Get the free Cooler Temperature Log

Get, Create, Make and Sign cooler temperature log

Editing cooler temperature log online

Uncompromising security for your PDF editing and eSignature needs

How to fill out cooler temperature log

How to fill out cooler temperature log

Who needs cooler temperature log?

Cooler Temperature Log Form: A Comprehensive Guide

Understanding the cooler temperature log form

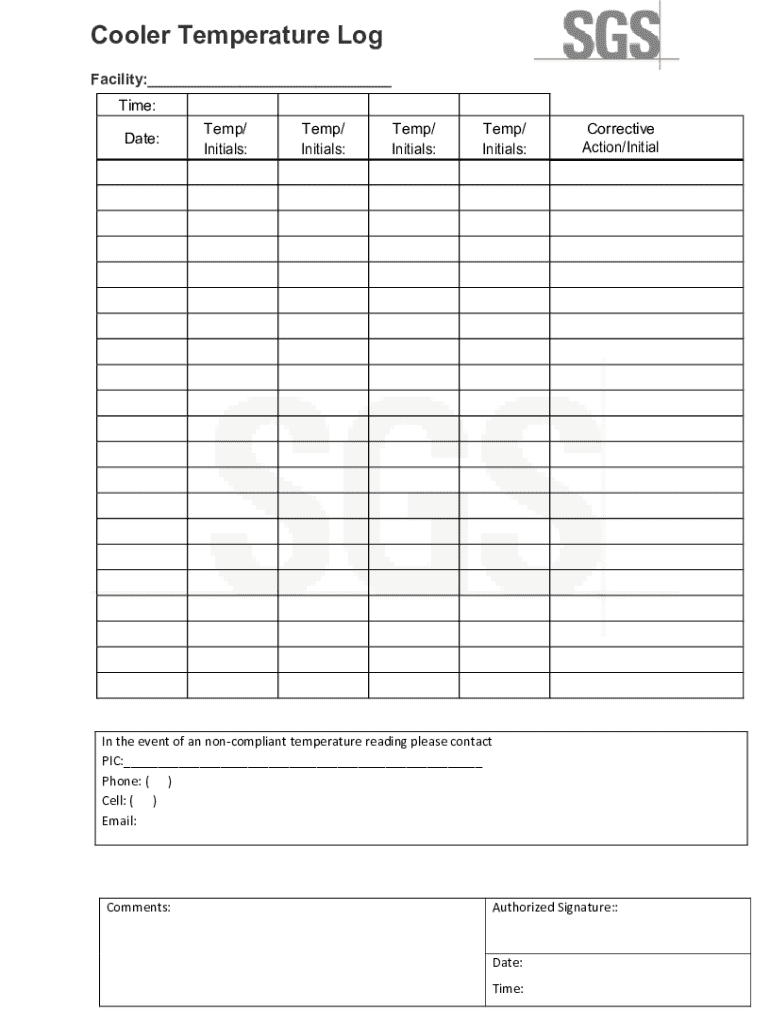

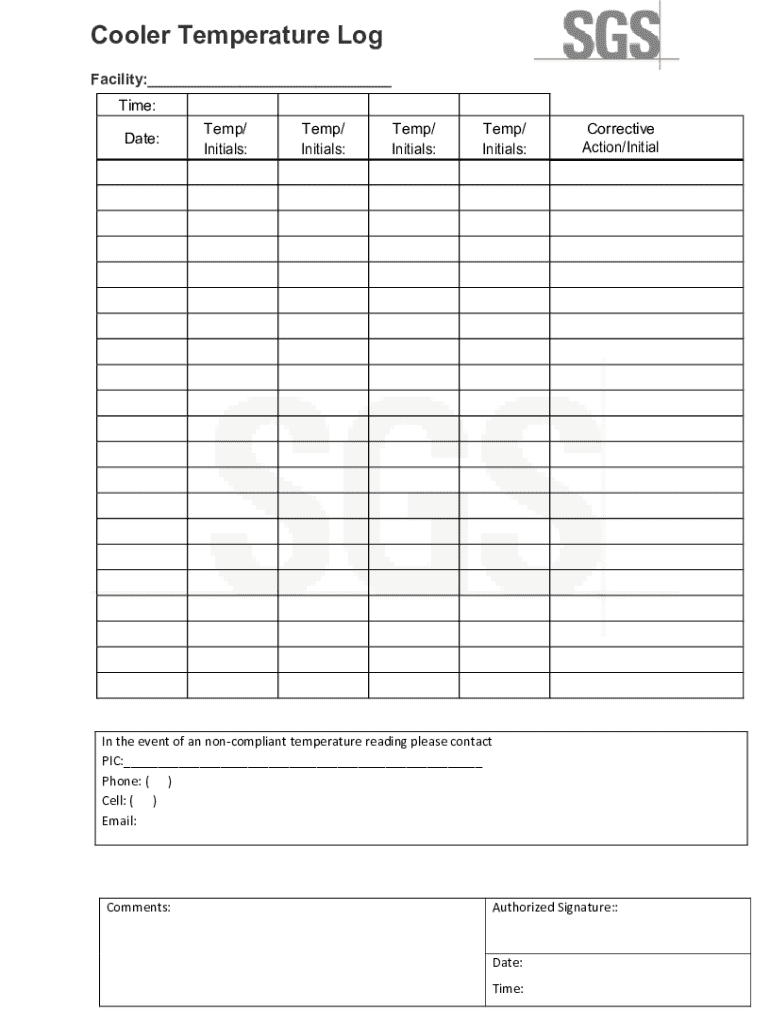

A cooler temperature log form is a systematic documentation tool utilized to record temperature readings for items stored in coolers and refrigerators. Its primary purpose revolves around maintaining the appropriate storage conditions for perishable items, ensuring their safety and quality. This form not only captures essential data but also emphasizes accountability and compliance with health guidelines.

The benefits of using a cooler temperature log include minimizing food spoilage, enhancing safety standards, and providing a clear audit trail for regulatory compliance. By accurately logging temperatures, organizations can swiftly identify deviations and make informed decisions to avert potential hazards. Moreover, such records can serve as critical proof during inspections.

Common applications of the cooler temperature log can be found across various industries, notably in the food service sector, healthcare facilities, or any business dealing with temperature-sensitive products. Each application demands accuracy and regular monitoring to ensure adherence to safety standards.

Importance of accurate temperature logging

Accurate temperature logging is pivotal in diverse sectors, especially for ensuring food safety compliance. Foodborne illnesses can stem from improper temperature control; hence consistent logging is vital in identifying if food products remain within the safe temperature range. This endeavor directly impacts customer health and business reputation.

Furthermore, maintaining the integrity of products is crucial for manufacturers and retailers. Inadequate temperature control can compromise the safety and efficacy of pharmaceutical products, resulting in financial losses and damaging consumer trust. Not adhering to strict logging protocols can also lead to penalties from health inspectors.

