Get the free pdffiller

Get, Create, Make and Sign pdffiller form

Editing pdffiller form online

Uncompromising security for your PDF editing and eSignature needs

How to fill out pdffiller form

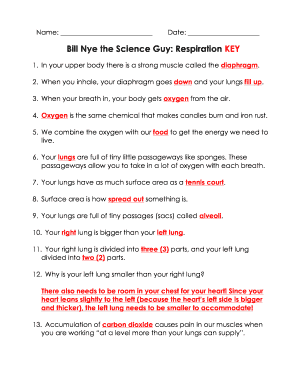

How to fill out construction quality control checklist

Who needs construction quality control checklist?

Construction Quality Control Checklist Form: Your Comprehensive Guide

Understanding quality control in construction

Quality Control (QC) in construction involves systematic processes aimed at ensuring that the constructed product meets predefined quality standards and satisfies client expectations. It encompasses a range of inspections, testing procedures, and corrective actions to maintain quality throughout the construction phases. Effective QC is not just a safety or compliance issue; it is crucial for delivering durable and reliable structures.

The importance of QC in construction projects stems from the significant repercussions of construction defects, which can lead to project delays, costly repairs, and compromised safety. By implementing regular quality checks, contractors can identify issues early, thereby mitigating risks and ensuring that project deadlines are met without sacrificing quality.

Checklists play an essential role in this process, providing a clear framework for assessing various aspects of the construction work. They serve as critical tools for documentation and communication, ensuring that all team members are aligned on quality standards and expectations.

Benefits of using construction quality control checklists

Utilizing construction quality control checklists brings numerous advantages to construction projects. The foremost benefit is enhanced consistency and reliability in the quality of the work performed. With a checklist, inspectors can verify that every critical quality component has been addressed before moving forward. This structured approach reduces variability and helps uphold standards across different teams and projects.

Moreover, effective checklists improve communication among various teams by providing a standardized reference point. When everyone on the team shares an understanding of what needs to be checked, it minimizes misunderstandings and ensures that each quality aspect is considered.

In addition, these checklists aid in risk management and compliance assurance. By conducting thorough inspections, project teams can identify potential hazards or issues before they escalate, ensuring that all construction adheres to regulations. This proactive approach not only protects the project’s integrity but also safeguards stakeholders.

Lastly, structured quality control leads to significant time and cost savings throughout the project life cycle. With a clear checklist guiding the inspection and quality assurance processes, teams can minimize rework and expedite completion timelines, ultimately saving money and resources for the project.

Key components of a quality control checklist

A well-rounded construction quality control checklist comprises several essential elements, tailored to the specific requirements of each project. The essential components typically include sections dedicated to safety, materials, workmanship, and documentation. Each category requires distinct inspection points to focus on, ensuring comprehensive coverage.

Creating sections that address safety measures helps confirm compliance with regulations, while material inspections verify that the products used meet quality standards. Workmanship checks assess the quality and precision of the job performed. Additionally, a documentation section ensures all completed inspections and findings are recorded properly, enabling accountability and traceability.

Customizability is critical; checklists should be adapted to reflect the specific requirements of different projects, whether they are residential, commercial, or industrial in nature. This flexibility enables project managers to cater the form to the challenges unique to their construction environments.

How to create a construction quality control checklist

Creating an effective construction quality control checklist requires a strategic approach. Start by identifying the project scope and the specific requirements associated with it. Understanding the detailed aspects of the project helps inform the key inspection points that need inclusion in the checklist.

Next, outline the critical inspection points that need to be verified during the construction process. Collaborate with project stakeholders to gather their input and insights, ensuring that all critical areas are captured. This collaborative process fosters ownership and commitment to quality among the team members.

Once you have defined the key points, format the checklist for ease of use. It should be logically structured, user-friendly, and accessible to all team members involved in the inspection processes. Consider utilizing digital solutions to streamline the creation process.

Tools and software, such as pdfFiller, can enhance the effectiveness of checklist creation by enabling easy editing, eSigning, and team collaboration. The platform offers templates for customizing checklists, ensuring all team members can conveniently access and modify documents.

Ready-to-use quality control checklists

Having a set of ready-to-use quality control checklists can significantly streamline the construction process. For example, a pre-construction checklist might include items such as site preparation protocols, permit verifications, and initial safety briefings. This ensures that all components are in place before the physical work begins.

An in-process quality control checklist can cover crucial areas such as material inspections, structural and mechanical checks, and compliance with safety standards during active construction. Maintaining this checklist throughout the process helps identify and rectify issues in real-time, enhancing the overall quality.

Finally, a post-construction or final inspection checklist can be invaluable. Checkpoints might include safety checks, final documentation, commissioning procedures, and client walk-throughs. These components help ensure that nothing is overlooked when finalizing the project, leading to a successful handover.

Implementing the construction quality control checklist

The successful implementation of your construction quality control checklist hinges on comprehensive training for your team on how to use it effectively. Ensure that all relevant parties understand the importance of the checklist and how to conduct inspections based on it. Offer workshops or seminars focusing on practical applications and common pitfalls to avoid.

