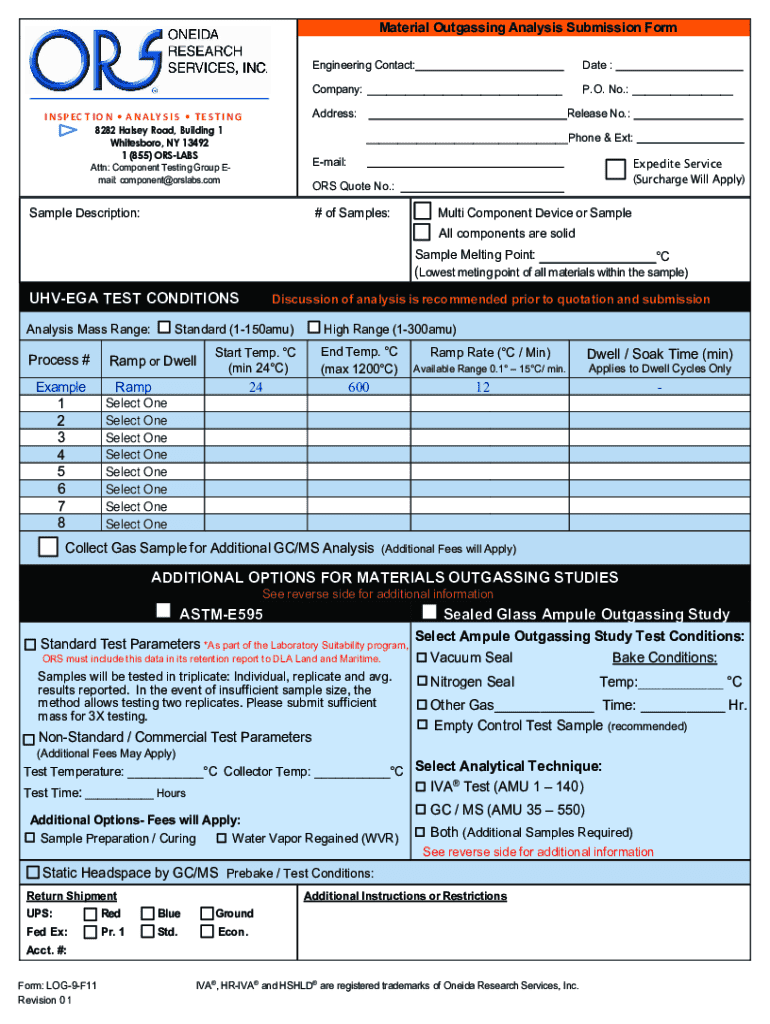

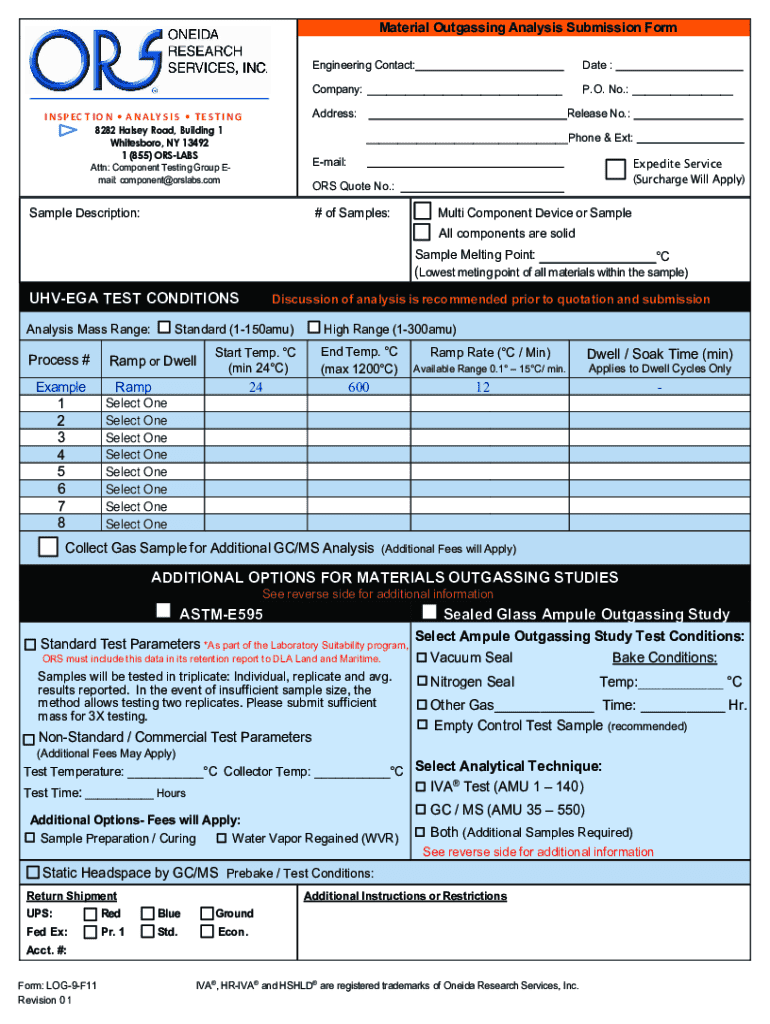

Get the free Material Outgassing Analysis Submission Form

Get, Create, Make and Sign material outgassing analysis submission

How to edit material outgassing analysis submission online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material outgassing analysis submission

How to fill out material outgassing analysis submission

Who needs material outgassing analysis submission?

