Get the free Technical Information / Blower Sizing

Get, Create, Make and Sign technical information blower sizing

How to edit technical information blower sizing online

Uncompromising security for your PDF editing and eSignature needs

How to fill out technical information blower sizing

How to fill out technical information blower sizing

Who needs technical information blower sizing?

Technical Information Blower Sizing Form: A Comprehensive Guide

Understanding blower sizing

Blower sizing is a critical factor in ensuring optimal performance in various applications. When selecting a blower, proper sizing is essential to achieve the desired airflow and static pressure. Incorrect sizing can lead to inefficiencies and increased costs, making familiarity with the blower sizing form crucial.

Selecting the right blower affects not only performance but overall operational efficiency. An oversized blower can lead to considerable energy wastage, while an undersized blower may fail to meet the required airflow. This can lead to production downtimes, increased wear and tear on equipment, and higher maintenance costs. Thus, understanding blower sizing forms is vital.

Common applications for blowers

Blowers are utilized across various industries for multiple applications. Common uses include industrial processes, HVAC systems, and environmental control systems. Each application demands specific performance metrics from the blowers to function effectively.

In industrial settings, blowers are often used for drying materials or conveying bulk solids. In HVAC systems, they ensure the efficient circulation of air while maintaining desired indoor air quality. Additionally, environmental control systems leverage blowers to manage air pollution and improve air quality, underlining the need for precise blower sizing.

