Get the free Technical Operation and Maintenance Requirements Manual for Rural Piped System

Get, Create, Make and Sign technical operation and maintenance

How to edit technical operation and maintenance online

Uncompromising security for your PDF editing and eSignature needs

How to fill out technical operation and maintenance

How to fill out technical operation and maintenance

Who needs technical operation and maintenance?

A comprehensive guide to technical operation and maintenance forms

Understanding technical operation and maintenance forms

A technical operation and maintenance form is a crucial document used in various industries, including manufacturing, construction, and facilities management. This form serves as a detailed record that encompasses the essential information regarding the operational status and maintenance history of equipment or systems. Proper documentation helps teams track performance, ensure regulatory compliance, and streamline maintenance processes.

Effective documentation is vital in operations and maintenance. It not only aids in maintaining an organized approach but also facilitates communication between teams, minimizes downtime, and provides a historical reference. Inadequate documentation can lead to costly errors or misunderstandings, making it essential to utilize a comprehensive technical operation and maintenance form.

Key components of a technical operation and maintenance form typically include: details of the equipment, maintenance schedules, inspection records, issue descriptions, and action items. These elements ensure that all personnel involved have access to vital data necessary for informed decision-making.

Benefits of using pdfFiller for technical operations and maintenance

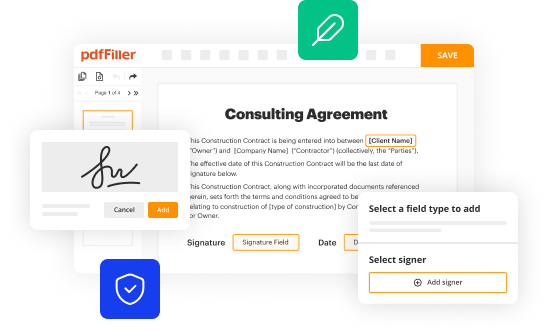

pdfFiller serves as an invaluable tool for managing technical operation and maintenance forms, providing various benefits that enhance the document management process. One of the significant advantages is streamlined document management. Users can easily create, edit, and store their forms in one centralized platform, reducing the time spent searching for documents across multiple systems.

Another key benefit is enhanced collaboration features. With pdfFiller, teams can work together on forms in real-time, making it easier to gather input and finalize documents. The platform also allows for easy sharing, ensuring that all relevant stakeholders have access to the latest information. Accessibility from anywhere is another advantage, as the cloud-based solution enables personnel to view and edit documents from any location, which is particularly crucial in field operations.

Additionally, pdfFiller offers legal compliance and eSigning capabilities. This functionality ensures that the forms meet legal requirements, streamlining processes while safeguarding data integrity. Overall, utilizing pdfFiller results in more efficient operations and enhanced team collaboration in managing technical operation and maintenance forms.

Preparing to fill out the technical operation and maintenance form

Filling out a technical operation and maintenance form requires careful preparation to ensure accuracy and completeness. Start by identifying essential information to include, which may consist of contact details, equipment specifications, operational procedures, and maintenance schedules. Having this information readily available will facilitate the process and reduce the chance of errors.

Assembling your team is also a critical step. Clearly define roles and responsibilities, such as who will fill out specific sections of the form and who is responsible for reviewing it. For instance, the operations manager may oversee the overall completion, while maintenance staff input technical details.

Gathering necessary resources and data is just as vital. Collect historical maintenance records, technical manuals, and relevant guidelines to aid in filling out the form accurately. Well-prepared teams are more likely to efficiently complete forms that meet operational needs.

Step-by-step instructions for completing the technical operation and maintenance form

To begin, access the form on pdfFiller. The user-friendly interface allows for quick navigation to existing templates and forms. If you are starting from scratch, pdfFiller also provides customizable templates tailored to common operational needs.

Next, customize the form for your needs, incorporating any specific operational requirements or industry practices. When filling out the form, adopt a detailed approach: ensure all sections are complete, accurate, and up to date. Use precise technical data and avoid vague descriptions to enhance clarity.

After completing the form, reviewing and editing your submission is crucial. Take time to proofread for any spelling or data entry errors. Consider revising any sections that seem ambiguous or lack sufficient detail. A comprehensive review helps prevent future misunderstandings and improves the quality of your documentation.