Integrating checklists into workflow and daily inspections is essential. Make these checklists a routine part of the construction process, integrating them into meetings, discussions, or reporting formats to reinforce their importance. Regular reviews of the checklist amidst ongoing work can facilitate continued awareness and focus on quality.

Finally, ensure a system for continuous improvement based on feedback and results from checklist implementation. Invest time in discussing what works well and what areas can be improved with your team, fostering a culture of quality within the organization.

Technology and tools in quality control

Technology plays a pivotal role in enhancing quality control in construction. Tools such as pdfFiller provide a streamlined solution for document creation and management, making it easier for teams to edit PDFs, eSign, and collaborate on documents directly within a cloud-based platform. This means that updates can be made quickly, enabling team members to access the most current information easily.

In addition to pdfFiller, several other software solutions can benefit construction quality control, offering features like real-time collaboration, reporting capabilities, and mobile applications for inspections. A digital checklist often provides seamless real-time data entry and tracking, which can help teams stay vigilant about quality through instant updates.

When comparing digital and traditional checklists, digital platforms typically fare better due to their convenience, accessibility, and the ability to collect data efficiently. Transitioning to modern solutions can provide a significant advantage, particularly for larger projects that involve complex coordination across various teams.

Case studies: successful quality control implementation

Many construction projects have successfully implemented quality control checklists, showcasing the effectiveness of this method. For instance, a notable commercial development in Chicago employed a comprehensive QC checklist that encompassed all phases, leading to a 20% reduction in defects during the construction phase. Teams used the checklist to systematically inspect critical areas, ensuring that standards were met consistently.

However, challenges often arise during implementation. One project faced resistance from the teams unfamiliar with the new QC process, causing delays. To mitigate this, leadership organized training sessions emphasizing the checklist's benefits, which increased buy-in and understanding among team members. The measurable outcome highlighted a decrease in rework and improved completion timelines, proving that an upfront investment in training pays off.

Common pitfalls in quality control processes

While establishing a quality control checklist is a crucial step, several common pitfalls can undermine its effectiveness. One significant issue arises from inadequate checklist creation, often resulting in missing key inspection points. Teams must ensure that checklists are comprehensive and specifically tailored to the project.

Another common challenge is the lack of follow-up on issues raised during inspections. Without a mechanism to address discovered problems, organizations may find themselves facing recurring challenges. Therefore, assigning responsibility for rectifying identified issues is essential. Additionally, resistance to change in team practices can hinder the adoption of the checklist, leading to ineffective use. Building a collaborative environment where team members feel part of the process can alleviate this resistance.

Expert insights on construction quality control

Insights from industry professionals reveal that staying ahead in quality management is crucial for successful construction projects. Gathering varying viewpoints from quality control experts can provide valuable advice on best practices, such as regularly updating checklists based on lessons learned from previous projects. They often recommend periodic training and check-ins to reinforce quality standards consistently.

Looking toward the future, trends in construction quality assurance hint at an increasing reliance on technology and automation. As the construction landscape evolves, utilizing data analytics and artificial intelligence to support quality checks will become indispensable. Embracing these changes early can set companies apart, leveraging modern solutions for enhanced oversight and management.

Frequently asked questions (FAQs)

One of the frequently asked questions about the construction quality control checklist is its primary purpose. The checklist serves to provide a structured approach to ensuring that quality standards are met while documenting inspections. This is critical for accountability and tracing back any issues that arise.

Another common inquiry is about how often the checklist should be updated. Regular reviews are necessary, especially following completed projects or when new standards or materials emerge. Lastly, many wonder whether the checklist can be shared across different project teams. The answer is yes, a well-formulated checklist can serve multiple teams across various projects, promoting consistency in quality control efforts.

Exploring other available checklists

The construction industry offers a wealth of specialized checklists tailored to diverse sectors, such as residential, commercial, industrial, and safety-related construction. Accessing a library of customizable templates can significantly ease the burden on teams looking to establish or enhance their quality control processes. These templates can be modified to suit specific project needs, accommodating the unique challenges of each sector.

Resources for further learning

As the field of quality control continues to evolve, various resources can enhance understanding and inform best practices. Links to comprehensive quality control guides, industry seminars, and training programs offer invaluable information that can empower construction professionals. Recommended reads include books and articles that delve deeper into construction management and quality assurance principles, providing readers with a solid foundation for their careers.

Newsletter signup and updates

Subscribing to industry newsletters ensures that you stay informed about emerging trends, changes in regulations, and advancements in construction quality management. Accessing new templates and tools through these updates can help your organization remain compliant and optimize quality control practices over time.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send pdffiller form for eSignature?

How can I edit pdffiller form on a smartphone?

How do I complete pdffiller form on an iOS device?

What is construction quality control checklist?

Who is required to file construction quality control checklist?

How to fill out construction quality control checklist?

What is the purpose of construction quality control checklist?

What information must be reported on construction quality control checklist?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.