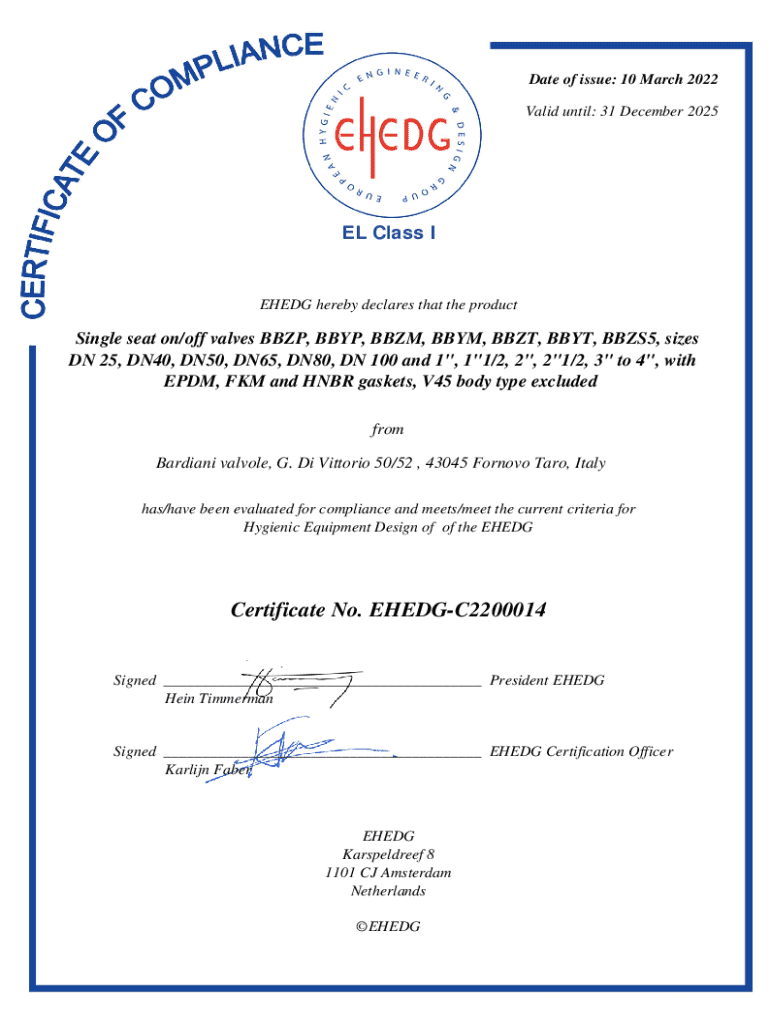

Get the free Requirements for valves in hygienic and aseptic processes

Get, Create, Make and Sign requirements for valves in

Editing requirements for valves in online

Uncompromising security for your PDF editing and eSignature needs

How to fill out requirements for valves in

How to fill out requirements for valves in

Who needs requirements for valves in?

Requirements for Valves in Form

Understanding the basics of valves

Valves are mechanical devices designed to control the flow of liquids, gases, and slurries within piping systems. Their primary function is to regulate stream flow, pressure, and direction, serving as crucial components in various industrial applications.

In a broad spectrum of industries, including oil and gas, manufacturing, and HVAC, valves ensure operational efficiency and safety. They are used to start, stop, or throttle flow, significantly impacting the performance of the systems they're incorporated into.

Key components of valves include the body, actuator, stem, and seat, all of which play critical roles in valve functionality. Understanding these basics is essential for identifying specific requirements for valves in form.

