Get the free Metallurgy Lab: Scratch Test

Get, Create, Make and Sign metallurgy lab scratch test

Editing metallurgy lab scratch test online

Uncompromising security for your PDF editing and eSignature needs

How to fill out metallurgy lab scratch test

How to fill out metallurgy lab scratch test

Who needs metallurgy lab scratch test?

Metallurgy lab scratch test form: A comprehensive guide

Overview of scratch testing in metallurgy

Scratch testing plays a pivotal role in evaluating the physical properties of materials, particularly metals. During this process, the degree of resistance a material demonstrates against grooves or scratches is assessed, which directly correlates to its durability and suitability for various applications.

Industries such as aerospace, automotive, and manufacturing rely heavily on precise and accurate scratch test results. For instance, aerospace components must withstand extreme conditions and mechanical wear, while automotive parts require durability against frequent use. In manufacturing, understanding the scratch resistance of materials can lead to improved quality and overall product longevity.

Understanding the scratch test

Scratch testing, by definition, involves applying a specific force on a material with a defined geometry to create a scratch. The primary goal is to evaluate the scratch resistance, which indicates how well a substrate can resist abrasive damage.

There are mainly two types of scratch tests conducted in laboratories: macro testing and micro hardness testing. Macro testing usually involves heavier loads and larger scratch geometries, whereas micro hardness testing focuses on smaller scales and is more sensitive to material properties. These tests are crucial for assessing not only the durability of materials but also for predicting their longevity under operational conditions.

Terminologies such as scratch resistance, abrasion, and wear are central to understanding scratch testing. Scratch resistance quantifies how well a material stands up to distortion, while abrasion measures the loss of material caused by friction. Wear refers to the gradual removal of material due to mechanical action, all of which are integral to evaluating overall material performance.

Preparing for the scratch test

Before conducting a scratch test, selecting the appropriate material is crucial. Each material has unique properties that can influence test results, thus careful consideration must be taken to align the test with the intended application.

Essential equipment includes a scratch testing machine and a variety of sample preparation tools. The machine applies force and measures results, while sample preparation tools ensure that the test samples are uniform. It is also critical to follow safety precautions, such as wearing personal protective equipment (PPE) and maintaining work area hygiene, to prevent any accidents or contamination during testing.

