Get the free Safety, Operation & Preventive Maintenance Manual

Get, Create, Make and Sign safety operation preventive maintenance

How to edit safety operation preventive maintenance online

Uncompromising security for your PDF editing and eSignature needs

How to fill out safety operation preventive maintenance

How to fill out safety operation preventive maintenance

Who needs safety operation preventive maintenance?

The Essential Guide to Safety Operation Preventive Maintenance Forms

Understanding safety operation preventive maintenance forms

A safety operation preventive maintenance form is a structured document that allows organizations to perform routine checks and maintenance on equipment, ensuring they operate safely and efficiently. This form is crucial in industries such as manufacturing, construction, and transportation, where equipment failure can lead to accidents, injuries, or fatal incidents.

The importance of these forms cannot be overstated. They serve as a formalized method to track maintenance activities and safety protocols, helping organizations avoid costly downtime and maintain compliance with safety regulations. Regular use of these forms supports accident prevention and enhances overall workplace safety.

How to create a safety operation preventive maintenance form

Creating an effective safety operation preventive maintenance form requires careful consideration of the information it should capture. Essential elements include equipment identification, the schedule of inspections, maintenance procedures, and safety checklists that ensure comprehensive assessments.

When constructing your form, begin by outlining the essential information. Clearly label sections for equipment identification, detailing specifications like model numbers, serial numbers, and descriptions. Incorporate a schedule section that sets out when different maintenance checks should occur, assisting teams in sticking to timely inspections.

To structure your form effectively, consider layout and clarity. Use checkboxes for routine checks and blank fields for detailed notes. This not only simplifies data collection but makes the form less intimidating and more user-friendly.

Digital vs. traditional forms: which is right for you?

In today's fast-paced environment, choosing between digital and traditional paper forms can significantly impact efficiency. Digital safety operation preventive maintenance forms offer several advantages, including easy accessibility, faster completion, and real-time data management.

For teams operating across multiple locations, cloud-based solutions allow for seamless access to forms, enabling field workers to input data on-the-go. In contrast, paper-based processes can hinder productivity, resulting in delays in reporting and evaluation.

Filling out the safety operation preventive maintenance form

Filling out a safety operation preventive maintenance form should be a systematic process. Begin by gathering all necessary data such as equipment details and previous maintenance records before starting the fill-out process. This preparedness forms the foundation for accurate and comprehensive reporting.

Each section of the form requires specific attention. Start with equipment identification, including essential details like operational status and repair history. Next, clearly document scheduled inspections, and ensure maintenance procedures follow checklists that promote safe practices. Remember, clarity is vital; vague entries can lead to miscommunications.

Avoid common mistakes such as incomplete sections or subjective evaluations. Ensure every entry is clearly typed or written to avoid misinterpretation later.

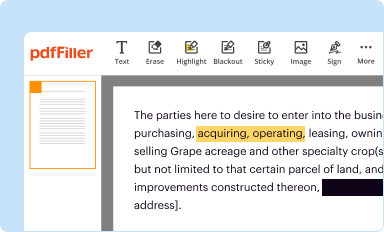

Editing and collaborating on your maintenance form

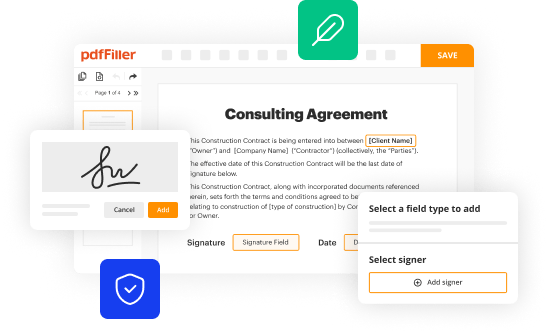

Collaboration is a critical aspect of maintaining safety operation preventive maintenance forms. Utilizing tools like pdfFiller facilitates efficient document editing and ensures that all team members can contribute without confusion. The platform allows users to modify forms in real-time, enhancing teamwork.

Sharing forms safely among team members can further enhance collaboration. Clear arrangements regarding which individual can make specific changes minimizes errors and maintains accuracy. Use collaborative edit features judiciously to ensure compliance and accurate documentation.

