Get the free Burndy 172 standard weld metal-np starting powder.xls

Show details

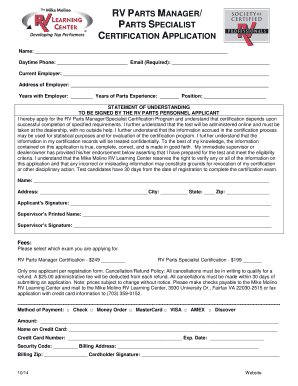

MATERIAL SAFETY DATA SHEET HIS HAZARD RATINGS OSHA Meets 29 CFR 1910.1200 Standards HEALTH FLAMMABILITY PHYSICAL HAZARD * Chronic Health Hazard 0 INSIGNIFICANT 1 SLIGHT 1 0 0 2 MODERATE 3 HIGH 4 EXTREME

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign burndy 172 standard weld

Edit your burndy 172 standard weld form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your burndy 172 standard weld form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit burndy 172 standard weld online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Log in to account. Start Free Trial and sign up a profile if you don't have one yet.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit burndy 172 standard weld. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out burndy 172 standard weld

How to fill out burndy 172 standard weld:

01

Start by ensuring that you have all the necessary materials and equipment for the welding process, such as the burndy 172 standard weld tool, metal connectors, electrical cables, protective gear, and a power source.

02

Before starting, make sure to read and understand the instructions and safety guidelines provided by the manufacturer. Familiarize yourself with the specific requirements for using the burndy 172 standard weld tool.

03

Prepare the surfaces that need to be welded. Clean the metal connectors thoroughly to remove any dirt, rust, or debris. Use the appropriate tools, such as wire brushes or sandpaper, to achieve a clean and smooth surface.

04

Position the metal connectors in the desired configuration and secure them in place. Follow the recommended spacing and alignment guidelines provided by the manufacturer to ensure proper welding.

05

Connect the burndy 172 standard weld tool to a suitable power source, following the provided electrical specifications. Make sure to follow all safety precautions when dealing with electricity.

06

Turn on the power to the burndy 172 standard weld tool and allow it to heat up according to the recommended time specified by the manufacturer.

07

Once the weld tool is properly heated, place the tool onto the metal connectors. Apply uniform pressure to ensure a secure connection between the connectors and the weld tool.

08

Hold the tool in place for the required welding time. The duration may vary depending on the size and type of the metal connectors. Refer to the user manual for the recommended welding time.

09

After the welding process is complete, carefully remove the burndy 172 standard weld tool from the metal connectors. Allow the weld joint to cool down before further handling.

10

Inspect the welded joint to ensure it meets the required quality standards. Check for any signs of defects, such as incomplete fusion or cracks. If any issues are found, consult the manufacturer's guidelines for troubleshooting or seek professional assistance.

Who needs burndy 172 standard weld?

01

Electrical contractors: The burndy 172 standard weld is commonly used in electrical installations and repairs, making it an essential tool for professionals working in this field.

02

Industrial manufacturers: Industries that require secure and durable electrical connections, such as manufacturing plants, often rely on the burndy 172 standard weld for their electrical connections.

03

Construction professionals: From building new structures to renovating existing ones, construction workers often need the burndy 172 standard weld to ensure the safety and reliability of electrical connections in various construction projects.

04

Maintenance technicians: Technicians responsible for the maintenance and repair of electrical systems may need the burndy 172 standard weld to quickly and effectively make or repair electrical connections.

05

DIY enthusiasts: Individuals who enjoy DIY projects and need to make electrical connections at home or for personal projects can benefit from using the burndy 172 standard weld as it provides a secure and long-lasting connection.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is burndy 172 standard weld?

Burndy 172 standard weld is a type of standardized welding process used in electrical connections.

Who is required to file burndy 172 standard weld?

Electricians and contractors who perform electrical connections are required to file burndy 172 standard welds.

How to fill out burndy 172 standard weld?

To fill out burndy 172 standard weld, one must provide information on the materials used, the welding process, and any testing that was conducted.

What is the purpose of burndy 172 standard weld?

The purpose of burndy 172 standard weld is to ensure that electrical connections are made safely and securely.

What information must be reported on burndy 172 standard weld?

Information on the materials used, welding process, and testing results must be reported on burndy 172 standard weld.

How can I modify burndy 172 standard weld without leaving Google Drive?

pdfFiller and Google Docs can be used together to make your documents easier to work with and to make fillable forms right in your Google Drive. The integration will let you make, change, and sign documents, like burndy 172 standard weld, without leaving Google Drive. Add pdfFiller's features to Google Drive, and you'll be able to do more with your paperwork on any internet-connected device.

How do I complete burndy 172 standard weld online?

pdfFiller has made filling out and eSigning burndy 172 standard weld easy. The solution is equipped with a set of features that enable you to edit and rearrange PDF content, add fillable fields, and eSign the document. Start a free trial to explore all the capabilities of pdfFiller, the ultimate document editing solution.

How can I edit burndy 172 standard weld on a smartphone?

The pdfFiller mobile applications for iOS and Android are the easiest way to edit documents on the go. You may get them from the Apple Store and Google Play. More info about the applications here. Install and log in to edit burndy 172 standard weld.

Fill out your burndy 172 standard weld online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Burndy 172 Standard Weld is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.