Material Outgassing Analysis Submission Form: A Comprehensive Guide

Understanding material outgassing

Material outgassing refers to the release of gas that was previously absorbed, adsorbed, or trapped within a material. This phenomenon is particularly significant in high-stakes industries such as aerospace, electronics, and healthcare, where even minor gaseous emissions can lead to significant risks, including contamination, product failure, or safety hazards.

Common materials exhibiting outgassing properties include polymers, adhesives, and certain metals, especially under specific environmental conditions such as high temperatures or vacuum states. Understanding the levels and types of outgassing can be critical for product integrity and operational safety.

Outgassing testing methods

Outgassing analysis employs various testing methods to quantify gas release and assist in material selection. Among the most popular methods are Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA), and Vacuum Stability Analysis. These techniques assess the thermal properties, mass change, and stability of materials under controlled conditions.

It’s essential to recognize that multiple factors influence the outcomes of these tests, including the material composition—such as polymer additives—and environmental conditions during testing, like vacuum levels and thermal gradients.

Material outgassing analysis submission process

To conduct a material outgassing analysis, submitting your material for testing is essential. Here’s a straightforward guide to ensure a smooth submission process.

Interactive tools and resources

Utilizing the submission portal at pdfFiller enhances your experience significantly. Users can navigate through the user-friendly interface, making form submissions quick and intuitive. Moreover, pdfFiller allows you to track the status of your submission post-analysis, ensuring you are always updated.

Once your analysis is completed, accessing in-depth analysis reports through the portal provides valuable insights. Understanding these results is crucial for deciding on material selection moving forward. These reports will typically outline gas release rates, chemical compositions, and any observed anomalies.

Best practices for material selection and testing

When considering materials for applications sensitive to outgassing, selecting low-outgassing materials is paramount. Materials with certain polymer structures and additive compositions are known to mitigate outgassing effects. Consulting industry-specific recommendations can be beneficial in identifying suitable materials.

Another best practice is to conduct regular outgassing assessments. This not only ensures compliance with regulatory standards but also sustains product integrity over time. Frequent evaluations can help catch issues before they escalate, preserving safety and product efficacy.

Common applications of outgassing testing

The significance of outgassing testing spans across various industries. In aerospace and automotive manufacturing, materials must withstand extreme environments, making outgassing analyses essential for safety and performance. Similarly, in electronics, materials with high outgassing can lead to circuit failures.

Medical device production also necessitates rigorous outgassing tests, as any gaseous emissions can compromise sterilization and efficacy. Several industries emphasize the need for rigorous testing, and real-world case studies exemplify how outgassing testing has led to critical corrections, thereby enhancing safety and performance.

Troubleshooting and sample results analysis

Analyzing outgassing test results can reveal common issues such as elevated outgassing levels. These results can point to material defects or unsuitable additive selections that may have contributed to excessive emissions. Understanding these implications is crucial for addressing potential material failure.

Key metrics from test results typically include total emitted gas volumes and specific chemical identities. Readers should familiarize themselves with what these numbers signify, as they directly correlate to material quality and compliance with safety standards.

Contact and support for queries

For any questions regarding the submission of your material outgassing analysis submission form, reaching out to the technical support team at pdfFiller is advised. They can be contacted via direct email or through the integrated support functionality within the platform.

A quick FAQ section is also available, designed to assist users in resolving common queries. If you have feedback on improving the submission experience, pdfFiller welcomes input, ensuring they continually enhance their user interface and processes.

Policies related to material testing and submission

To protect your interests, understanding the terms and conditions associated with material testing services is fundamental. pdfFiller prioritizes data privacy, assuring clients that any information shared remains confidential. They adhere strictly to guidelines that govern material analysis, ensuring your intellectual property and data are safeguarded throughout the testing process.

Additionally, familiarizing yourself with the policies governing your submissions, including timelines, potential fees, and non-disclosure guarantees, can foster a positive user experience.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my material outgassing analysis submission in Gmail?

How do I edit material outgassing analysis submission in Chrome?

Can I sign the material outgassing analysis submission electronically in Chrome?

What is material outgassing analysis submission?

Who is required to file material outgassing analysis submission?

How to fill out material outgassing analysis submission?

What is the purpose of material outgassing analysis submission?

What information must be reported on material outgassing analysis submission?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.