Material Safety Data Sheet Form - How-to Guide Long-read

Overview of material safety data sheets (MSDS)

A Material Safety Data Sheet (MSDS) is a document that provides essential information about the properties, handling, and hazards of chemicals. MSDSs are crucial in any environment where hazardous materials are used or stored, ensuring that employees are informed about the risks and necessary precautions. The significance of having an MSDS goes beyond compliance; it forms the backbone of workplace safety by providing clear guidance on how to safely handle, store, and dispose of hazardous substances.

MSDS and Safety Data Sheets (SDS) are terms often used interchangeably, yet they have subtle differences. While MSDS was the standard terminology used previously, the transition to SDS is now a global norm due to the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals. Consequently, SDS documents provide a more standardized format that enhances clarity and effectiveness in communication about chemical hazards.

Structure and elements of a material safety data sheet

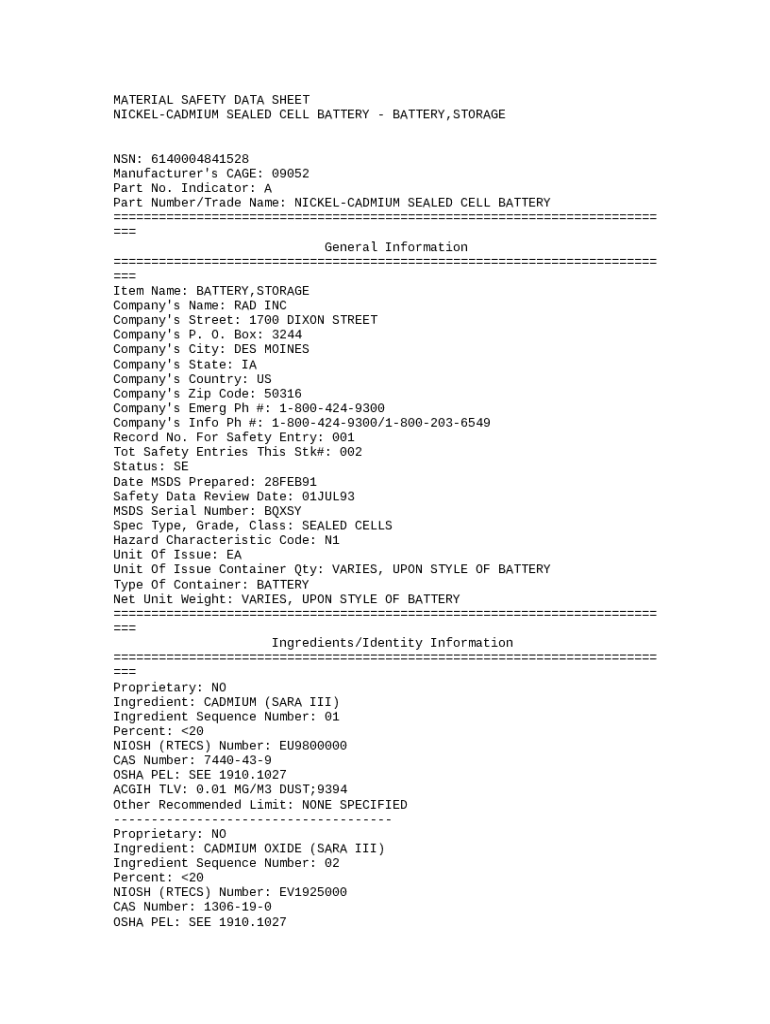

Understanding the layout of an MSDS is vital for its effective use. A fully equipped MSDS typically consists of 16 specific sections, each designed to convey critical safety and handling information.

Identification of the substance/mixture and supplier: Includes names, contact details, and emergency numbers.

Hazard identification: Outlines potential hazards with GHS pictograms to visually represent risks.

Composition/information on ingredients: Lists chemical components and their concentrations.

First-aid measures: Provides information on necessary first-aid procedures.

Firefighting measures: Details suitable extinguishing techniques and procedures.

Accidental release measures: Advises on how to respond to spills or leaks.

Handling and storage: Safe practices for storing and utilizing the chemical.

