides comprehensive information about a specific chemical substance. It details the properties of the chemical, its hazards, handling guidelines, and safety measures for use. The primary purpose of the MSDS is to ensure that those who will be handling, storing, or coming into contact with the substance are fully informed of its risks and how to mitigate them.

Safety in the workplace is largely dependent on access to accurate and up-to-date information. MSDS documents play a crucial role in this, serving as a primary resource for employee training and safety protocol development. For many industries, providing access to MSDS is not just beneficial but legally required, facilitating a culture of safety and compliance.

Structure and format of an MSDS

The structure of an MSDS is standardized to ensure clarity and readability. An MSDS typically contains several key sections, each dedicated to specific aspects of the hazardous material. These include Identification, Hazard Identification, and Composition/Information on Ingredients—each providing essential information for safe handling. The detailed breakdown enables users to quickly navigate to the relevant information needed for safe practices.

Following the completion of the key sections, an MSDS generally covers important measures for First-Aid, Fire-Fighting, and Accidental Release. Additionally, it informs on Handling and Storage, Exposure Controls and Personal Protection, Physical and Chemical Properties, Stability and Reactivity, and Toxicological Information. Visual guidelines for the layout help ensure users can find the information efficiently and understand it clearly.

The Globally Harmonized System (GHS) and MSDS

The Globally Harmonized System (GHS) aims to standardize the classification and labeling of chemicals worldwide, enhancing safety through consistent communication of hazards. The GHS framework has been integrated into MSDS documentation to improve clarity, understanding, and compliance across international borders. This standardization helps businesses understand risks associated with their chemical products, thus promoting a safer work environment.

GHS incorporates the use of standardized symbols or pictograms that convey essential information about the hazards. For example, a flame symbol indicates flammability, while an exclamation mark warns of general hazards. This visual approach allows for quick recognition of potential dangers, ensuring that workers can immediately identify critical safety information.

Authoring a Material Safety Data Sheet

Creating a Material Safety Data Sheet requires careful planning and accuracy. It is essential to gather reliable data on the chemical, including its physical and chemical properties, toxicological information, and first-aid measures. Collaborating with safety and health professionals is vital to ensure the document meets all regulatory compliance and effectively communicates hazards.

Utilizing software tools for MSDS creation can streamline the process. pdfFiller offers advanced features that allow users to draft, edit, and finalize MSDS documents efficiently. With its collaboration capabilities, teams can work together in real-time, ensuring that every detail is accurate and up to date. Leveraging such digital solutions minimizes errors and enhances the overall efficiency of MSDS management.

Filling out the Material Safety Data Sheet form

Completing a Material Safety Data Sheet form necessitates attention to detail and accuracy. It begins with gathering all required information about the chemical. Next, you’ll use interactive tools available in pdfFiller to fill in each section of the MSDS, ensuring clarity and compliance with current safety standards. Ensuring that the details are correct and comprehensive is essential to uphold safety and regulatory standards.

Common mistakes often occur during this process, such as neglecting to update information or providing incomplete hazard details. By meticulously reviewing the information and cross-checking with current regulations, users can avoid pitfalls that can lead to compliance issues or safety risks.

Managing your MSDS collection

Once you have created your MSDS documents, effective management of the collection is crucial. Organizing these files based on chemicals, departments, or risk levels can enhance accessibility for employees. Additionally, maintaining compliance with updated regulations involves regular reviews and updates of existing MSDS documents, which is vital for workplace safety.

pdfFiller provides powerful document management capabilities, such as version control and document tracking. This ensures that you can easily manage multiple versions of MSDS files, making updates straightforward. With eSigning and sharing features, organizations can circulate new or updated sheets quickly, ensuring all team members have access to the most accurate information.

Training and resources for safe use of chemicals

Training employees on the importance of Material Safety Data Sheets is paramount in fostering a safe working environment. Regularly scheduled training sessions can ensure that workers are familiar with the MSDS’s structure and content, enabling them to quickly locate critical safety information and follow proper safety protocols.

Creating a centralized repository for MSDS documents can further support employee training and access to information. pdfFiller's cloud-based platform simplifies the management of these documents, ensuring employees can reference them whenever needed. Additionally, providing resources and tools for chemical safety management can enhance overall workplace safety.

Frequently asked questions (FAQs) about MSDS

Understanding the nuances of the Material Safety Data Sheet is essential for compliance and safety. Common queries arise, such as what sections should be included in a typical MSDS, or how frequently they should be updated. Generally, an MSDS includes identification, hazard identification, composition, and handling instructions, among other important sections. Updates should occur whenever there is a significant change in the chemical's status or regulations governing its use.

Responsibility for creating and maintaining MSDS may vary but generally falls under the purview of chemical manufacturers or employers. Different regions may have specific regulations that govern MSDS requirements, necessitating adherence to local laws to ensure compliance and safety in the workplace.

Advanced features of pdfFiller for MSDS management

pdfFiller offers advanced features that cater to the intricate needs of MSDS management. Its interactive tools allow users to create customized MSDS documents from templates or design them from scratch, ensuring precise communication of safety information. Enhanced search capabilities mean users can efficiently access necessary documents, streamlining the workflow and ensuring timely updates.

Furthermore, user roles and permissions can be set within pdfFiller, ensuring that only authorized personnel can edit or view sensitive information. This feature helps maintain security and integrity while promoting efficient collaboration across teams in safety-critical environments.

Expert insights on MSDS compliance and best practices

Gaining insights from compliance experts can illuminate best practices in MSDS management. Regular consultations with safety professionals can help organizations stay aligned with industry trends and regulatory changes impacting MSDS requirements. Experts often stress the importance of effective communication of safety information and ensuring easy access to the latest MSDS for employees.

Staying proactive rather than reactive can significantly enhance safety culture within an organization. Following best practices, such as conducting regular audits of MSDS documents and employee training, can foster an environment where safety is prioritized. These steps not only protect employees but also ensure compliance with evolving regulations.

Case studies and success stories

Examining organizations that have effectively implemented MSDS solutions reveals valuable lessons learned. Successful case studies often highlight strategies such as comprehensive training programs and centralized MSDS repositories that resulted in enhanced workplace safety and compliance. Conversely, failures in MSDS management can serve as cautionary tales, showing the costs associated with neglecting safety protocols.

Many companies that transitioned to pdfFiller found substantial improvements in the management of their MSDS processes. They reported increased efficiency, better team collaboration, and improved compliance tracking. Such transformations often lead to a noticeable reduction in incidents and a stronger safety culture.

Tools for finding the right MSDS templates

Finding suitable MSDS templates is crucial for organizations looking to maintain compliance and ensure the safety of their workforce. pdfFiller’s extensive template library provides a wide range of MSDS formats that can be customized to meet specific needs. This flexibility allows organizations to adapt templates to suit various chemicals and regulatory requirements, thereby enhancing their safety documentation.

When utilizing templates, organizations should focus on best practices in design and usage. Customizing templates should not only include chemical-specific information but also align with industry standards and guidelines. This approach ensures clarity and precision, making it easier for employees to follow the information laid out in each MSDS.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send material safety data sheet for eSignature?

How do I fill out material safety data sheet using my mobile device?

Can I edit material safety data sheet on an Android device?

What is material safety data sheet?

Who is required to file material safety data sheet?

How to fill out material safety data sheet?

What is the purpose of material safety data sheet?

What information must be reported on material safety data sheet?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.