Get the free Boiler, Pressure Vessels, Refrigeration Contractor Licence Application

Get, Create, Make and Sign boiler pressure vessels refrigeration

Editing boiler pressure vessels refrigeration online

Uncompromising security for your PDF editing and eSignature needs

How to fill out boiler pressure vessels refrigeration

How to fill out boiler pressure vessels refrigeration

Who needs boiler pressure vessels refrigeration?

Boiler Pressure Vessels Refrigeration Form - How-to Guide

Understanding boiler pressure vessels

Boiler pressure vessels play a critical role in industrial applications, particularly in maintaining efficient thermal energy storage and managing heat transfer. By containing fluids under pressure, these vessels allow for efficient heating processes essential in numerous manufacturing and production environments. Their structural integrity and performance directly influence system reliability, making them a vital component for engineers and operators alike.

Definition of boiler pressure vessels

A boiler pressure vessel is a sealed container designed to operate under high pressure and is primarily used for generating steam or heating water. They are constructed to withstand elevated temperatures and pressures, making them indispensable in industries requiring heat and power generation.

Key components

Essential components of boiler pressure vessels include valves, gauges, insulation, and piping systems. Valves control the flow and pressure within the vessel, while gauges provide vital information on temperature and pressure levels. Insulation prevents heat loss, supporting efficiency, and safety during operation.

Types of boiler pressure vessels

Boiler pressure vessels can be categorized into several types, including steam boilers that generate steam for power generation; hot water boilers designed for heating applications, and refrigeration units used in HVAC systems. Each type is designed based on specific operational needs and industry standards.

Regulations and standards for pressure vessels

Compliance with regulatory standards is crucial for maintaining safety and performance in boiler pressure vessel operations. These regulations ensure that all vessels are built to operate safely and effectively under pressure.

National and international codes

The ASME Boiler and Pressure Vessel Code is one widely respected regulatory framework in the United States that governs the design, manufacturing, and inspection of boiler pressure vessels. Internationally, similar guidelines exist, each contributing to improved safety standards across various countries.

Importance of compliance

Adhering to established compliance standards not only ensures the safety of operations but also enhances the reliability and longevity of the vessels. Non-compliance can lead to catastrophic failures, resulting in significant financial losses and operational downtime.

Overview of refrigeration processes in pressure vessels

Refrigeration processes within boiler pressure vessels are pivotal for various industrial applications, allowing for effective temperature management in critical operations such as food processing, chemical manufacturing, and HVAC design.

Basics of refrigeration

Refrigeration cycles involve the transfer of heat from a lower to a higher temperature area, effectively lowering the temperature in designated areas. This process typically includes phases such as compression, condensation, expansion, and evaporation, all essential to maintaining efficient cooling systems.

Applications of refrigeration in pressure vessels

In food processing and storage, refrigeration systems help maintain the freshness and safety of perishable products. In chemical manufacturing, cooling requirements are necessary for reactions and preserving product integrity. Each application showcases the versatility of boiler pressure vessels in supporting various industries.