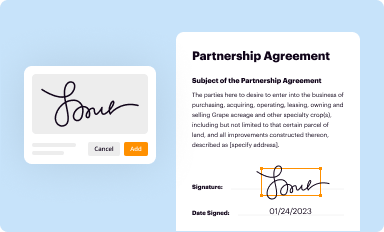

Signing and finalizing your safety operation preventive maintenance form

Finalizing the safety operation preventive maintenance form requires a signature process that signifies responsibility and accountability. Employing electronic signature (eSigning) tools streamlines the approval process, eliminating the delays associated with traditional pen-and-paper methods.

Ensuring that your form is signed not only grants you quick approval but also fortifies your compliance with safety regulations. A digital signature holds the same legal standing as a handwritten one, thereby speeding up processes significantly.

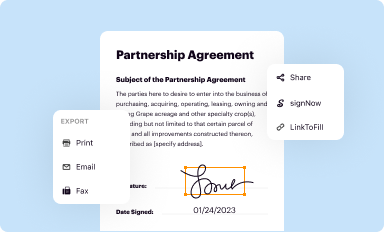

Managing and storing your completed maintenance forms

Effective management and storage of completed safety operation preventive maintenance forms is essential for both future reference and compliance audits. Adopt best practices such as digitizing forms for secure cloud storage, ensuring they are easily retrievable when needed.

pdfFiller offers a secure platform to store documents, making it easy to manage completed forms and access them anytime. Organizational techniques, such as categorizing by date or equipment type, can significantly enhance efficiency, particularly during audits or operational reviews.

Integrating safety operations maintenance into business practices

Regular preventive maintenance through safety operation forms is integral to effective business practices. Organizations that prioritize these maintenance protocols often see benefits such as decreased equipment downtime and improved safety records. This proactive approach not only aligns with industry standards but also fosters a culture of safety within the workforce.

To illustrate the impact of these practices, consider case studies where companies implemented strict preventive maintenance checks and experienced significant reductions in incidents and increases in operational efficiency. Aligning maintenance approaches with industry best practices not only ensures safety compliance but also enhances overall business performance.

Interactive tools for enhanced preventive maintenance

Interactive tools such as those offered by pdfFiller facilitate a more engaging maintenance process. These tools include features for automated reminders, scheduling, and notifications that help ensure critical maintenance tasks are never overlooked.

Using these interactive tools can dramatically improve a team's ability to manage maintenance schedules, ensuring that all members are on the same page regarding inspections and upkeep tasks. By implementing these digital solutions, organizations can achieve higher compliance rates while significantly enhancing maintenance productivity.

Tracking and reporting maintenance effectiveness

Tracking the effectiveness of maintenance efforts relies on capturing accurate metrics. Organizations should focus on various metrics such as downtime frequency, repair costs, and completion rates of scheduled maintenance tasks. Collecting data from your safety operation preventive maintenance forms plays a pivotal role in informed decision-making.

Utilizing analytical features provided by platforms like pdfFiller can assist in generating reports that visualize maintenance performance over time. This data is invaluable in identifying areas for improvement and optimizing operational strategies. Regular evaluation fosters a culture of continuous improvement, promoting not only equipment safety but also overall workplace efficiency.

Frequently asked questions (FAQ) on safety operation preventive maintenance forms

A common query relates to how a safety operation preventive maintenance form differs from traditional maintenance documentation. The specificity and focus on safety compliance set it apart, making it essential for industries that prioritize operational safety.

Additionally, users often wonder about the legal implications associated with these forms. Filling them out accurately is crucial as they can impact regulatory compliance. It’s advisable for users to familiarize themselves with any industry-specific requirements that may enhance their adherence to organizational standards.

Success stories and testimonials

Numerous organizations have transformed their safety operation practices through the use of preventive maintenance forms. Companies that have adopted structured maintenance protocols often share profound improvements in both safety records and operational efficiency.

User experiences with pdfFiller for preventive maintenance documentation underscore its role in simplifying the documentation process while enhancing compliance. Customer testimonials reveal that improved documentation practices can lead to fewer workplace incidents and a more engaged workforce.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify safety operation preventive maintenance without leaving Google Drive?

How do I fill out the safety operation preventive maintenance form on my smartphone?

How do I complete safety operation preventive maintenance on an iOS device?

What is safety operation preventive maintenance?

Who is required to file safety operation preventive maintenance?

How to fill out safety operation preventive maintenance?

What is the purpose of safety operation preventive maintenance?

What information must be reported on safety operation preventive maintenance?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.