Get the free Nomex Fiber Packing

Get, Create, Make and Sign nomex fiber packing

How to edit nomex fiber packing online

Uncompromising security for your PDF editing and eSignature needs

How to fill out nomex fiber packing

How to fill out nomex fiber packing

Who needs nomex fiber packing?

Understanding Nomex Fiber Packing Form: A Comprehensive Guide

Overview of Nomex fiber packing

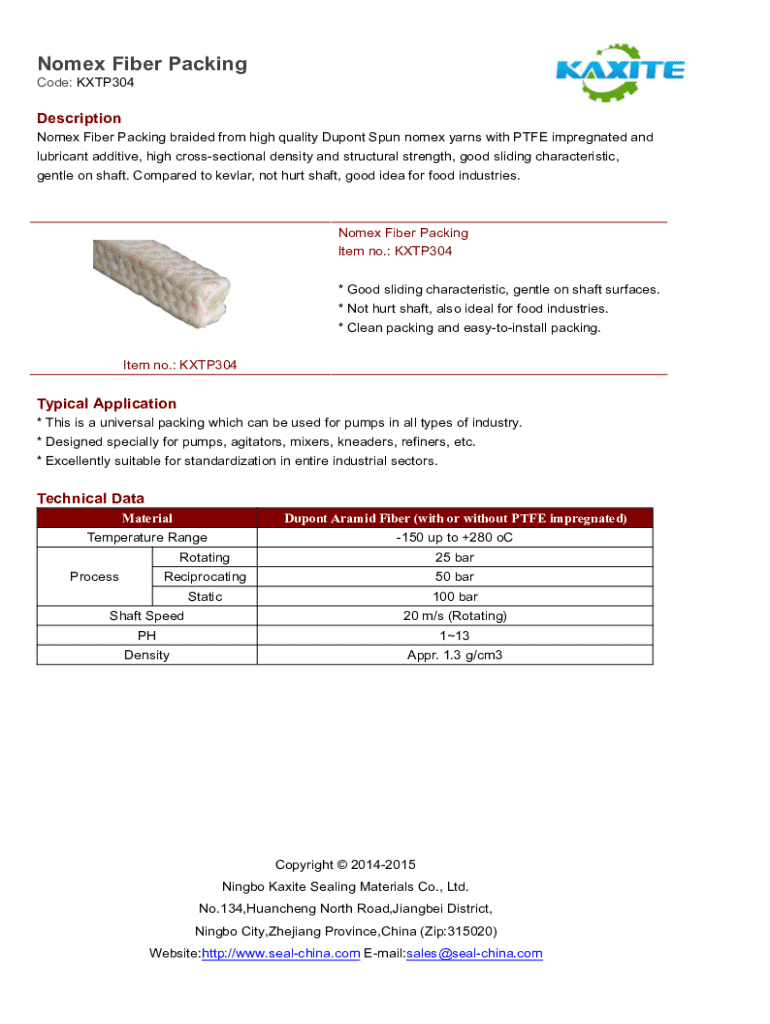

Nomex fiber packing is a high-performance material made from synthetic aramid fibers, known for its exceptional thermal and chemical resistance. Developed by DuPont, Nomex is primarily utilized in high-temperature applications requiring insulation and operational efficiency, which makes it ideal for packing solutions in demanding industrial environments. Its unique molecular structure provides strength, rigidity, and an impressive ability to retain its properties under extreme heat and pressure.

Key characteristics such as thermal stability and flame retardant properties make Nomex fiber packing a preferred choice in sectors where material failure can lead to catastrophic events. This packing is not only robust but also lightweight, translating into easier installation and operation.

Applications of Nomex fiber packing

Nomex fiber packing boasts versatile applications across various industries. Its fire-resistant properties make it suitable for aerospace, automotive, and chemical processing, where high-performance sealing solutions are needed. In aerospace, for instance, Nomex fiber packing is used in engine components to manage heat under extreme conditions, while in the automotive sector, it is employed in sealing gaskets that keep engines optimized and efficient. This adaptability is also pivotal in chemical processing, where valves and pumps utilize Nomex to provide reliable seals even when exposed to corrosive substances.

Commercially, HVAC systems benefit from Nomex fiber packing to ensure that air flow is maintained and heat retention is optimized. Similarly, fluid handling systems leverage Nomex materials to guarantee that seals remain intact under different pressures and temperatures, ensuring safe and efficient operation.

Benefits of using Nomex fiber packing

One of the key advantages of Nomex fiber packing is its versatility, allowing it to perform in various demanding environments without compromising integrity. Its exceptional thermal stability ensures that it maintains performance even in conditions that would typically degrade other materials. Consequently, equipment longevity is significantly improved, resulting in fewer replacements and a greater return on investments.

Moreover, using Nomex fiber packing can lead to reduced maintenance costs. As this material is designed to withstand extensive wear, the frequency of maintenance checks and parts replacements decreases. This reliability contributes to overall operational efficiency—enabling businesses to allocate resources more effectively.

Comparing Nomex fiber packing to other materials

When assessing Nomex fiber packing, it's essential to understand how it compares to other common packing materials, such as aramid fiber packing and polytetrafluoroethylene (PTFE) + aramid packing. While aramid packing offers some heat resistance, it typically doesn't match Nomex's thermal stability or chemical resistance, making Nomex the better choice for high-stakes applications.

PTFE + aramid packing combines the properties of PTFE's low friction and high chemical resistance with the high strength and durability of aramid fibers. However, while it may be practically effective, Nomex packing generally performs better in extreme temperature scenarios, even though it might come with a higher initial cost. GPTFE + aramid packing addresses specific needs for applications requiring both low friction and high strength, but it has limitations regarding high-temperature environments, where Nomex packing excels.