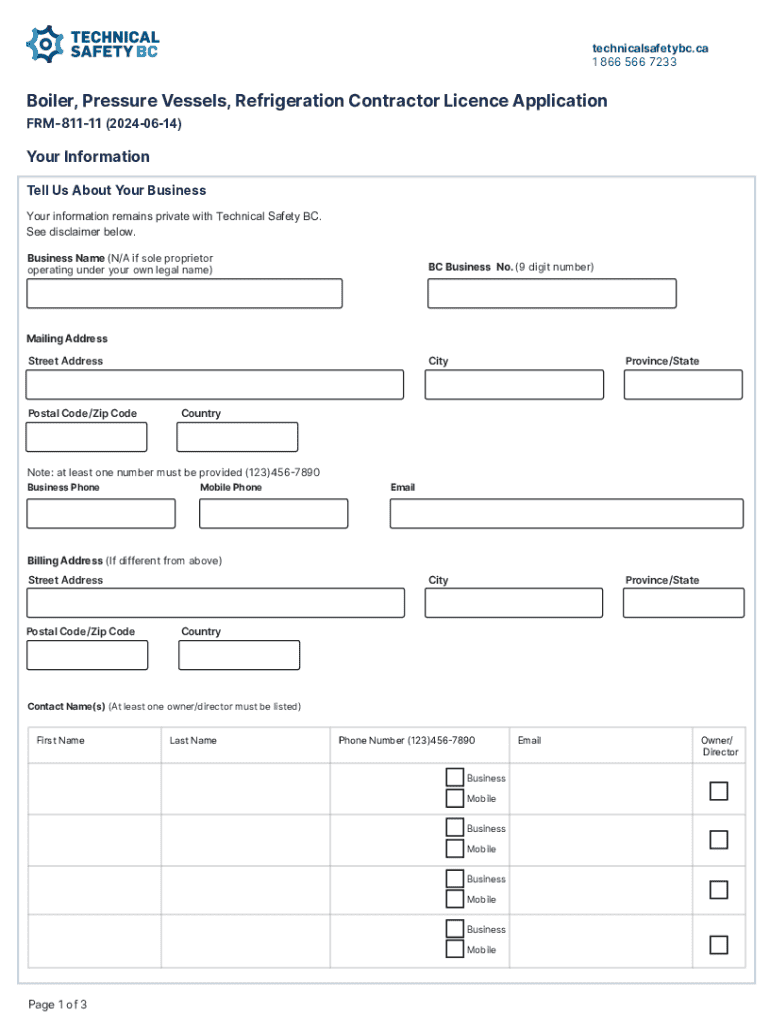

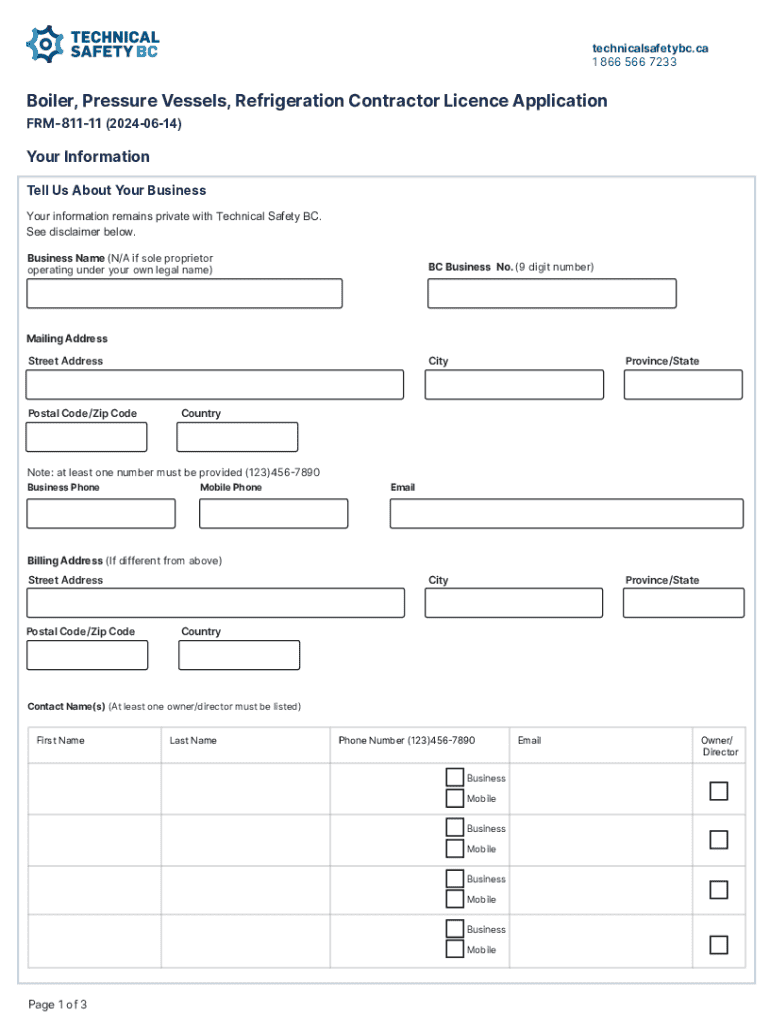

Filling out the boiler pressure vessels refrigeration form

Completing the boiler pressure vessels refrigeration form accurately is essential for ensuring compliance with industry standards and for effective maintenance tracking. This form serves as a documented assurance that all specifications and regulations have been met.

