Get the free Magnetic Particle Inspection Report - Welding

Get, Create, Make and Sign magnetic particle inspection report

Editing magnetic particle inspection report online

Uncompromising security for your PDF editing and eSignature needs

How to fill out magnetic particle inspection report

How to fill out magnetic particle inspection report

Who needs magnetic particle inspection report?

Magnetic Particle Inspection Report Form: A Comprehensive Guide

Understanding the magnetic particle inspection report

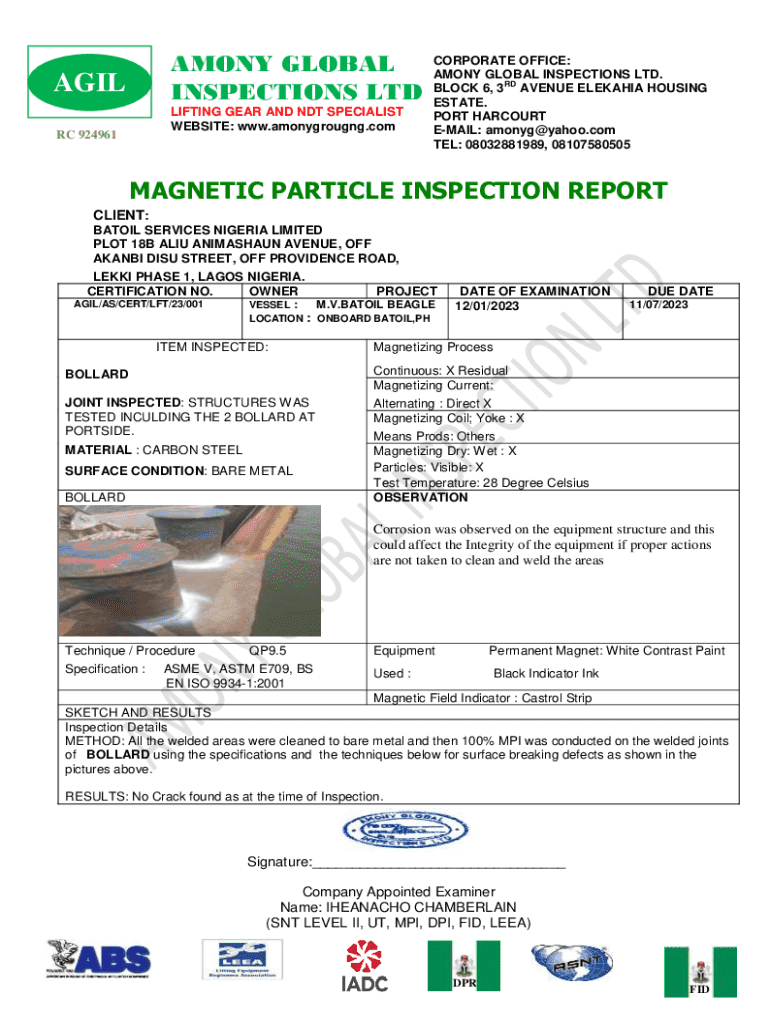

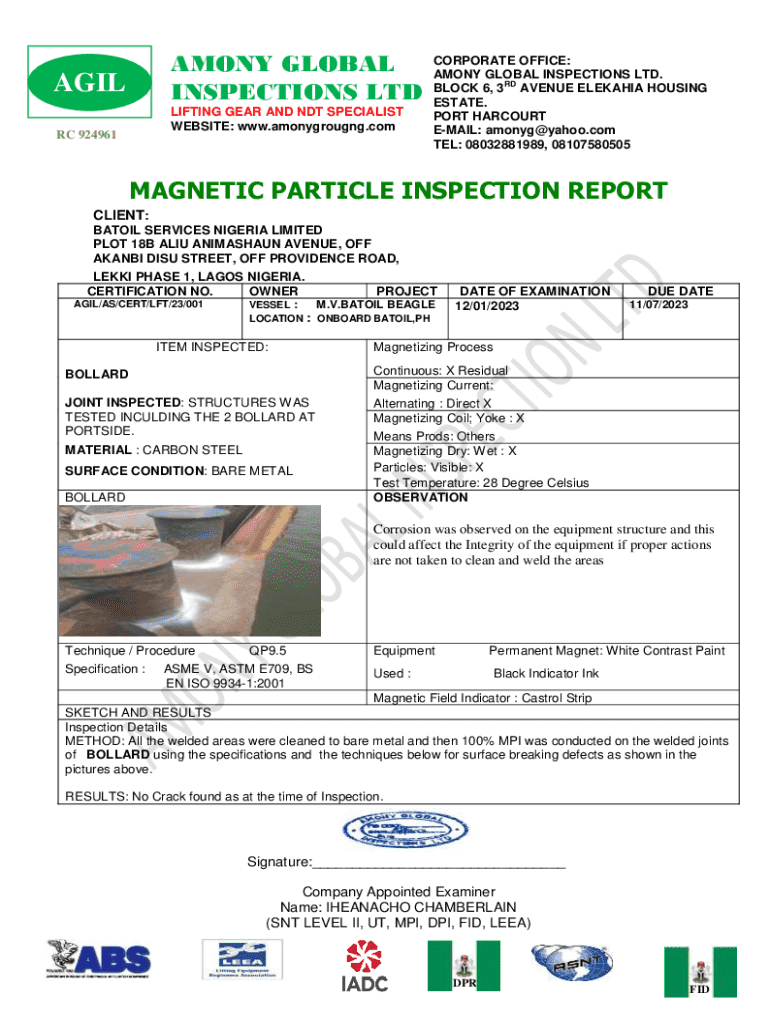

A magnetic particle inspection (MPI) report is a vital document used in non-destructive testing (NDT) to identify surface and near-surface defects in ferromagnetic materials. This report serves as a comprehensive summary of the inspection findings, procedures, and evaluations performed during inspection. The primary purpose of the MPI report is to provide documentation of these inspections for quality control and safety assurance, ensuring that components are compliant with industry standards.

The importance of magnetic particle inspection reports in NDT cannot be overstated. They play a crucial role in maintaining safety and reliability in various industries, such as aerospace, automotive, and manufacturing. By providing detailed documentation of inspection results, companies can make informed decisions regarding the usability and integrity of their components, thus minimizing the risk of failures and accidents.

Industries that heavily rely on MPI reports include aviation, automotive, structural engineering, and oil and gas. Each of these sectors demands rigorous testing to ensure that their equipment meets stringent safety regulations, and MPI reports are essential for maintaining compliance.

Key elements of a magnetic particle inspection report form

