Work Order Process Checklist Form: A Comprehensive Guide

Understanding work orders

A work order serves as a crucial communication tool within organizations, detailing tasks that need to be completed. Its primary purpose is to streamline operations, ensuring all team members are informed about ongoing and upcoming projects. By providing clarity on responsibilities and expectations, work orders minimize misunderstandings and enhance productivity. Companies across various sectors, including construction, manufacturing, IT services, and facilities management, are increasingly relying on effective work order processes to allocate resources efficiently and manage workflows seamlessly.

Construction: Using work orders to schedule and record progress on projects.

IT Service Management: Creating task-oriented work orders to address user requests and issues.

Manufacturing: Implementing work orders for machine maintenance and product assembly.

Facility Management: Handling maintenance and repair tasks efficiently.

Key elements of a work order

The effectiveness of a work order largely depends on its components. Essential elements include a clearly defined title and description, providing context for the task. The requestor's information, including their role and contact details, ensures accountability and facilitates follow-ups. Additionally, task details, such as the nature and location of the work, should be specified alongside the priority level to help teams address urgent requests promptly. Finally, assignment information indicates who is responsible for completing the work, thus clarifying ownership.

Title and Description: A concise overview of the task.

Requestor Information: Details about the individual requesting the work.

Task Details: Specific instructions and expectations for the work.

Priority Level: Indicates the urgency of the task.

Assignment Information: Identifies the individual or team responsible for the task.

There are various types of work orders tailored to specific needs. Maintenance work orders focus on routine upkeep, while service work orders address customer requests. Repair work orders are critical for fixing issues, and construction work orders detail project specifications. Each type requires a unique approach in terms of information and tracking methods, underlining the importance of understanding the work order's purpose.

Maintenance Work Orders: For regular upkeep of equipment or facilities.

Service Work Orders: To handle specific customer requests or tasks.

Repair Work Orders: Addressing immediate fixes needed in systems or processes.

Construction Work Orders: Detailing tasks related to building and infrastructure projects.

Creating a work order process checklist

An effective work order process checklist is instrumental in ensuring that tasks are managed efficiently from start to finish. The first step involves identifying the specific tasks and associated responsibilities, ensuring everyone knows their roles. Next, it’s crucial to organize the workflow steps logically. This organization may involve outlining the sequence of tasks, designating responsible individuals, and ensuring timelines are appropriately established. Establishing clear submission guidelines helps prevent confusion and accelerates the overall process.

Identify Tasks and Responsibilities: Clarifies what needs to be done and who will do it.

Organize Workflow Steps: Structuring the process for maximum efficiency.

Establish Submission Guidelines: Offering clear instructions on how to submit work orders.

Essential items to include in your checklist should cover problem identification, ensuring the core issue is highlighted for resolution, followed by an assignment protocol that clearly delineates who is responsible for addressing the task. Setting deadlines is equally important, as this fosters accountability and promotes timely completion of tasks.

Problem Identification: Isolating the core issue to be resolved.

Assignment Protocol: Defining who takes charge of completing each task.

Deadline Setting: Establishing timeframes to enhance accountability.

A sample work order process checklist can be a valuable resource. This checklist can serve as a general guide, incorporating all necessary elements that a user should complete when generating a work order, streamlining the overall process and enhancing efficiency.

Utilizing the work order checklist

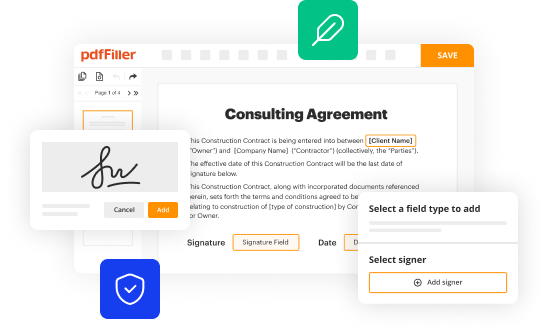

In a digital age, utilizing an interactive checklist can significantly enhance work order management. Implementing dynamic features, such as assigning tasks directly from the checklist, enables teams to communicate more effectively. Utilizing tools like pdfFiller allows users to edit PDFs seamlessly, eSign documents directly within the platform, and collaborate with teams in real-time. Such features save time and ensure that everyone stays on the same page throughout the work order process.

Editing PDFs Seamlessly: Updating work orders as needed without hassle.

eSigning Documents Directly: Ensuring compliance and formal agreement on tasks.

Collaborating with Teams in Real-Time: Fostering communication and transparency.

Common mistakes to avoid when creating work orders include leaving out critical information, which can cause delays and confusion. Additionally, failing to communicate assignments clearly can lead to misunderstandings and poor task execution. By ensuring all necessary details are included and roles are explicitly stated, teams can prevent these frequent pitfalls.

Leaving Out Critical Information: Omitting details can lead to task failures.