Legal implications are also critical; many industries require documentation supporting the maintenance of ideal storage conditions over a specified period. Failure to keep accurate records may expose businesses to liability in the event of health-related incidents.

Components of a cooler temperature log form

For effective logging, a cooler temperature log form must include several essential fields. Date and time of logging provide a timeline that can be referred back to if discrepancies arise. Item descriptions enable users to track which products require specific temperatures, preventing any mix-ups during audits.

Temperature readings should be clearly recorded to facilitate easy analysis. Finally, including the name of the personnel responsible for completing the log promotes accountability and enables cross-checking if questions about the data arise.

Optional add-ons can also enhance tracking capabilities. Documenting the cooler's location can help in large facilities where multiple units are used. Moreover, including maintenance or inspection notes can be invaluable during audits, flagging any potential issues before they escalate.

Step-by-step instructions for filling out the cooler temperature log

The process of using a cooler temperature log begins with preparation. Ensure you have all necessary equipment at hand, particularly accurate thermometers, pens, and the log form itself. Familiarize yourself with your specific cooler's monitoring needs and temperature ranges, as using the right tool is essential for accurate assessments.

Next is recording the temperature readings. Best practices dictate that each reading should be taken from different locations within the cooler to ensure even temperature distribution. Avoid opening the cooler frequently to minimize temperature fluctuations that can affect accuracy.

Finally, completing the log form requires careful data entry. For paper logs, write legibly and ensure all the relevant fields are filled out. If using digital formats, platforms like pdfFiller allow for smooth editing and signing, making the entire process quicker and more efficient. Be consistent—the uniformity of data is crucial for monitoring trends and identifying issues over time.

