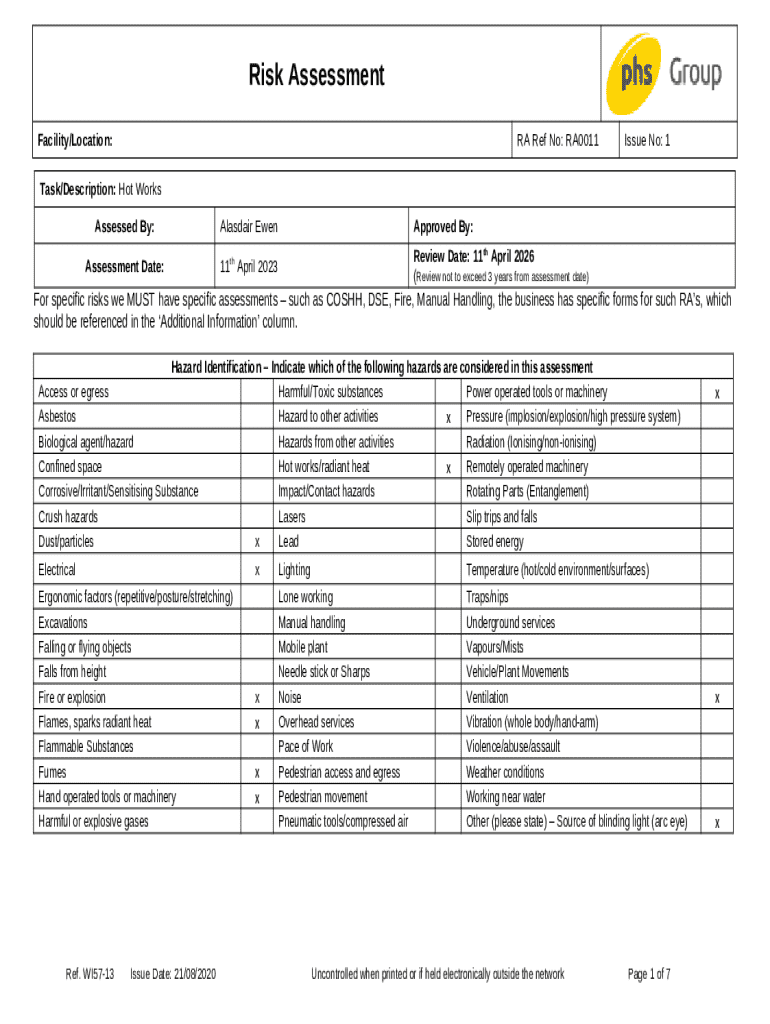

Understanding Hot Works Risk Assessment Form

Understanding hot works

Hot works refer to any activity that generates flames, sparks, or heat, which can serve as an ignition source for potential fire hazards. Common processes such as welding, cutting, soldering, and grinding fall within this category. Industries that frequently engage in hot works include construction, manufacturing, and shipbuilding, where materials are often subjected to high temperatures.

In the realm of occupational safety, assessing the risks associated with hot works is paramount. This ensures that all necessary precautions are put in place to prevent incidents that could lead to fires or explosions. A thorough risk assessment is crucial, not only for compliance with regulatory requirements but also for promoting a culture of safety and responsibility in the workplace.

Purpose of the hot works risk assessment form

The primary objective of the hot works risk assessment form is to systematically identify potential hazards associated with hot work activities. This document guides teams in documenting risks and establishing control measures to mitigate those dangers. A comprehensive risk assessment form ensures that all potential risks are considered and managed effectively.

Identify and document hazards associated with hot works.

Evaluate the level of risk linked to identified hazards.

Determine and outline necessary control measures.

Assign responsibilities for implementing safety precautions.

Document findings and maintain records for compliance and review.

Using an official hot works risk assessment form not only enhances safety protocols but serves as a documented assurance for adherence to regulatory standards, potentially mitigating liability in case of incidents.

When to use the hot works risk assessment form

Regulatory guidelines typically mandate the use of a hot works risk assessment form in various scenarios, particularly when conducting activities involving welding, cutting, or grinding. It is essential to evaluate the risks before any hot work begins, ensuring suitable precautions are taken to prevent accidents.

Before initiating any hot work tasks, such as welding or cutting.

In environments where flammable materials are present.

During periodic assessments or when changes to work areas occur.

When modifying procedures or introducing new hot work processes.

Regular assessments are crucial, especially in dynamic environments where conditions can change. Scheduled reviews not only help keep safety measures relevant but also ensure that all personnel remain aware of potential hazards and mitigation strategies.

Who should use the hot works risk assessment form

The hot works risk assessment form is ideally suited for safety officers, project managers, and contractors who oversee hot work activities. Each member of the team has a role to play in ensuring safety, which begins with understanding the contents and nuances of the risk assessment.

Safety Officers: Ensure compliance and provide guidance on safety measures.

Project Managers: Oversee project execution while emphasizing safe work practices.

Contractors: Follow directive measures and uphold safety standards on-site.

Workers: Participate in assessments and adhere to prescribed safety protocols.

Training on how to complete and use the hot works risk assessment form effectively is essential. Understanding the roles and responsibilities fosters collaboration and strengthens the overall commitment to workplace safety.

How to fill out the hot works risk assessment form

Completing a hot works risk assessment form involves a structured approach that facilitates thorough analysis and documentation. Here’s a step-by-step guide.

Identifying the site and context: Clearly specify the location and type of hot work operations.