Requirements for selecting valves

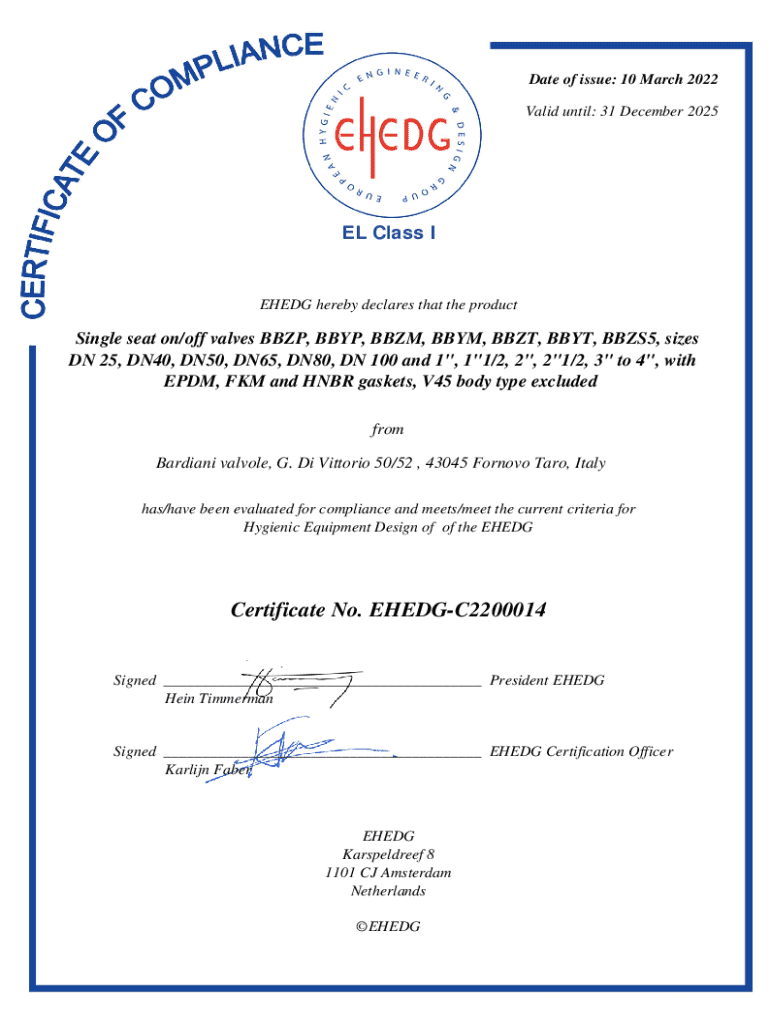

Selecting the right valve begins with an understanding of industry standards and regulations. Compliance with guidelines such as the American National Standards Institute (ANSI) and American Society of Mechanical Engineers (ASME) ensures that valves meet safety and performance criteria.

In addition to compliance, identifying application-specific considerations is vital. For instance, the requirements differ significantly when selecting valves for HVAC systems, plumbing, or chemical processing. Evaluating factors such as fluid characteristics, operating conditions, and flow requirements is paramount for effective valve selection.

Valve sizing and selection criteria

Proper valve sizing is critical for ensuring efficient operation. Incorrectly sized valves can lead to inadequate flow control, increased pressure drop across the system, and even potential system failure. The right size not only enhances efficiency but also improves the longevity of the valve.

Several factors influence valve size, notably flow rate specifications, which are determined based on the maximum expected flow. Furthermore, pressure drop considerations play a role; ensuring the valve can accommodate variations in pressure is crucial.

To calculate the proper valve size, one must follow a systematic approach. The formula involves variables such as flow rate, pressure differential, and fluid properties. Mistakes can arise from neglecting these factors, underscoring the importance of thorough analysis during a selection process.

Valve type exploration

Different valves serve distinct functions. Ball valves are best for quick on/off control due to their simple design and reliable sealing. In contrast, gate valves provide an ideal solution for on/off service but are less effective for throttling flow.

Butterfly valves are suitable for regulating flow, while check valves are vital for preventing backflow, a crucial function in various applications to protect equipment.

Understanding the advantages and disadvantages of each valve type helps ensure the selection of the right valve for specific operational needs. For example, ball valves offer durability and ease of use, while butterfly valves are compact and efficient for large flows.

