Get the free Ultra High Pressure Technology

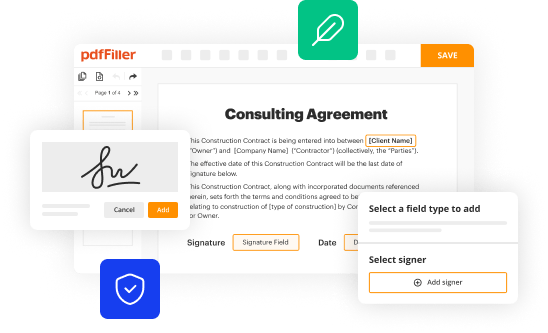

Get, Create, Make and Sign ultra high pressure technology

Editing ultra high pressure technology online

Uncompromising security for your PDF editing and eSignature needs

How to fill out ultra high pressure technology

How to fill out ultra high pressure technology

Who needs ultra high pressure technology?

Ultra High Pressure Technology Form: A Comprehensive Guide

Understanding ultra high pressure technology (UHPT)

Ultra High Pressure Technology (UHPT) refers to methods and processes that apply high pressure, often exceeding 1000 MPa (megapascals), to alter the physical and chemical properties of materials. This technology has evolved significantly since its inception in the mid-20th century, primarily driven by advancements in high-pressure equipment and the quest for innovative applications across various sectors.

The historical development of UHPT is rooted in the need for effective sterilization methods, particularly in the food industry. Pioneered in the 1990s, UHPT has gained recognition for its ability to enhance food preservation while maintaining nutritional quality. The importance of UHPT cannot be understated; it provides solutions that are not only efficient but also cater to growing demand for sustainability in manufacturing and food processing.

Core principles of UHPT

The fundamental mechanism behind UHPT operates on the principle of applying intense pressure to materials, which leads to significant changes in their physical attributes. Unlike traditional methods, which might rely on heat or chemical agents to alter material structure, UHPT uses pressure as the primary driver for reactions. This process can lead to enhanced product quality and preservation.

Key materials and equipment include specially designed pressure vessels and pumps capable of withstanding extreme conditions. Common materials used in UHPT include stainless steel and other alloys, which ensure safety and durability under high pressures. The choice of equipment is crucial, as failures during operations can be catastrophic, underscoring the need for quality machinery and routine maintenance.

Applications of ultra high pressure technology

Various industries leverage UHPT for its unique benefits. In the food and beverage sector, UHPT is used for processing techniques such as high-pressure processing (HPP) which helps in preserving food without degrading its natural taste and nutritional value. This method extends shelf life while keeping harmful microorganisms at bay.

In manufacturing, UHPT strengthens materials by tightly compressing them, which can lead to reduced waste and improved overall product lifespan. The medical and pharmaceutical sectors utilize UHPT for sterilization and the development of drugs, ensuring safety and efficacy in their products. Emerging fields, like environmental technologies, are also beginning to adopt UHPT for waste recycling and treatment processes.

Step-by-step guide to utilizing ultra high pressure technology

To effectively implement UHPT, first assess the need by identifying suitable products or processes. Evaluating cost-benefit scenarios ensures you are making an informed decision. Understanding the specific requirements of your product is essential to determine if UHPT can yield the desired outcomes.

Next, choose suitable high-pressure equipment. A variety of machines are available, and the selection should consider ease of use, capacity, and reliability. Be sure to conduct thorough research to select appropriate systems that align with your operational needs.

Preparing materials for UHPT involves pre-processing needs such as washing, cutting, or packaging. The packaging used must be able to withstand high pressure while ensuring product integrity. Once everything is set, implement the UHPT process by carefully setting up the equipment, conducting initial trials, and closely monitoring pressure and time parameters to ensure safety and effectiveness.

Benefits of ultra high pressure technology

The use of UHPT offers significant benefits. Enhanced product quality is evident as UHPT preserves flavors, colors, and nutritional value that heat-based methods might compromise. For example, fresh juices treated with UHPT retain their vibrant colors and flavors much better than those treated with heat.

Environmental benefits also accompany UHPT as it often reduces the need for chemical additives and lowers overall energy consumption compared to thermal treatments. This results in a more sustainable manufacturing approach, providing an environmentally friendly alternative that meets modern consumer expectations.

Potential challenges in implementing UHPT

While the benefits are substantial, challenges exist in the implementation of UHPT. Common technical difficulties may include equipment failures, which necessitate considerable investment in training for both maintenance and operational procedures. Pressure management issues can arise if the system is not maintained correctly, potentially leading to safety hazards.

Regulatory considerations are another hurdle, as adherence to safety standards is crucial. Organizations must ensure compliance with industry requirements, obtaining necessary certifications for their equipment and processes to avoid legal repercussions. Cost factors also play a critical role; transitioning to UHPT may demand significant upfront investment, which must be carefully evaluated against long-term gains.

Best practices for maintaining ultra high pressure systems

To maximize the efficacy and longevity of UHPT systems, regular maintenance protocols are vital. Scheduled inspections should occur to assess wear and tear, ensuring that any potential issues are identified early. A cleaning and calibration routine will help keep the equipment functioning at optimal levels.

Training staff on equipment use also plays an essential role in optimization. Implementing safety training programs will not only secure operations but can also improve efficiency. Encouraging continuous learning and adaptation in the workforce is key as technology continues to develop and improve.

Future trends and innovations in ultra high pressure technology

Looking ahead, emerging research initiatives are expected to expand the capabilities of UHPT. Innovations such as the integration of artificial intelligence and smart technology can enhance the monitoring and control of pressure systems, increasing safety and efficiency in operations. These technological advancements signal a promising future, broadening the application of UHPT across more industries.

Market forecasts indicate significant growth opportunities for UHPT. As industries increasingly prioritize sustainability and efficiency, those who invest in advanced UHPT methods will likely gain a competitive advantage. This reflects a broader market trend where ecological consciousness and technological progress continue to intersect.

User success stories with ultra high pressure technology

Several case studies illustrate the successful implementation of UHPT in the food processing industry. For instance, leading juice manufacturers have adopted HPP technology, achieving a significant reduction in spoilage rates while enhancing flavor profile and nutritional preservation. Testimonials from these innovators highlight the transformative impact that UHPT has had on their business operations, emphasizing the technology's role in improving product offerings.

In the medical sector, hospitals utilizing UHPT for sterilization report elevated levels of safety, making equipment preparation more reliable than traditional methods. Early adopters in these fields have documented their experiences, offering insights into the operational adjustments and benefits that UHPT brings to both product life cycles and market positioning.

Interactive tools and resources for users

To support users in their journey with UHPT, interactive tools can streamline the implementation process. A usage calculator can allow businesses to estimate the impacts of applying UHPT across different products effectively. Additionally, an interactive FAQ section can address common challenges, helping new adopters navigate the complexities of high-pressure technology.

For those seeking tailored advice, a submission form for personalized consultations on UHPT implementation can provide insights specific to their needs. These resources ensure that whether you are an established company or a newcomer to the field, support is readily available to optimize your utilization of Ultra High Pressure Technology.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find ultra high pressure technology?

How do I make edits in ultra high pressure technology without leaving Chrome?

Can I edit ultra high pressure technology on an iOS device?

What is ultra high pressure technology?

Who is required to file ultra high pressure technology?

How to fill out ultra high pressure technology?

What is the purpose of ultra high pressure technology?

What information must be reported on ultra high pressure technology?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.