Exposure controls/personal protection: Recommendations for minimizing exposure and necessary protective equipment.

Physical and chemical properties: Information on the chemical's characteristics.

Stability and reactivity: Stability of the substance under various conditions.

Toxicological information: Health risks associated with exposure to the chemical.

Legal requirements and compliance

In the United States, the Occupational Safety and Health Administration (OSHA) mandates that companies maintain an up-to-date MSDS for every hazardous chemical they use. Compliance requires employers to ensure that employees have access to these sheets, as they are integral in facilitating safe practices within the workplace. The regulations are designed not only to protect workers but also to ensure that companies adhere to industry standards and avoid legal repercussions.

With the adoption of the Globally Harmonized System (GHS), MSDS documentation has transitioned to a standardized approach that enhances clarity and communication internationally. Companies must regularly review and update their MSDS to remain compliant, considering any new research on the chemicals they utilize.

How to fill out a material safety data sheet form

Filling out a Material Safety Data Sheet Form requires careful attention to detail. The following steps will guide you in creating an accurate and comprehensive MSDS:

Gather necessary information about the product: Collect all relevant data, including chemical properties and safety information.

Fill in each section using clear and concise language: Prioritize accuracy and ensure that every section is addressed.

Review for accuracy and completeness: Double-check all entries and confirm that nothing is omitted.

Common mistakes to avoid include skipping critical sections, using vague language, and failing to keep the MSDS updated with the latest information. Make sure that responsible personnel review the document periodically to maintain compliance.

Editing and customizing your MSDS with pdfFiller

pdfFiller provides a robust platform for editing and managing your Material Safety Data Sheets. Its user-friendly features enable effortless customization and collaboration.

Upload the MSDS template: Begin by importing your existing MSDS document.

Use editing tools to customize the form: Modify sections to tailor the document to your specific needs.

Apply electronic signatures: Utilize eSignature capabilities for efficient document validation.

Save and share your MSDS seamlessly: Ensure easy access across your organization.

Collaborating on MSDS with teams

Collaboration is essential in developing accurate and effective MSDS documents. pdfFiller allows multiple team members to work on the same MSDS, enabling real-time feedback and suggestions.

Best practices for sharing MSDS within your organization include establishing a clear communication protocol, designating responsible personnel for updates, and implementing regular review sessions. Managing feedback and revisions effectively via pdfFiller’s collaborative tools enhances the quality and compliance of your MSDS.

Finding and managing MSDS online

Accessing Material Safety Data Sheets online can be streamlined using pdfFiller’s interactive tools. Users can search for existing MSDS using key criteria, making it easy to find necessary documents on various substances.

The features of the safety data sheet search function enable quick retrieval of documents while ensuring that the most current versions are readily available for reference. Storing MSDS in an organized manner within the pdfFiller platform ensures that employees can find the information they need when they need it.

Safety and compliance best practices

Maintaining a culture of safety and compliance starts with regular reviews and updates of your MSDS. It’s crucial for organizations to integrate MSDS management into their safety programs, ensuring that all employees are trained on the potential risks associated with the substances they handle.

Effective training sessions can foster greater understanding of MSDS contents and enhance safety practices. Ongoing education and integration with compliance initiatives create a stronger safety culture within your workplace.

Additional considerations

For global companies, providing MSDS in multiple languages is essential to ensure that all personnel understand the hazards and precautions associated with chemicals they may encounter. As regulatory standards continue to evolve, the future of MSDS may see greater reliance on digital communication and real-time updates, making it easier for employees to access critical information.

Case studies demonstrate that organizations that implement solid MSDS processes reap benefits like reduced accidents and improved compliance with safety regulations. By prioritizing effective MSDS management, companies can significantly enhance their overall safety culture.

Resources and tools

To further enhance your understanding and management of MSDS, consider exploring a variety of external resources. pdfFiller offers interactive tools specifically designed to improve MSDS functions, ensuring that users can easily navigate, edit, complete, and share these important documents.

Additionally, users can benefit from FAQs that address common concerns about MSDS, their components, and managing these forms within the pdfFiller platform. Leveraging such resources can lead to more informed practices and effective compliance within your organization.