Material selection for valves

Material selection plays a pivotal role in valve performance and longevity, with commonly used materials including metals and plastics. Metals, such as stainless steel, excel in high-pressure applications, while plastics may be suitable for corrosive environments.

Corrosion resistance is another critical consideration when selecting a valve. The right material must be compatible with the fluids being handled to prevent degradation and ensure seamless operation.

Compliance with material standards is vital to enhance performance and longevity. Understanding certifications is key to ensuring that the selected valve materials meet both operational needs and industry regulations.

End connections and valve fit

End connections are crucial to valve installation and operation. The choice lies primarily among threaded, flanged, and welded connections, each with specific installation requirements and applications.

Selecting the correct end connection is essential for ensuring leak-free operation and maintaining the integrity of the piping system. Improper fits or connections can lead to significant operational challenges, including leaks and pressure drops.

To guarantee proper fit and sealing effectiveness, consider factors such as alignment, tolerances, and assembly techniques. This meticulous attention to detail will enhance valve performance and reduce maintenance needs.

Operational parameters and test requirements

Operational parameters significantly affect valve selection, with temperature and pressure ratings being among the most crucial. Valves must be rated appropriately to handle expected conditions without failure.

Testing protocols ensure that valves meet operational expectations. Hydrostatic and performance testing serve as benchmarks for confirming that valves perform as intended under various conditions.

Additionally, establishing a maintenance and inspection schedule is critical for extending the life of valves and ensuring operational integrity. Regular assessments can identify wear and tear, enabling proactive interventions.

Leveraging document creation for valve requirements

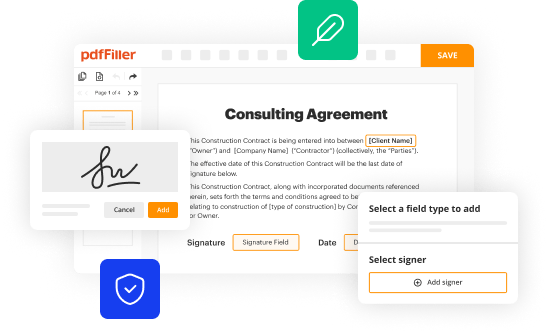

Utilizing a platform like pdfFiller streamlines the documentation process related to valve requirements. It allows users to create tailored forms that accurately capture data needed for valve selection, compliance, and operational tracking.

Moreover, pdfFiller's real-time collaboration features enhance team efficiency, allowing team members to work on documentation simultaneously from different locations, thus expediting decision-making processes.

Additionally, eSigning capabilities simplify the management of essential documents, ensuring secure storage and easy access to valve-related documentation from any device, promoting a flexible work environment.

Interactive tools for valve sizing and selection

Interactive tools provide invaluable resources to ensure accurate valve sizing and selection. Using online calculators, users can input specific parameters such as flow rate and medium properties to derive suitable valve options.

Leveraging tools available on platforms like pdfFiller not only aids in creating documents but also enhances the valve selection process, providing users with instant feedback based on input metrics.

When utilizing tools for valve documentation, a step-by-step approach ensures that users do not overlook critical requirements. This structured methodology provides confidence in the decision-making process and facilitates compliance.

Frequently asked questions

Throughout the valve selection process, users often have specific inquiries about the detailed requirements for valves. Common questions can include: what specifications are necessary when choosing a valve, how to ensure compliance with standards, and tips for selecting the correct material.

Addressing these questions not only enhances understanding but fosters confidence in selecting and managing valves effectively. By clarifying misconceptions regarding valve requirements, users can make informed decisions that align with their operational goals.

Ultimately, seeking expert opinions and utilizing available resources can significantly support individuals and teams in navigating the complexities surrounding valve requirements.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my requirements for valves in in Gmail?

How do I edit requirements for valves in in Chrome?

Can I create an electronic signature for signing my requirements for valves in in Gmail?

What is requirements for valves in?

Who is required to file requirements for valves in?

How to fill out requirements for valves in?

What is the purpose of requirements for valves in?

What information must be reported on requirements for valves in?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.