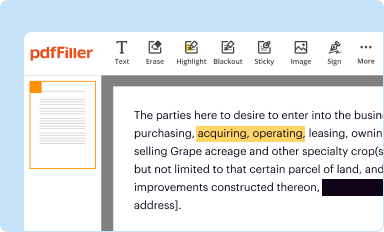

Leveraging interactive tools on pdfFiller

pdfFiller's interactive features significantly enhance the usability of technical operation and maintenance forms. Utilizing these features can streamline workflows and make the document management process more efficient. For example, interactive fields allow for easy data entry without formatting errors, while checkboxes and dropdown lists guide users in providing standardized responses.

Collaboration tools on pdfFiller are essential for gathering team feedback and input. Team members can add comments, suggestions, or corrections directly within the document, promoting real-time collaboration. Moreover, version control features enable users to track changes over time, ensuring that everyone is working from the latest version of the form.

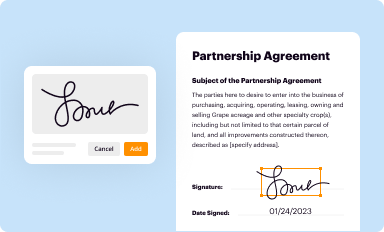

Signing and managing your technical operation and maintenance form

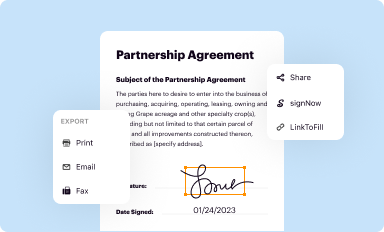

E-signatures provide a secure and efficient way to sign off on technical operation and maintenance forms. With pdfFiller, the process for eSigning is straightforward: users can sign the document electronically, ensuring that approvals are documented without the need for physical signatures. This feature is particularly beneficial in remote work scenarios where team members may not be in the same location.

Once the form has been completed and signed, sharing and distributing it within the organization is critical. pdfFiller offers multiple methods for sharing documents, including secure links or email distributions. Best practices for document storage and retrieval involve utilizing a structured file management system. This promotes long-term management of forms, minimizing the risk of lost or outdated documents.

Real-life examples of technical operation and maintenance forms

Different industries employ technical operation and maintenance forms tailored to their specific needs. For instance, in manufacturing, forms could track machinery status and maintenance schedules to maximize uptime and efficiency. In construction, these forms might detail equipment inspections and safety checks, while in facility management, regular maintenance logs might be used to oversee HVAC systems and plumbing.

Case studies of effective usage demonstrate how various organizations leverage these forms to enhance operational efficiency. Businesses that rigorously maintain documentation typically report improved equipment reliability, streamlined maintenance processes, and increased staff accountability.

Ongoing management and updates for technical operation and maintenance forms

Establishing a review cycle for your technical operation and maintenance forms is necessary to ensure they remain relevant and effective. Regular reviews allow teams to identify areas for improvement, ensuring that information is up to date and reflective of operational realities.

Monitoring and evaluating performance is also essential. Using feedback loops helps teams understand the effectiveness of their forms and the data captured within them. Adaptations may be required in response to changes in operations or equipment, ensuring that documentation evolves alongside organizational needs.

Frequently asked questions about technical operation and maintenance forms

Common challenges associated with completing technical operation and maintenance forms include lack of clarity and incomplete data entries. To address these issues, ensure all team members are adequately trained on form requirements and the information necessary for completion. Optimization can also be achieved through regular team reviews of completed forms, identifying areas to enhance efficiency.

It is beneficial to encourage questions and proactive communication among team members about any uncertainties regarding form completion. Continuous improvement efforts contribute to maintaining effective technical operation and maintenance documentation.

Additional considerations for effective operations and maintenance management

Integrating technical operation and maintenance forms into larger maintenance strategies can provide a more comprehensive view of organizational performance. For example, linking these forms with inventory management systems can offer insights into equipment lifecycle management and resource allocation.

Collaborating with external stakeholders, such as equipment suppliers and service providers, can enhance the value of the information captured within these forms. Establishing partnerships for shared access to maintenance data and practices fosters better operational synergy.

Training and onboarding new users on pdfFiller is crucial to maximizing the platform's benefits. Regular training sessions can ensure that all personnel understand how to effectively utilize the tool for managing technical operation and maintenance forms, leading to improved efficiency across the board.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify technical operation and maintenance without leaving Google Drive?

Where do I find technical operation and maintenance?

How do I fill out technical operation and maintenance on an Android device?

What is technical operation and maintenance?

Who is required to file technical operation and maintenance?

How to fill out technical operation and maintenance?

What is the purpose of technical operation and maintenance?

What information must be reported on technical operation and maintenance?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.