A well-structured magnetic particle inspection report form contains several critical sections that ensures thorough documentation of the inspection process. Here are the essential elements typically included in an MPI report:

A sample layout of a magnetic particle inspection report form would typically include fields for each of these sections, ensuring that all necessary information is captured systematically. This organized structure not only aids in clarity but also enhances compliance with industry regulations.

Advantages of using digital magnetic particle inspection reports

Utilizing digital magnetic particle inspection reports, especially through platforms like pdfFiller, offers numerous advantages that streamline the inspection reporting process. One primary benefit is accessibility; teams can access reports from anywhere, allowing for flexibility in operations and collaboration across locations.

When comparing traditional paper reports to digital formats, ease of editing and updating stands out as a significant advantage. Digital reports enable inspectors to quickly modify findings or procedures based on new information or feedback. Enhanced collaboration among teams is also a key benefit, allowing multiple stakeholders to contribute to and review inspection reports in real time, regardless of geographical barriers.

Moreover, integrating eSignature functions into digital reports streamlines the approval process, reducing the time spent in manual sign-offs. This feature not only ensures compliance with digital record-keeping requirements but also enhances the efficiency of the entire inspection process.

How to fill out a magnetic particle inspection report form

Filling out a magnetic particle inspection report form may seem daunting at first, but by following a structured approach, it can become a straightforward process. Here’s a step-by-step guide:

By following these steps, you can ensure that your magnetic particle inspection report is clear, professional, and compliant with industry standards.