Purpose of the form

The primary purpose of this form is to gather vital information regarding the pressure vessel’s specifications, operational parameters, and compliance status to maintain safety and performance.

Step-by-step guide to completing the form

Editing and managing your form

Utilizing tools effectively allows for seamless management of your boiler pressure vessels refrigeration form. This capability ensures that documents remain up to date, compliant, and accessible.

How to edit PDF forms with pdfFiller

pdfFiller offers an intuitive platform for editing PDF forms. Users can easily add or modify text, checkboxes, and signatures, ensuring that the form reflects the most recent operational or compliance information.

Collaboration features

Collaboration tools available on pdfFiller allow multiple team members to work on the form simultaneously. This includes features for commenting, sharing, and version tracking, which streamlines team efforts and enhances efficiency.

Document management solutions

Effectively managing completed forms requires strategic organization. Proper storage solutions enable easy retrieval and ensure all documentation complies with regulatory requirements.

Common mistakes to avoid

Numerous mistakes can hinder the effectiveness of your boiler pressure vessels refrigeration form. Awareness of common pitfalls empowers users to submit accurate and professional documentation.

Frequently missed sections

Sections often overlooked include technical specifications and compliance checks. Missing details in these areas can lead to delays or rejections that ultimately impact overall project timelines.

Tips for avoiding errors

To ensure accuracy, double-check every entered detail before submission. Utilize the collaborative features of pdfFiller to seek input from colleagues, enhancing documentation quality.

Frequently asked questions (FAQs)

Understanding typical inquiries related to the boiler pressure vessels refrigeration form can ease the completion journey for many users.

Case studies in successful form completion

Examining real-world examples where companies utilized the boiler pressure vessels refrigeration form provides invaluable insights for those involved in similar tasks.

Real-world applications

One well-known case involved a chemical processing plant that efficiently integrated the form within their compliance workflow. The strategic documentation of specifications allowed them to seamlessly meet regulatory standards, resulting in a successful audit.

Lessons learned

Key takeaways from these experiences reveal the importance of proactive documentation practices and the inherent value of a centralized management platform like pdfFiller in keeping teams aligned.

Tools and resources for boiler pressure vessels

Leveraging the right tools can significantly enhance the process of managing boiler pressure vessels refrigeration forms and streamline document handling.

Interactive tools available on pdfFiller

pdfFiller provides interactive features that allow users to navigate through forms effectively, improve collaboration, and ensure that all documents are compliant with industry standards.

Additional documentation support

Access to further resources such as templates, guidelines, and industry standards documentation offer practical assistance for completing your forms accurately and efficiently.

Expert insights

Gaining insights from professionals in the field enhances understanding and application of best practices in managing boiler pressure vessels.

Interviews with industry experts

Engaging discussions with industry leaders reveal valuable perspectives on emerging trends and innovations within pressure vessel management and refrigeration technologies, allowing teams to stay ahead of the curve.

Innovations in pressure vessel design and maintenance

Continuous advancements in technology are enhancing the design and maintenance of pressure vessels. Innovations such as improved material compositions and automated monitoring systems are leading the industry toward safer and more efficient operations.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send boiler pressure vessels refrigeration for eSignature?

How do I make edits in boiler pressure vessels refrigeration without leaving Chrome?

How do I edit boiler pressure vessels refrigeration on an Android device?

What is boiler pressure vessels refrigeration?

Who is required to file boiler pressure vessels refrigeration?

How to fill out boiler pressure vessels refrigeration?

What is the purpose of boiler pressure vessels refrigeration?

What information must be reported on boiler pressure vessels refrigeration?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.