Get the free Fastener Calculation Form

Get, Create, Make and Sign fastener calculation form

How to edit fastener calculation form online

Uncompromising security for your PDF editing and eSignature needs

How to fill out fastener calculation form

How to fill out fastener calculation form

Who needs fastener calculation form?

Fastener Calculation Form: A Comprehensive How-to Guide

Understanding fastener calculations

Fastener calculations are crucial in engineering, as they ensure that structures can withstand specified loads without failure. Each application, whether in construction, automotive design, or aerospace, relies on precise calculations of fasteners to maintain integrity. Proper fastener selection based on calculations helps prevent catastrophic failures in environments where safety is paramount.

Fasteners, such as bolts and screws, play a significant role across various industries, from holding together aircraft components to securing furniture. Understanding key terms like torque, tension, yield strength, and tensile strength is essential in making informed decisions during the fastening process.

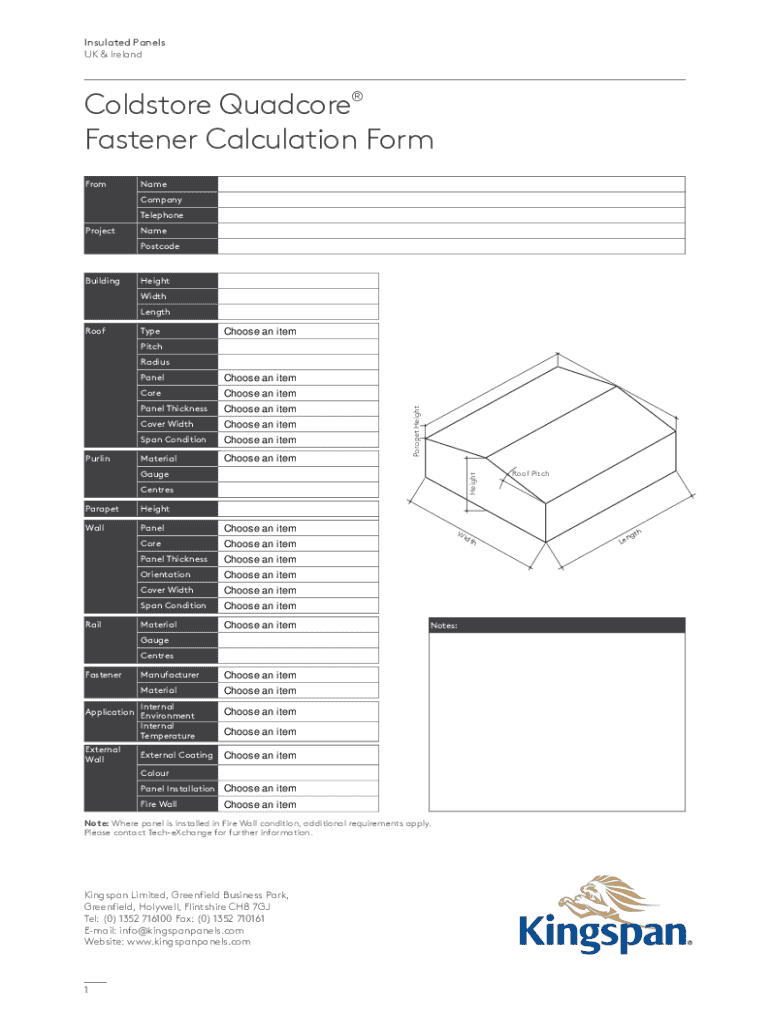

The fastener calculation form: essential components

The fastener calculation form is a structured document designed to collect necessary data for calculating the specifications of fasteners. Without the proper inputs, results may lead to inefficient or even risky fastening solutions. Each section of the form is tailored to gather the critical information needed for accurate calculations.

Key fields in the fastener calculation form include the selection of fastener type, load specifications, material properties, and environmental factors. Proper input of each field ensures the reliability of the calculations provided by the form and subsequently enhances the overall quality of the fastening process.

Step-by-step guide to completing the fastener calculation form

Completing the fastener calculation form requires a systematic approach to ensure accuracy. Follow these steps for a comprehensive understanding.

Step 1: Selecting the fastener type

Different applications will require different fastener types. For example, heavy machinery may need high-strength bolts, while lighter applications might do well with screws or rivets. Evaluating the applications and load requirements will guide you in selecting the most suitable type.

