Get the free Technical Conditions „flat Glass and Mirror Processing“

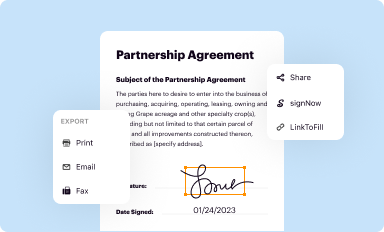

Get, Create, Make and Sign technical conditions flat glass

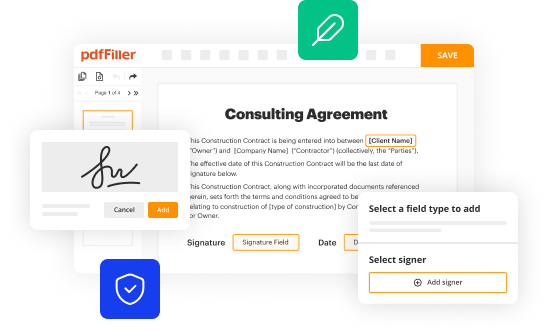

How to edit technical conditions flat glass online

Uncompromising security for your PDF editing and eSignature needs

How to fill out technical conditions flat glass

How to fill out technical conditions flat glass

Who needs technical conditions flat glass?

Technical Conditions Flat Glass Form: A Comprehensive Guide

Understanding flat glass: Core technical conditions

Flat glass, a crucial material used widely in architecture and manufacturing, refers to glass that is produced in uniform thicknesses and flat surfaces. This versatile material is utilized in windows, mirrors, and even furniture, serving both functional and aesthetic purposes across various sectors. Its applications range from everyday household items to large-scale architectural installations, demonstrating its significance in modern design and construction.

To truly appreciate flat glass, it's essential to understand its key technical properties. These include thickness and flatness specifications, optical clarity and light transmission, as well as thermal performance and insulation properties. Each specification influences the effectiveness and suitability of the glass for particular uses, thereby determining its overall value in the marketplace.

Essential technical conditions for flat glass manufacturing

The manufacturing of flat glass involves specific processes that ensure the final product meets rigorous standards. The primary raw materials include silica sand, soda ash, and limestone. These materials are carefully mixed and melted at high temperatures to produce a molten glass, which is then shaped and cooled into thin sheets.

The float glass process, the most widely used method, involves floating molten glass on molten tin to create a perfectly flat surface. There are also alternative production methods such as the sheet and cast glass processes, though they are less common. Quality control is paramount throughout manufacturing, with multiple checks in place to assess clarity, thickness uniformity, and other critical specifications.

Assessing technical specifications based on usage

Technical conditions for flat glass vary greatly depending on its application. In residential settings, enhancing energy efficiency is critical. This includes understanding heat gain and loss through windows and using materials that meet specific insulation standards. Noise reduction is another factor; in urban areas, thicker or laminated glass can significantly diminish sound transmission, providing a more comfortable living environment.

On the other hand, commercial applications have their own stringent requirements. Safety standards dictate the use of tempered or laminated glass in many buildings to prevent injury from shattering. Aesthetic considerations, including color and finishing options, are also important for architects and designers. These features enhance the building's overall appeal while complying with the safety regulations.

Customizing flat glass: Options and modifications

Customization is a significant advantage of flat glass, allowing it to meet specific project needs. Edge treatments can enhance both safety and aesthetics. Common options include polished edges or various bevels, which can improve the visual appeal of glass in furniture and fixtures.

Moreover, the ability to create cutouts, holes, and custom shapes adds flexibility for designers. Techniques like waterjet cutting enable precision without compromising the integrity of the glass. Various coatings and treatments are also available to enhance properties such as scratch resistance, UV filtering, and thermal insulation, making flat glass suitable for a wider range of applications.

Sustainability in flat glass production

Sustainability is no longer an optional consideration in the flat glass industry; it is imperative. The ecological footprint of manufacturing flat glass involves energy consumption and emissions, prompting many producers to adopt greener technologies. This includes methods that reduce waste and improve energy efficiency, as well as sourcing recycled materials whenever possible.

Recyclability is another vital aspect of flat glass. Post-consumer recycled glass can be reintroduced into the production process, closing the loop and minimizing the demand for virgin materials. Material recovery facilities are equipped to handle end-of-life glass products, making it easier for consumers to recycle.

Advanced technical conditions: Performance parameters

Flat glass must endure numerous performance parameters to ensure it meets relevant standards for safety and durability. Temperature resistance tests are crucial, as thermal shock ratings gauge how well the glass can withstand sudden temperature changes. This is especially important in regions with drastic weather fluctuations, where the integrity of glass can be compromised if not manufactured correctly.

Durability testing is another critical component of quality assessment. Standards for impact resistance require that glass be able to withstand certain stresses without breaking. Increased emphasis on safety in both residential and commercial environments has led to more rigorous testing protocols, ensuring that the end product is robust and reliable.

Interactive tools and resources for users

To help users navigate through the specifications and potential configurations of flat glass, several interactive tools are available. Document templates specific to flat glass specifications can provide a foundation for drafting project plans or detailed specifications quickly and efficiently.

Additionally, interactive calculators enable users to determine optimal sizes, weights, and costs of glass sheets tailored to their needs. Step-by-step guides can assist in selecting the right glass based on technical conditions, ensuring that every project aligns with both functional requirements and aesthetic goals.

Frequently asked questions about flat glass technologies

Addressing common misconceptions about flat glass is essential for a well-informed customer base. Many believe that all glass is the same, while in fact, glass varieties differ vastly based on their manufacturing and treatment options. Understanding these differences allows consumers to make better choices for their specific needs.

Issues can also arise in the application of flat glass technologies. Common troubleshooting concerns include fogging, improper installation, and miscalculations in thickness. By providing guidance on resolving these technical issues, manufacturers and suppliers can ensure that users maintain optimal performance from their flat glass products.

Real-world applications of flat glass in design and architecture

In design and architecture, flat glass is increasingly being used in innovative ways. It is being featured prominently in skyscrapers, where glass facades create stunning, modern aesthetics while allowing natural light to fill the interiors. Case studies showcase various unique applications, such as curved glass structures that offer both form and functionality.

Current design trends reveal a preference for large, expansive glass installations that can transform spaces. Architects are exploring various textures, colors, and treatments, leading to a renaissance in how flat glass is perceived and utilized. The growing emphasis on sustainability has also sparked interest in recycled glass, which adds an eco-friendly dimension to modern design.

Connecting with experts

Engaging with professionals in the flat glass industry can provide valuable insights and personalized advice. Many manufacturers offer consulting services and can guide clients through material selection, project specifications, and installation processes. Building relationships with experts can facilitate the best outcomes for your specific flat glass needs.

Moreover, staying updated on new technologies and trends in flat glass is essential for those involved in this sector. Signing up for newsletters or following industry-specific publications can keep individuals and teams informed of the latest innovations, helping them to remain competitive and knowledgeable in their endeavors.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I complete technical conditions flat glass online?

How do I fill out the technical conditions flat glass form on my smartphone?

How do I edit technical conditions flat glass on an Android device?

What is technical conditions flat glass?

Who is required to file technical conditions flat glass?

How to fill out technical conditions flat glass?

What is the purpose of technical conditions flat glass?

What information must be reported on technical conditions flat glass?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.