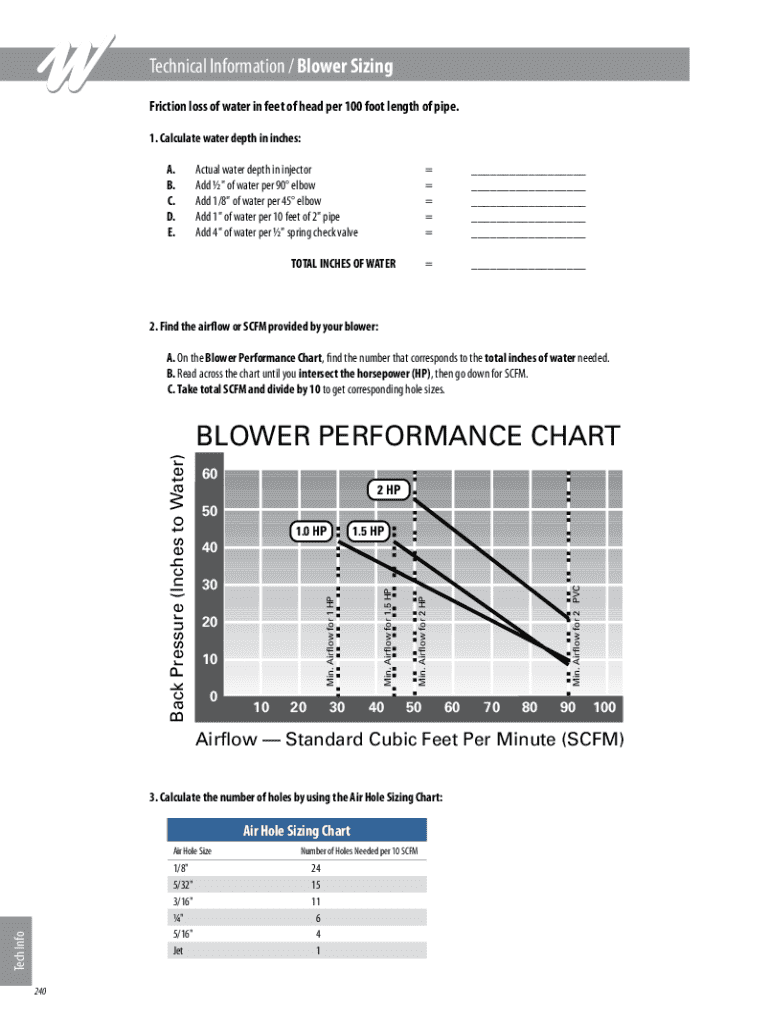

Key components of the blower sizing form

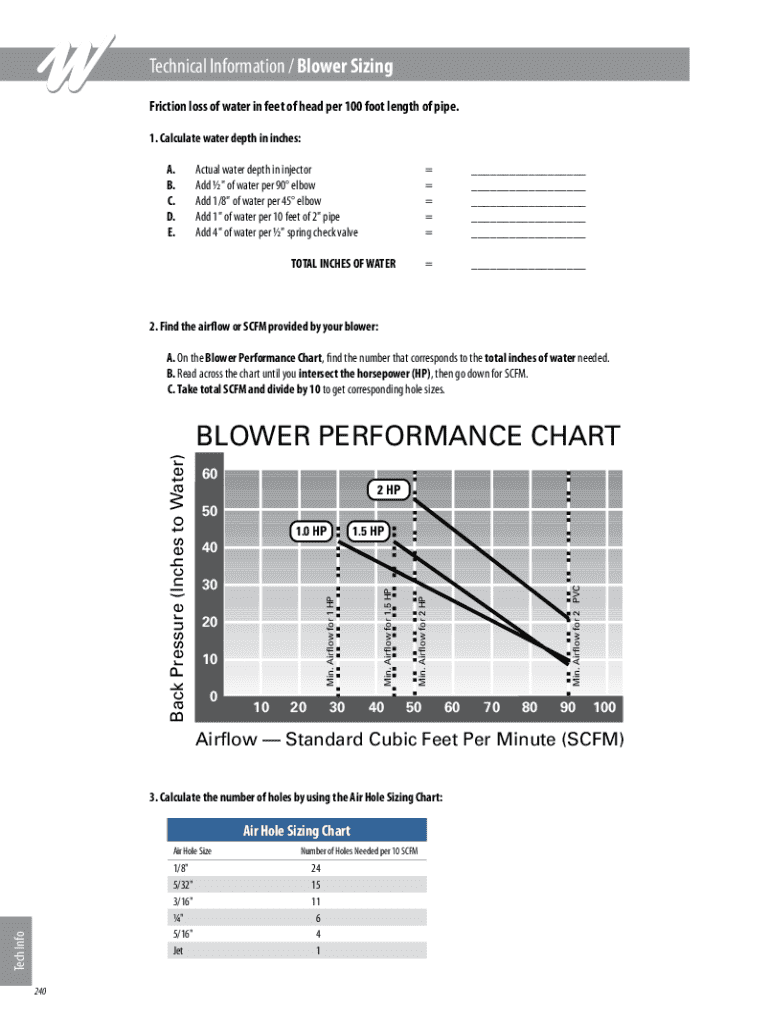

The blower sizing form consists of several critical input parameters necessary for selecting the appropriate blower. These include airflow requirements, static pressure specifications, and characteristics of the application environment. Gathering accurate data in these categories is pivotal for effective sizing.

Airflow requirements, denoted in cubic feet per minute (CFM), dictate the volume of air needed for successful operation. Static pressure, measured in inches of water gauge, indicates how much resistance the blower must overcome in the system. Understanding these elements is crucial for ensuring the selected blower can achieve targeted performance objectives.

Review of common terminology in blower sizing

Understanding the terminology surrounding blowers and their sizing is crucial for effectively filling out the form. CFM refers to the measurement of airflow generated by the blower, while static pressure is the pressure exerted by the air in a stationary system. Knowing the difference between total pressure and static pressure helps in evaluating blower performance effectively.

Velocity pressure, on the other hand, is related to the speed of the air moving through the system. Each of these terms contributes to a fuller understanding of how the blower's performance correlates to application needs, further underscoring the significance of accurate specifications.

Step-by-step guide to filling out the blower sizing form

Filling out a blower sizing form requires a systematic approach. Start by gathering basic information related to your specific application type. This will directly influence the necessary airflow rate and static pressure needed. Accurately identifying these elements is the first step toward effective sizing.

Once the application type is determined, input the static pressure values into the form. Be mindful of potential system losses due to fittings, ductwork, and other components that can hinder airflow. Measuring or estimating static pressure is critical for ensuring that the blower can perform efficiently within your system.

Considering environmental factors

Environmental factors can significantly affect the performance of blowers, making it essential to address them when sizing. Temperature and humidity levels should be factored in, as they can alter air density and influence blower efficiency. It’s important to consider how these elements fluctuate in your operational environment throughout the year.

Altitude is another critical factor impacting blower performance. At higher elevations, the reduced air density can affect how efficiently a blower operates. Adjustments may be necessary to ensure optimal performance, particularly in industries operating in varied geographical locations. Identifying the relevant environmental parameters before submitting your sizing form can enhance accuracy.

Reviewing special requirements

Special requirements can also influence the blower sizing process. Noise considerations may be crucial in specific applications, particularly in residential or public spaces where excessive noise can be detrimental. Selecting blowers designed for reduced operational noise levels can help avoid complaints and maintain project standards.

Additionally, understanding any regulatory or compliance standards related to your application is imperative. Industry-specific guidelines may dictate permissible noise levels or emissions, impacting the choice of blower technology. Regularly reviewing these requirements can ensure ongoing compliance and facilitate smoother operations.