Advanced features for managing reports on pdfFiller

pdfFiller offers advanced features that enhance the management of magnetic particle inspection reports. One key feature is the integration with other tools and software, allowing users to combine the power of different applications for a superior reporting experience.

Additionally, utilizing AI-enhanced capabilities can minimize human error when interpreting and inputting data. This not only ensures accuracy but also reduces the time spent on corrections, allowing teams to focus on analysis and decision-making.

Version control is another significant benefit offered by pdfFiller. This feature allows teams to track changes and collaborate in real time, providing a clear audit trail of all modifications made to the report. Such tracking is invaluable, especially during regulatory audits or inspections, where historical accuracy is essential.

Common challenges in magnetic particle inspection and report generation

Despite its benefits, magnetic particle inspection and the associated report generation can come with challenges. Common errors include incomplete data entry, misinterpretation of results, and inadequate documentation of inspection procedures. Therefore, understanding pitfalls is crucial for producing accurate reports.

One common solution is to implement detailed checklists during the inspection process. These can guide inspectors and ensure that no step is overlooked. Furthermore, educating all team members about the standards and procedures relevant to magnetic particle inspection can significantly reduce misinterpretations in report findings.

Additionally, technical difficulties may arise when utilizing software for report generation. Having a resource section within tools like pdfFiller can provide quick resolutions, allowing teams to troubleshoot issues efficiently.

Innovations in magnetic particle inspection reporting

Innovations in magnetic particle inspection technologies and reporting procedures are continually evolving. Upgraded materials within MPI techniques, such as improved magnetic fluids and particles, have enhanced the sensitivity and reliability of inspections. These advancements enable inspectors to detect even the smallest defects that could compromise safety.

Looking forward, software solutions are set to revolutionize how inspection reports are generated and analyzed. The use of AI in NDT is a particularly exciting trend that enhances accuracy and provides predictive analytics for identifying potential failures before they occur. This forward-thinking approach not only fosters safety but also optimizes operational efficiency.

Related forms and templates available on pdfFiller

pdfFiller hosts a variety of related forms and inspection report templates, catering to different industries and needs. Accessing and utilizing these templates can help streamline processes, ensuring your reports adhere to expected standards and formats.

Users can customize these templates based on their unique requirements. This flexibility allows for adaptations in varying contexts, whether you’re in aerospace, construction, or automotive fields. Moreover, free resources and tools provided by pdfFiller empower users to manage their documents effectively and maintain compliance.

Frequently asked questions about magnetic particle inspection reports

Turning to frequently asked questions can clarify common queries about magnetic particle inspection reports. One common question is how long should the inspection records be retained? Regulatory bodies typically require these documents to be kept for a specified period, often ranging from three to seven years, but it’s essential to consult specific industry guidelines.

Another query pertains to the qualifications needed to perform MPI and interpret results. Generally, inspectors must possess certifications in NDT techniques, which often include specific training and practical experience to ensure reliability in their findings.

For new users navigating NDT tools, leveraging resources available on pdfFiller can offer a crucial starting point. These resources can also clarify regulations and compliance standards relevant to MPI reports, ensuring users are well-informed and prepared.

Best practices for follow-up after completing a magnetic particle inspection report

After completing a magnetic particle inspection report, it is essential to communicate findings effectively with all relevant stakeholders. Sharing results promptly allows for timely decision-making and reinforces safety protocols within the organization.

Setting up reminders for further inspections is another key practice. This proactive approach helps ensure that components are regularly monitored, promoting safety and reliability. Additionally, implementing document retention policies will help your organization remain compliant with industry regulations and maintain a clear record of inspections performed.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for signing my magnetic particle inspection report in Gmail?

Can I edit magnetic particle inspection report on an Android device?

How do I fill out magnetic particle inspection report on an Android device?

What is magnetic particle inspection report?

Who is required to file magnetic particle inspection report?

How to fill out magnetic particle inspection report?

What is the purpose of magnetic particle inspection report?

What information must be reported on magnetic particle inspection report?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.