Get the free Material Safety Data Sheet

Get, Create, Make and Sign material safety data sheet

Editing material safety data sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material safety data sheet

How to fill out material safety data sheet

Who needs material safety data sheet?

Comprehensive Guide to the Material Safety Data Sheet Form

Understanding the Material Safety Data Sheet (MSDS)

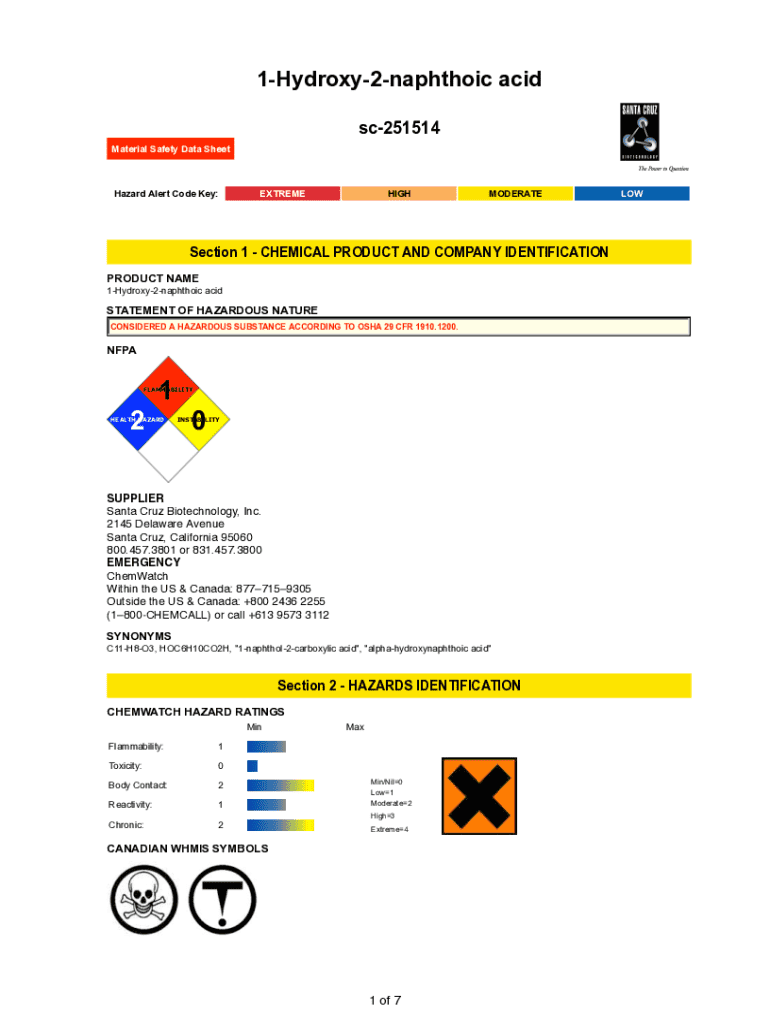

A Material Safety Data Sheet (MSDS) serves as a vital resource for workplace safety and risk management, detailing essential information about hazardous substances. It fulfills the fundamental role of communicating hazards associated with chemicals and ensuring that employees are equipped to handle them safely. The MSDS provides data on the properties, hazards, and safe handling practices for various materials, making it an indispensable element in promoting a safe working environment.

With stringent regulations governing workplace safety, organizations are required to provide workers with relevant MSDS documents. These sheets not only help protect employees but also align organizations with legal compliance requirements, thus mitigating potential workplace accidents and health risks.

Difference between MSDS and Safety Data Sheets (SDS)

The transition from MSDS to Safety Data Sheets (SDS) stems from the Global Harmonization System (GHS) initiative, which aims to standardize hazard communication globally. Unlike traditional MSDS, which could vary in format and content, SDS must adhere to a consistent 16-section format. Therefore, while both documents serve the purpose of hazard communication, the SDS offers improved clarity and uniformity, making it easier for users across different regions and industries to understand and utilize the information.

Understanding this distinction is crucial for compliance and safety protocol adherence. Employers must ensure that their employees are informed about the types of documents available and the importance of referencing the correct one.

Key Components of the Material Safety Data Sheet

An effective Material Safety Data Sheet is structured in a manner that allows for easy navigation and comprehension. The key sections of an MSDS or SDS encompass critical information necessary for safely handling hazardous materials.