Using interactive tools for blower sizing

Advancements in technology have made digital tools indispensable for blower sizing. Leveraging these interactive platforms allows users to perform instant calculations and receive quick results. Many digital tools are designed with user-friendly interfaces that simplify the process, reducing the burden of manual calculations.

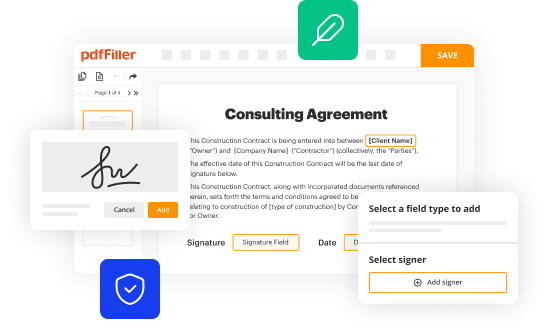

Integrating the blower sizing form into platforms like pdfFiller offers convenient access from any location. This ensures that the necessary forms are always available for completion and submission, enhancing productivity. Localizing the form for specific applications can further personalize the user experience, catering to unique industry needs.

Saving and sharing your sizing results

After filling out the blower sizing form, saving and sharing the results is seamless on platforms like pdfFiller. This allows users to edit completed forms as needed, ensuring that all changes can be tracked and updated efficiently. Collaborative features enable team members to access and input information, facilitating smoother project management.

Being able to share results quickly with stakeholders can assist in decision-making processes. This capability fosters effective communication and ensures that all parties involved remain informed, promoting better project outcomes.

Troubleshooting common blower sizing issues

Recognizing signs of incorrect blower sizing is vital for maintaining operational efficiency. Common indicators include insufficient airflow, which can lead to decreased productivity and potential project delays. Excessive noise or vibrations can indicate improper sizing, often leading to equipment failure or increased maintenance needs.

To address performance issues, a reevaluation of airflow needs may be necessary. This involves revisiting the application requirements and making adjustments to the blower system as needed. Employing the blower sizing form to reassess specifications regularly can prevent such issues from escalating and guarantee long-lasting efficiency.

Case studies: successful blower applications

In examining successful blower applications, specific industries have notably benefited from proper sizing. For example, chemical processing plants often require precise airflow to maintain reaction efficiencies, while the food and beverage industry relies on blowers for applications such as cooling and ingredient handling. Case studies within these fields demonstrate the importance of the blower sizing form in achieving optimal results.

Lessons learned from sizing mistakes in these industries reveal common pitfalls to avoid. For instance, neglecting to account for system losses can lead to significant performance issues. Adopting best practices for future projects, such as detailed calculations and collaborative sizing efforts, can enhance operational success.

Advanced topics in blower sizing

Emerging technologies are continually reshaping the landscape of blower efficiency. Variable speed drive technology allows blowers to adjust their operational speed, enhancing energy efficiency while meeting variable demand loads. Moreover, the integration of smart blower systems and IoT capabilities offers new monitoring solutions, enabling predictive maintenance and real-time performance analytics.

The environmental benefits of proper blower sizing also warrant attention. Adopting energy-efficient blowers contributes to reduced emissions and energy savings, reflecting a commitment to long-term sustainability in industrial operations. Companies can bolster their environmental stewardship while also enhancing operational efficiency by utilizing advanced blower technologies.

Explore additional services from pdfFiller

pdfFiller provides enhanced document management solutions that extend beyond basic form filling. Users benefit from eSignature capabilities that streamline approval processes while ensuring compliance and security. Collaboration tools make it easy for teams to work together on documents, enhancing productivity across projects.

Additionally, comprehensive support resources are available for users, including customer service options and an extensive FAQ section that addresses common blower sizing queries. Engaging with these resources ensures that you can maximize your use of the platform, maintaining efficiency and effectiveness across all documentation efforts.

Keeping up-to-date with industry trends

Staying informed about advancements in blower technologies is essential for professionals in the field. Following industry publications and webinars can provide insights into new best practices and innovative technologies that enhance blower efficiency. Joining professional organizations can also facilitate networking opportunities and access to valuable resources.

Anticipating upcoming innovations, such as predictive maintenance technologies, can significantly affect operational efficiency. Adapting quickly to changes in best practices helps organizations maintain a competitive edge while ensuring that their blower systems operate at peak performance.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find technical information blower sizing?

Can I create an electronic signature for signing my technical information blower sizing in Gmail?

How do I complete technical information blower sizing on an iOS device?

What is technical information blower sizing?

Who is required to file technical information blower sizing?

How to fill out technical information blower sizing?

What is the purpose of technical information blower sizing?

What information must be reported on technical information blower sizing?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.