Evaluating potential hazards: Identify specific risks associated with the tasks being performed.

Determining control measures: Specify the safety measures, protective equipment, and fire watches required.

Assigning responsibility: Designate who is responsible for implementing each control measure.

Documenting findings and signatures: Ensure that all documentation is complete, signed, and dated.

Accurate documentation is vital not only for compliance but also for future reference. Ensuring that each section is completed thoughtfully enhances the reliability of the risk assessment and its outcomes.

Key components of the hot works risk assessment form

Each hot works risk assessment form must include critical sections that provide a detailed breakdown of hazards and control measures to ensure comprehensive safety evaluations.

Hazard Identification: Listing all potential fire hazards and ignition sources.

Risk Evaluation: Assessing the likelihood and severity of identified risks.

Control Measures: Outlining required safety procedures, including personal protective equipment (PPE) like gloves and helmets.

Emergency Procedures: Specifying the actions to take in the event of an incident.

Understanding and thoroughly addressing each component is vital for maintaining a safe working environment. This not only protects workers but also minimizes operational disruptions.

Common pitfalls to avoid in hot works risk assessments

Not all risk assessments yield effective results, and common pitfalls can lead to inadequate safety measures. Recognizing these can enhance effectiveness.

Misunderstanding Hazard Scenarios: Failing to identify all potential hazards that may arise.

Inadequate Risk Control Measures: Relying on incomplete or outdated procedures to mitigate risks.

Failure to Update Assessments Regularly: Neglecting to reassess in changing environments can lead to serious oversights.

Awareness of these pitfalls can lead to more diligent preparation, stronger protocols, and a robust safety culture within the organization.

Legal considerations

Understanding the legal framework surrounding hot works is vital for compliance and risk mitigation. Regulatory bodies impose standards for hot work operations, with significant repercussions for non-compliance.

Regulatory Compliance: Ensuring adherence to federal, state, and local regulations.

Liability Issues: Being aware that lack of a proper assessment may expose organizations to legal repercussions.

Necessary Certifications: Confirming that all hot work personnel are adequately certified.

Documentation of the assessment process is crucial, as it provides necessary evidence of due diligence and compliance in the event of an inquiry or legal action.

FAQs about hot works risk assessment forms

Several common questions arise regarding hot works risk assessment forms, revolving around responsibilities and legal requirements.

How often should the hot works risk assessment be conducted? Typically, assessments should be revisited frequently, especially when conditions change.

Who is responsible for completing the form? It’s a collaborative effort, often involving safety officers, supervisors, and workers.

What are the legal implications of not conducting a risk assessment? Non-compliance could result in sanctions and liability in case of incidents.

Interactive tools for enhanced risk assessment

The advent of digital solutions has revolutionized the way risk assessments can be documented and managed. Tools that allow for real-time collaboration and edits can significantly enhance the efficiency of the hot works risk assessment process.

Digital platforms like pdfFiller provide easy access to and modification of assessment forms.

PDF editing tools enable users to customize forms quickly while maintaining professional standards.

Mobile access allows teams to manage assessments anywhere, enhancing flexibility.

E-signature integration streamlines approval processes, fostering faster workflows.

Utilizing these interactive tools not only improves the assessment process but also ensures that teams remain agile and responsive to evolving safety needs.

Related risk assessments for comprehensive safety management

A comprehensive safety management system incorporates various risk assessment forms to cover different work scenarios. Beyond hot works, several other assessments are equally critical.

Electrical Work Risk Assessment: Vital for managing risks associated with electrical installations.

Excavation Risk Assessment: Necessary for identifying hazards during underground operations.

Working on Ladder Risk Assessment: Important for ensuring safety during height-related tasks.

Tower Crane Risk Assessment: Addressing specific hazards related to crane operations.

Comparing the hot works risk assessment with others highlights Synergies in safety management approaches and the benefits of a holistic risk management framework.

Real-life case studies and examples

Examining various case studies related to hot works risk assessments sheds light on their importance and effectiveness. Successful implementations demonstrate the efficacy of risk assessments in preventing incidents.

A well-planned hot works assessment led to a significant reduction in fire incidents in a manufacturing plant.

Lessons learned from an incident involving inadequate risk assessment highlighted the need for thorough documentation.

Testimonials from workers and managers outline the positive impacts of utilizing structured risk assessments on overall safety culture.

These examples reinforce the importance of a detailed hot works risk assessment form that includes all necessary components for effective hazard management.

Business information and contact

pdfFiller offers a powerful platform designed to empower users in the creation, editing, and management of documents, including essential risk assessment forms. It provides users with unparalleled access to interactive tools that enhance document collaboration.

Explore pdfFiller’s features to effortlessly manage your hot works risk assessment form.

Contact us for personalized assistance or insights into making the most of the platform.

Handy links to related resources

For further information on hot work risk assessments and safety measures, utilizing external resources is beneficial. Regulatory bodies often provide guidelines to help organizations comply with safety standards.

Links to safety standards set by agencies like OSHA.

Access to articles that delve into safety protocols in hot works.

Networks and organizations focused on occupational safety may offer additional resources.

Recent posts on safety and risk assessment

Staying updated on best practices in risk management is crucial for safety professionals. Recent advancements in safety equipment and training methodologies also warrant attention.

Industry best practices are continually evolving—documentation and adherence ensure safety.

Innovations in safety gear improve worker protection and reduce hazard exposure.

Ongoing training and upskilling for workers ensure competency in safety protocols.