Users engaging with MSDS/SDS should also be familiar with hazard pictograms as part of their hazard identification responsibilities. The GHS has defined specific pictograms that convey important visual cues about the hazards associated with chemicals. Understanding these symbols aids in recognizing risks and implementing the necessary safety measures.

How to obtain a Material Safety Data Sheet

Obtaining a Material Safety Data Sheet is a fundamental step for organizations that handle hazardous substances. Manufacturers and suppliers are required by law to provide these documents to customers, ensuring that everyone has access to vital safety information. To request an MSDS, simply contact the supplier directly and inquire whether they can provide a copy for the product in question.

In many cases, companies also maintain a database of MSDS for their products, often accessible on their websites. Stakeholders can easily search for specific chemicals or products through company catalogs and reporting tools.

Online resources for accessing MSDS

Several online platforms, including specialty databases and industry-related websites, offer an extensive collection of Safety Data Sheets. Users can utilize search functionalities to locate specific documents quickly, increasing efficiency in their operations. Some prominent resources for accessing SDS include:

Filling out the Material Safety Data Sheet form

Completing a Material Safety Data Sheet form necessitates precision and thoroughness, as accuracy is paramount for ensuring safety and compliance. The process begins with gathering all necessary data related to the product, including chemical properties, hazard information, and emergency response details.

Below are detailed steps to assist in filling out an MSDS:

Utilizing tools such as pdfFiller can also streamline this process, allowing users to fill, edit, and sign forms electronically, enhancing efficiency and ensuring better compliance. Features such as document storage and electronic signatures further simplify this task.

Editing and customizing your Material Safety Data Sheet

Utilizing platforms like pdfFiller for editing and customizing your Material Safety Data Sheet enhances the user experience and improves compliance. The seamless editing capabilities offered by pdfFiller enable users to modify content when necessary, ensuring the information remains current and accurate.

CustomiResponse in approach can greatly enhance your organization's safety documentation. Below are key tips for successful customization:

By leveraging collaborative features, teams can input relevant safety data collectively, enhancing the relevance and accuracy of each MSDS.

Managing and storing your Material Safety Data Sheets

Effective management and storage of Material Safety Data Sheets are essential components of maintaining workplace safety standards. Adopting digital management solutions can simplify this process and ensure easy access to these critical documents. Utilizing a cloud-based platform allows employees to access MSDS from anywhere, ensuring the latest information is always at hand.

Organizing MSDS within a central digital repository allows for quick retrieval and minimization of risk associated with outdated information. The following strategies can enhance your MSDS management:

Regulatory requirements and best practices

Understanding regulatory requirements surrounding Material Safety Data Sheets is crucial for ensuring compliance and promoting workplace safety. OSHA mandates that organizations disclose the hazards associated with chemicals and provide access to MSDS/SDS for employees. Compliance with these regulations not only safeguards employees but also protects organizations from potential legal liabilities.

Industries such as manufacturing, healthcare, and construction have specific guidelines that must be followed when managing hazardous materials. Regular audits and employee training are essential best practices for maintaining MSDS compliance, which can prevent mishaps stemming from misunderstanding or inadequate preparation.

Frequently asked questions (FAQs)

As material safety data sheets are integral to workplace safety, certain common questions often arise from users attempting to navigate compliance effectively.

Case studies and real-world applications

Numerous organizations have successfully leveraged Material Safety Data Sheets to proactively manage workplace safety and compliance. Industries like petrochemical, manufacturing, and food processing frequently use well-maintained MSDS to mitigate risks associated with hazardous materials.

For instance, a leading chemical manufacturer reduced accident rates significantly after implementing a robust MSDS management system that emphasized employee training and accessible documentation. Their case demonstrates how effective MSDS usage can lead to a safer work environment and promote an organizational culture centered on safety.

Key takeaways from such implementations can serve as valuable lessons, encouraging other organizations to adopt best practices in managing their MSDS, thereby enhancing safety and compliance across various settings.

Interactive tools and features

pdfFiller empowers users to streamline the MSDS management process through its innovative document creation toolbox. This cloud-based platform enhances user experience by allowing for seamless editing, signing, and collaboration while ensuring compliance.

Users have reported significant improvements in document management efficiency, reducing errors and simplifying the compliance process, thanks to pdfFiller's intuitive features.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my material safety data sheet in Gmail?

How do I make changes in material safety data sheet?

Can I sign the material safety data sheet electronically in Chrome?

What is material safety data sheet?

Who is required to file material safety data sheet?

How to fill out material safety data sheet?

What is the purpose of material safety data sheet?

What information must be reported on material safety data sheet?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.