Get the free Buffing / Polishing Basics

Get, Create, Make and Sign buffing polishing basics

Editing buffing polishing basics online

Uncompromising security for your PDF editing and eSignature needs

How to fill out buffing polishing basics

How to fill out buffing polishing basics

Who needs buffing polishing basics?

Buffing polishing basics form: A comprehensive guide

Understanding buffing and polishing

Buffing and polishing are two crucial processes involved in surface finishing, commonly employed to enhance the appearance and durability of various materials. Buffing primarily aims at smoothing surfaces while polishing enhances shine, often leaving a reflective finish. Both processes are indispensable in different industries, including automotive, woodworking, and metal fabrication. Their ability to remove scratches, blemishes, and oxidation makes them vital for restoring and maintaining the aesthetic and functional qualities of products.

In the automotive industry, buffing and polishing can breathe new life into dull or weathered surfaces, resulting in a gleaming finish that protects the paint. Similarly, in woodworking, these techniques are essential for achieving a smooth, polished look on furniture and cabinetry. Additionally, they are widely used in the manufacture of jewelry, electronics, and various consumer products, emphasizing their versatility across materials like metals, plastics, and wood.

Key concepts and terminology

To effectively understand buffing and polishing, it’s vital to grasp the distinctions between these two processes. Buffing generally uses a buffing wheel or cloth and is typically a coarser operation aimed at preparing a surface by eliminating imperfections. Polishing, conversely, often employs finer materials and techniques to create a high-gloss finish. This differentiation is crucial in selecting the appropriate method based on the desired outcome.

There are various methods for buffing and polishing, among which mechanical buffing and hand buffing are the most common. Mechanical buffing utilizes powered tools like rotary buffers designed for efficiency in larger tasks, while hand buffing provides a level of control ideal for detailed work or small surfaces. Chemical polishing employs specialized compounds that react with the material surface, often used in automotive applications to remove oxidation and produce a reflective finish. Familiarity with these methods ensures optimal results in your buffing and polishing endeavors.

Preparing for buffing and polishing

Before diving into buffing and polishing, it's essential to assess the surface you're working with thoroughly. This step includes inspecting for imperfections, such as scratches, dull areas, or oxidation, that might require different approaches. Once you've identified the surface condition, you must choose the appropriate methods and materials for buffing or polishing toward achieving your desired finish. This thoughtfulness often saves time and resources.

Safety is equally important in this preparation phase. Always wear protective gear, including safety goggles and gloves, to shield against debris and chemical exposure. Ensuring a safe working environment also involves maintaining good ventilation and keeping your workspace organized to prevent accidents. These precautions will not only safeguard you but also improve the overall efficiency of your project.

The buffing and polishing process

The buffing process consists of several critical steps. First, select the right pad for the material you're working with; this can vary from a soft foam pad for delicate surfaces to a more abrasive wool pad for tougher materials. Next, apply the chosen buffing compound to the pad, using a moderate amount to prevent spillage. As you buff, employ a slow, even technique, allowing the compound to work into the surface. Maintaining consistent pressure can enhance effectiveness while avoiding excessive heat buildup that may damage the workpiece.

Polishing follows a similar approach with a few adjustments. Start by preparing the surface, ensuring it’s clean and free from dust or residue. Apply a polishing compound to an appropriate pad, similar to buffing, but with lighter application for a finer finish. Use circular motions or straight lines to achieve a uniform shine while maintaining careful control over pressure. Overworking the surface can lead to uneven gloss, so a steady hand is crucial.

Troubleshooting common issues

While buffing and polishing can yield stunning results, various issues may arise during the processes. Streaks and swirls can occur due to dirt on the pad, inappropriate pressure, or using the wrong compound. To resolve this, ensure your pads are clean before application, and consider switching to a finer compound to finish the work. Additionally, adjusting your technique—slower and steadier may help alleviate these common issues.

Uneven shine is another frequent problem, often stemming from inconsistent application or technique. To fix this, reevaluate your method: ensure you’re applying even pressure and covering the surface uniformly. Material-specific issues can also become an obstacle, particularly with softer materials like acrylic that may become scratched more easily than harder metals. Researching the appropriate compounds and techniques for each material type can mitigate these hurdles effectively.

Advanced buffing and polishing techniques

For those looking to elevate their buffing and polishing game further, consider utilizing multiple stages for a superior finish. Starting with a coarser compound followed by progressively finer compounds can create an exceptionally smooth and glossy finish. This approach is commonly seen in high-end automotive detailing where professionals use various stages to achieve the best results.

Buffing out deep scratches requires a more attentive technique; beginning with a heavier cutting pad and gradually shifting to finer pads can help restore the material’s original appearance. While both professional and DIY approaches can yield results, understanding the specific nuances between them can help you leverage your skills effectively in various scenarios. Professional settings often employ sophisticated tools and products that may not be available to individual users, but with practice and the right materials, you can achieve professional-quality finishes in your own workspace.

Digital tools and solutions for buffing and polishing projects

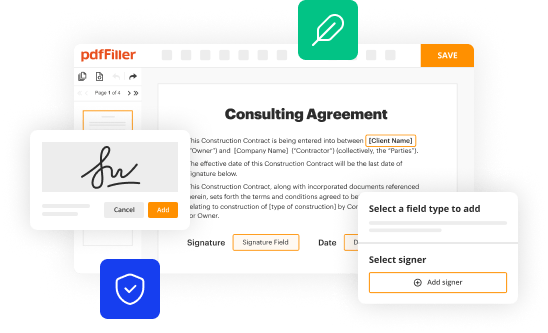

In today's digital age, utilizing tools like pdfFiller can significantly enhance your buffing and polishing projects by allowing you to document and manage your processes with ease. By creating forms such as project tracking documents, you can ensure every step of your project is recorded efficiently. This digital management approach enables you to plan better and keep track of all activities, which can ultimately improve workflow and outcome.

Collaboration becomes simplistic with tools like pdfFiller, which allows teams to share insights, techniques, and project updates in real time. The ability to edit documents collaboratively ensures every team member can contribute effectively, which is crucial when managing larger buffing and polishing projects where multiple inputs are essential.

Managing your buffing and polishing documentation

Maintaining comprehensive records of your buffing and polishing activities is crucial for both accountability and efficiency. Keeping detailed notes on the methods used, compounds applied, and results achieved enables you to standardize processes, learn from experiences, and replicate successful techniques in the future. This documentation can also serve as a valuable resource, especially when troubleshooting problems or training new team members.

Effective document management strategies include version control, allowing you to track changes in your documents and ensure that everyone is on the same page. Utilizing features available in pdfFiller, such as collaborative editing, can streamline your documentation process further. By enabling team members to review and provide feedback simultaneously, you create a robust system that enhances project outcomes.

Frequently asked questions about buffing and polishing

Many individuals have common queries regarding buffing and polishing. A frequent question is how often one should buff or polish surfaces — this generally depends on the usage and exposure of the item to environmental factors. Regularly used items may benefit from quarterly buffing, while occasional pieces may require less frequent attention.

Another common inquiry is regarding the use of household items for buffing and polishing; while some can be useful, ensuring they are suitable for the material is crucial to avoid damage. Lastly, individuals often wonder about the best compounds for different materials — selecting the correct compound tailored to the specific material can make a significant difference in the results achieved.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my buffing polishing basics in Gmail?

How do I complete buffing polishing basics online?

How do I edit buffing polishing basics in Chrome?

What is buffing polishing basics?

Who is required to file buffing polishing basics?

How to fill out buffing polishing basics?

What is the purpose of buffing polishing basics?

What information must be reported on buffing polishing basics?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.