Best practices for maintaining cooler temperature logs

Consistency in logging schedules is paramount. Establishing regular intervals for recording temperatures enables the formation of reliable data patterns, which can highlight trends and deviations. This practice not only promotes punctuality but also instills a habit of diligence in staff. Regular training sessions can reinforce the importance of logging and encourage engagement with the process.

When dealing with temperature deviations, swift action is required. If a temperature outside the safe range is noticed, immediate documentation and corrective action must be taken to address the issue. This can include adjusting cooler settings, removing affected products, or conducting thorough inspections.

Establishing review processes is also advisable. Regular checks not only maintain the quality of logged data but also ensure adherence to protocols. Organizations that prioritize audits are more likely to identify systemic issues and correct them proactively.

Utilizing technology for efficient temperature logging

The advent of digital technology offers numerous advantages for cooler temperature logging. Digital forms and cloud-based solutions provide accessibility and convenience, enabling users to log temperatures from any location effortlessly. This flexibility is particularly beneficial for teams operating in multiple sites, as centralized data collection becomes feasible.

With platforms like pdfFiller, users can leverage interactive tools for easy editing and eSigning. Such features minimize paperwork and streamline document management, allowing for quick adjustments and improved accuracy with data entries. Enhanced collaboration becomes possible, as team members can work together seamlessly to ensure compliance.

Using technology not only simplifies the logging process but also enhances the reliability of collected data, thus fostering a culture of precision and accountability.

Common mistakes to avoid when using a cooler temperature log

One significant pitfall is inadequate training for staff. It’s essential that team members are well-informed about how to use the cooler temperature log accurately. Without proper guidance, errors can occur, undermining the log's effectiveness. Regular training and refreshers can mitigate this risk.

Another frequent mistake is delaying record updates. Timeliness is critical; logs should be filled out immediately after temperature checks to maintain accuracy. Lastly, neglecting to back up digital logs can lead to a loss of critical data. Establishing a routine for safeguarding these records is fundamental to ensuring that data remains accessible.

Being aware of these common mistakes and addressing them systematically can lead to a more effective temperature logging process, ultimately strengthening operational integrity and compliance.

Real-world case studies

Real-world examples illustrate the impact of rigorous temperature logging. For instance, a restaurant chain that meticulously implemented updated cooler temperature logs observed a significant decline in food safety violations over the course of a year. By establishing a standardized logging process and retraining their team, they ensured compliance with health code regulations and improved overall operational efficiency.

In another case, a pharmaceutical company faced integrity issues with its temperature-sensitive products. By adopting a digital cooler temperature log form, they improved monitoring of their shipment and storage processes, which not only conformed to regulations but also enhanced customer trust in their product efficacy.

These cases serve as reminders that maintaining accurate cooler temperature logs is not merely a best practice but a critical component of operational success in temperature-dependent industries.

Frequently asked questions (FAQs)

When it comes to cooler temperature logs, many users have questions regarding best practices. One common inquiry is about the recommended frequency for logging temperatures. Typically, most guidelines suggest logging temperatures at least every four hours; however, more frequent checks might be necessary depending on the type of products being stored.

Another frequently raised question is whether mobile devices can be used for recording temperatures. The answer is a definitive yes, particularly if you leverage applications designed for temperature logging. Many solutions, including pdfFiller, enable logging on mobile platforms for convenience and accessibility.

Lastly, retaining logs for compliance purposes can be daunting. Generally, logs should be retained for at least one year, but this can vary by local regulations. Always verify your area's requirements to ensure you remain compliant.

Final tips for effective cooler temperature management

Creating a culture of accountability within the workplace can radically transform how temperature logs are perceived and utilized. Encourage team members to take ownership of their logging responsibilities by setting clear expectations and reinforcing their importance regularly. Recognizing diligent efforts can also motivate staff to maintain rigorous standards.

Continually improving processes through ongoing training sessions nurtures knowledge retention among your staff. Collecting feedback regarding the usability of logs may uncover areas for enhancement, thus refining your approach to temperature management. By leveraging analytics from logged data, businesses can identify trends and areas for operational efficiencies, ultimately translating into enhanced profitability and reduced waste.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an eSignature for the cooler temperature log in Gmail?

How do I fill out cooler temperature log using my mobile device?

How do I complete cooler temperature log on an iOS device?

What is cooler temperature log?

Who is required to file cooler temperature log?

How to fill out cooler temperature log?

What is the purpose of cooler temperature log?

What information must be reported on cooler temperature log?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.