Understanding the Nomex fiber packing form

The Nomex fiber packing form is a crucial document that standardizes the information required for the proper specification and installation of Nomex fiber packing. It encompasses various sections, each catering to specific needs that help teams ensure consistent application across different projects. The structure includes personal information, specifications, and installation guidelines to provide clarity and ease of use.

The personal information section is vital for identifying the user and project details, ensuring clear communication throughout the process. Specifications and requirements detail the necessary dimensions, performance expectations, and conditions under which the packing is to be installed. Lastly, the installation guidelines offer crucial insights on how to effectively utilize Nomex fiber packing, thereby enhancing efficiency and reducing errors.

How to fill out the Nomex fiber packing form

Filling out the Nomex fiber packing form is a vital task that requires attention to detail to ensure accuracy and completeness. Follow these step-by-step instructions to ensure your form is properly filled out:

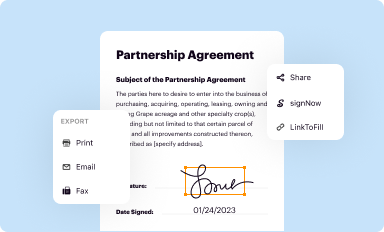

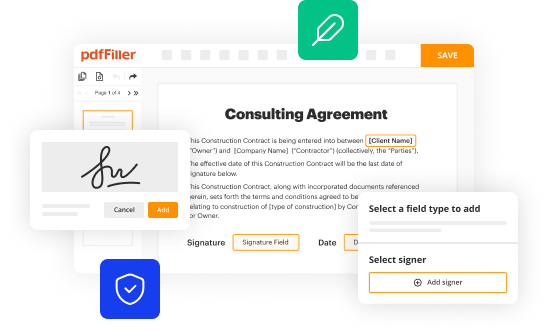

To ease the process further, you can leverage interactive tools available on pdfFiller. Utilize editing features that allow you to fill in the form digitally, sign electronically, and share with team members instantly.

Managing your Nomex fiber packing documents

Managing documents related to Nomex fiber packing can greatly enhance efficiency for teams. Utilizing pdfFiller's platform allows users to save and organize forms conveniently, ensuring you can access necessary documents from anywhere, anytime.

Collaborative features on the platform allow teams to work together seamlessly, combining efforts in real-time. This is crucial when completing complex projects that require multiple inputs. Additionally, version control for document revisions ensures that everyone is working from the most up-to-date information, minimizing the risk of errors due to outdated documentation.

Expert recommendations

Expert recommendations for using Nomex fiber packing highlight best practices that can lead to optimal performance. Firstly, it is essential to ensure that the packing is compatible with the specific application and environment it will be subjected to, thus minimizing the risk of premature failure.

Common mistakes to avoid include overlooking installation guidelines, which can lead to improper sealing and operational inefficiencies. Additionally, selecting the right material based on specific application needs is critical; factors such as temperature, pressure, and chemical exposure must all be carefully considered together.

Case studies and success stories

Numerous case studies showcase the utility of Nomex fiber packing in real-world applications. For example, an aerospace company found that replacing traditional packing with Nomex in their engines resulted in a 30% increase in efficiency due to better thermal management. Similarly, a chemical processing plant noted how shifting to Nomex packing led to significant reductions in maintenance downtime, translating into improved productivity.

Testimonials from industry leaders emphasize the reliability and performance of Nomex fiber packing. Many have praised its ability to survive under extreme conditions, yielding a substantial cost benefit over time as maintenance and replacement needs were drastically reduced.

Frequently asked questions (FAQs)

Common inquiries about Nomex fiber packing often center around its applications and maintenance. Users frequently ask about the temperature limits for various applications, with a recommendation to adhere to 400°C (752°F) for optimal performance. Additionally, customers may experience challenges when filling out the Nomex fiber packing form, often regarding specific specifications or installation guidelines.

To streamline the process, users should consult available resources for assistance, including guides on common troubleshooting issues. Tips for effective follow-up and updates on projects are also encouraged to ensure continuous improvement.

Related products and services

When considering Nomex fiber packing, it's important to explore related products and services that can enhance overall performance. Other packing materials, such as PTFE and GPTFE, offer specific advantages in different applications, bridging gaps where Nomex might not be suitable due to cost or specific environmental conditions.

Unimax, a leading provider in the market, offers a range of packing solutions tailored to various needs, including customized options for unique applications. Users can also access comprehensive user guides that provide valuable insights into optimizing their packing choices and installation processes.

Quick links and contact information

For further assistance and to access additional resources related to Nomex fiber packing, users can explore links provided on the pdfFiller platform. Direct contact options for customer support ensure that any questions can be promptly addressed, while subscribing to updates keeps users informed about the latest advancements and offerings in packing materials.

Innovations and latest developments in Nomex technology

Innovations in material science continually influence the development of Nomex fiber packing. Emerging trends, such as the integration of nanotechnology, seek to enhance the fiber's thermal and mechanical properties further. Innovations within the industry aim to reduce production costs while maintaining high-performance standards, broadening Nomex's scope of applications.

Looking ahead, the market forecasts an increase in demand for Nomex-based solutions in industries focused on energy efficiency and sustainability. These advancements will continue to bolster its reputation as one of the leading choices for high-performance packing materials.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my nomex fiber packing directly from Gmail?

How do I edit nomex fiber packing in Chrome?

Can I sign the nomex fiber packing electronically in Chrome?

What is nomex fiber packing?

Who is required to file nomex fiber packing?

How to fill out nomex fiber packing?

What is the purpose of nomex fiber packing?

What information must be reported on nomex fiber packing?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.