Failing to Communicate Assignments Clearly: Miscommunication hampers efficiency.

Advanced work order process strategies

To streamline work order processes, leveraging technology plays a pivotal role. Utilizing software designed for work order management can significantly reduce workload and enhance tracking capabilities. Mobile solutions are particularly advantageous, allowing users to manage work orders from anywhere, increasing flexibility and responsiveness. This technological integration not only improves workflow efficiency but also enhances overall team collaboration.

Benefits of Using Software for Work Order Management: Automation reduces errors and saves time.

Mobile Solutions for On-the-Go Work Order Tracking: Boosts responsiveness to immediate needs.

Analyzing work order data is vital for continual process improvement. By monitoring key metrics, such as completion times and error rates, organizations can identify inefficiencies and areas for enhancement. Surveying user feedback can also provide invaluable insights that inform future work order processes, benefiting both the organization and its clients.

Key Metrics to Monitor: Tracking efficiency and effectiveness of work order execution.

Utilizing Feedback for Enhanced Efficiency: Leveraging insights to refine processes.

Work order formats and templates

There are numerous formats available for work orders, catering to varying needs and preferences. Printable templates serve as convenient options for organizations that prefer physical documentation. On the other hand, online forms allow for effortless data entry and retrieval, streamlining the process even further. Customizable work order formats enable teams to tailor their documents to fit specific operational needs, ensuring maximum relevance and efficiency.

Printable Templates vs. Online Forms: Choosing the best format for your workflow.

Customizable Work Order Formats: Enhancing operational efficiency through personalization.

Industry-specific work order templates also offer tailored solutions that can enhance functionality. For instance, HVAC work order templates focus on specific maintenance tasks related to heating and cooling systems, while painting work order templates streamline processes for contractors in the paint industry. Additionally, IT work order templates cater specifically to tech-related services, highlighting the need for specialized formats that resonate with specific industries.

HVAC Work Order Template: Streamlining specific tasks in heating and cooling.

Painting Work Order Template: Tailoring processes for painting contractors.

IT Work Order Template: Customizing for technical support and services.

Custom Templates for Unique Needs: Catering to specialized industry requirements.

Best practices for managing work orders

Facilitating effective communication is critical for the success of work order management. Keeping stakeholders informed about project statuses, deadlines, and potential delays fosters trust and reduces anxiety around pending tasks. Regular status updates provide transparency, allowing teams to make necessary adjustments proactively. Implementing feedback loops encourages team engagement, as it empowers members to contribute suggestions that streamline workflows.

Keeping Stakeholders Informed: Regular updates build trust and enhance teamwork.

Regular Status Updates: Providing transparency to mitigate confusion.

Encouraging team engagement in work order submissions is another essential best practice. By fostering a culture where team members feel comfortable submitting work orders, organizations can reduce backlog and enhance service delivery. Implementing feedback loops further refines processes, as it allows individuals to share insights based on their firsthand experiences with the system.

Encouraging Team Engagement: Fostering a supportive environment for submissions.

Implementing Feedback Loops: Refining processes through team input.

Troubleshooting common work order issues

Identifying and addressing delays in work order processing requires a keen understanding of the workflow and potential bottlenecks. Analyzing the root causes of holdups enables teams to implement corrective measures, ensuring a smoother process moving forward. Additionally, managing discrepancies and errors in submitted work orders is vital; a clear review protocol can help catch mistakes early, preventing further complications.

Identifying Delays: Analyzing workflows to locate bottlenecks.

Managing Discrepancies: Creating a review protocol to catch errors.

Strategies for resolving conflicts over assignments are also necessary; fostering a collaborative environment where team members feel comfortable addressing issues directly can mitigate tension and enhance overall cooperation. Implementing conflict-resolution training can further equip teams with the skills needed to resolve disputes efficiently.

Fostering a Collaborative Environment: Encouraging open communication among team members.

Implementing Conflict-Resolution Training: Equipping team members with necessary skills.

Future trends in work order management

The future of work order management is poised for transformation with automation playing a significant role. Automation streamlines repetitive tasks, minimizes human error, and allows teams to focus on strategic initiatives. Implementing artificial intelligence in work order processes further enhances this trend, helping organizations predict maintenance needs and optimize workloads more effectively.

How Automation is Shaping the Future: Reducing manual errors and increasing efficiency.

The Role of AI in Work Order Processes: Enhancing predictive capabilities for maintenance.

Enabling Remote Work Order Management Solutions: Facilitating operational flexibility.

Conclusion

Having a streamlined work order process is not just beneficial—it’s imperative for enhancing operational efficiency. Emphasizing clarity and organization within the work order process checklist empowers teams to manage tasks effectively and to drive productivity. By leveraging tools like pdfFiller, users can seamlessly edit PDFs, eSign, and collaborate on their work order processes, transforming how tasks are assigned and completed across organizations.