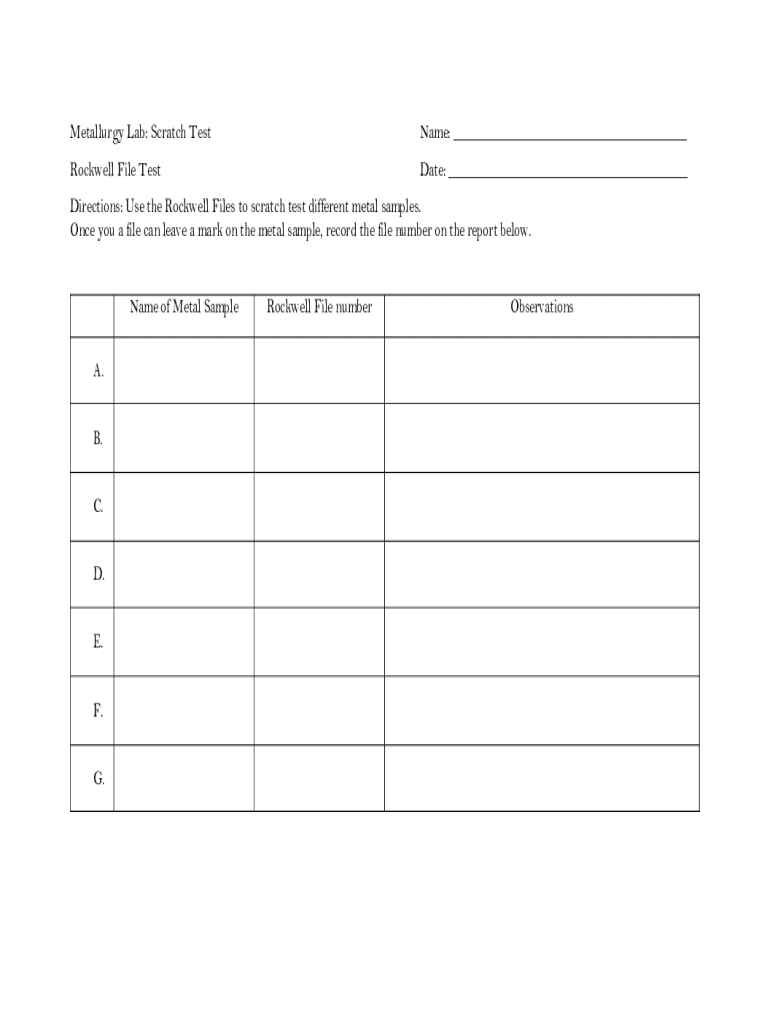

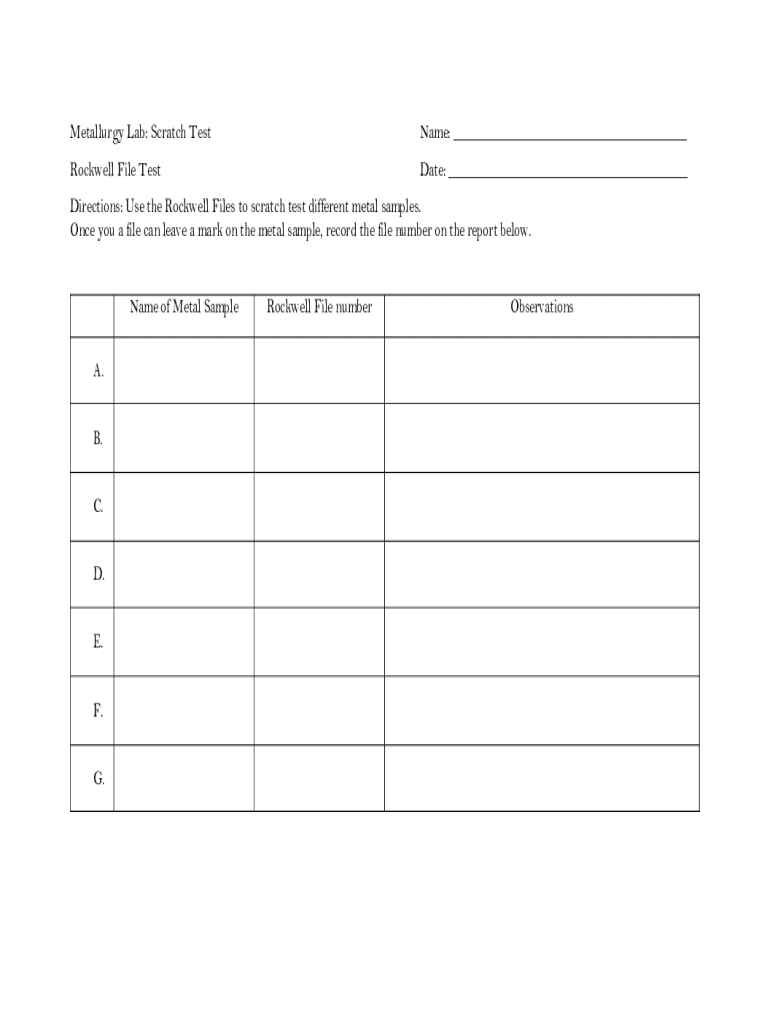

Step-by-step guide to filling the scratch test form

The scratch test form serves a vital purpose: it documents all relevant information regarding the scratch test, ensuring that results can be reproduced and assessed over time. Understanding the sections of the form is crucial for accurate documentation.

Each section typically contains specific information required to ensure clarity and utility.

Analyzing and interpreting scratch test results

After conducting the scratch test, analyzing the results is critical for informed decision-making in material selection. Precise measurement and reporting of scratch depth provide insight into material durability, while comparisons against industry standards can establish value.

The implications of these results extend beyond mere numbers. By understanding how a material performs under stress, buyers and engineers can make informed choices tailored to specific applications, thereby enhancing performance and longevity.

Using pdfFiller for scratch test form management

pdfFiller streamlines the management of your metallurgy lab scratch test form, offering several advantages such as cloud-based access and collaboration. Users can edit and eSign forms easily, enabling seamless document flow and efficiency.

Furthermore, pdfFiller provides interactive tools like customizable form templates and real-time collaboration features. These tools simplify the sharing and storing of completed forms, making them effortless to manage for teams who need to access the information remotely.

Common challenges and solutions in scratch testing

Scratch testing is not without its challenges. One common issue arises during sample preparation, where inconsistencies can lead to skewed results. Additionally, variations in test conditions can impact the accuracy of outcomes.

To overcome these complications, ensuring calibration of equipment and standardizing environmental conditions can significantly enhance reliability. Regular checks and maintenance will also mitigate errors, thus maintaining the integrity of your test results.

Case studies: Successful applications of scratch testing

Scratch testing has been successfully applied in various industries, yielding valuable insights. For example, in aerospace, specific components underwent rigorous testing to ensure reliability under extreme conditions. Similarly, automotive coatings were evaluated under scratch tests to assess wear resistance, leading to better products for consumers.

However, not all applications have resulted in success. Some failures stemmed from incorrect testing procedures or poor material selection. These lessons learned underline the importance of precise application of scratch testing techniques.

Future trends in scratch testing and materials evaluation

Emerging innovations in testing techniques promise to revolutionize the field of metallurgy. Advanced technologies such as digital imaging and automated testing platforms enhance the accuracy and efficiency of scratch tests.

Looking ahead, the integration of sustainable practices in scratch testing will also become more prevalent. As industries shift toward environmental consciousness, methods that reduce waste and improve the sustainability of materials will shape future practices in materials evaluation.

Frequently asked questions about scratch testing

Many questions arise concerning the scope and limitations of scratch testing. Key inquiries include the types of materials that can be tested, the frequency with which tests should occur, and the limitations inherent in the testing process.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find metallurgy lab scratch test?

How do I fill out the metallurgy lab scratch test form on my smartphone?

How do I edit metallurgy lab scratch test on an Android device?

What is metallurgy lab scratch test?

Who is required to file metallurgy lab scratch test?

How to fill out metallurgy lab scratch test?

What is the purpose of metallurgy lab scratch test?

What information must be reported on metallurgy lab scratch test?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.