Step 2: Specifying load requirements

Understanding the types of loads your fastener will endure is crucial. Static loads are constant, dynamic loads vary, and impact loads occur suddenly. For instance, in automotive design, screws in suspension systems must withstand both static and dynamic loads, requiring careful calculations.

Step 3: Inputting material properties

The material of the fastener affects its strength and performance under load. Common materials include steel, aluminum, and titanium, each with unique properties. Ensure accurate input by referring to material property charts during this step.

Step 4: Entering environmental conditions

Environmental factors can significantly impact fastener performance. For instance, high humidity may lead to corrosion in certain metal fasteners. Therefore, it's essential to consider these conditions while completing calculations to avoid future failures.

Utilizing interactive tools for fastener calculations

Online fastener calculation tools have revolutionized the way engineers and designers compute their fastener requirements. These interactive features provide real-time calculations and can instantly notify users of any input errors, enhancing both accuracy and efficiency.

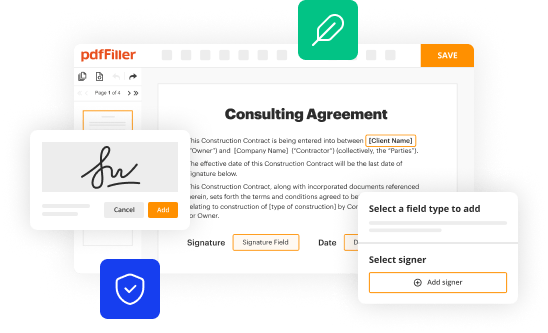

With online platforms like pdfFiller, users can access tools that simplify the completion of fastener calculation forms. These tools are designed to guide users through the necessary inputs and provide instant calculations based on entered data.

Common fastener calculation formulas

Understanding the basic formulas related to fasteners is essential for accurate calculations. The torque calculation formula, for example, ties together torque and tension, illustrating their relationship in fastening applications.

Another significant calculation involves yield strength and tensile strength, which directly inform how much load a fastener can handle before failure. To illustrate, if a bolt is rated at a given yield strength, it is imperative to ensure that the application does not exceed that limit through thorough calculations.

Best practices for fastening techniques

Proper fastening techniques ensure the longevity and safety of assembled structures. Applying the correct torque consistently minimizes common issues associated with fasteners. It is vital to follow the manufacturer's specifications to achieve optimal tightness, thus preventing loosening or breakage during operation.

Avoiding common mistakes during the fastening process is equally critical. Over-torquing or under-torquing can lead to fastener failure, resulting in safety hazards. Regular training and adherence to guidelines can improve the overall quality of fastening techniques among various teams.

Troubleshooting fastener issues

Fasteners can face various issues during their lifespan, notably over-torquing or under-torquing, which can compromise structural integrity. Recognizing the symptoms of these problems is vital for maintenance and troubleshooting.

Additionally, conditions such as corrosion or fatigue failures can lead to catastrophic outcomes if not addressed. Techniques to solve these problems often involve readjustment of torque settings or a full re-evaluation of previously made calculations and inputs. Maintaining detailed records can assist in troubleshooting efforts.

Advanced calculations and considerations

When considering fastener performance, multiple external factors must be evaluated. Load duration factors, temperature factors, and the presence of corrosive elements can all influence a fastener's effectiveness. Understanding these factors can enhance the design process, promoting longer-lasting and safer structures.

Engineers must also integrate fastener calculations into structural designs to ensure appropriate strength and durability. This necessitates comprehension of quality standards and testing procedures relevant to the materials used, ensuring that designs meet industry regulations.

Engaging with expert advice

For individuals and teams grappling with complex fastening projects, accessing educational content can significantly enhance their understanding. Integrating resources such as webinars, detailed articles, and tutorials available on platforms like pdfFiller can provide foundational knowledge.

Additionally, consultation options with fastening experts can guide users through intricate calculations and considerations, providing a collaborative and educational experience that solidifies learning.

Real-world applications of fastener calculations

Fastener calculations play a pivotal role across multiple sectors. Case studies featuring successful applications demonstrate the significant impact of precise calculations on the aerospace, automotive, construction, and manufacturing industries. Each sector benefits from employing accurate fastener calculations to ensure safety and longevity in their structures.

In aerospace, for instance, calculations dictate the performance of critical components under extreme conditions, while in manufacturing, precise specifications enhance product reliability. As the industry evolves, emerging trends in fastener technology will continue to reshape how calculations are approached, driving innovation and efficiency.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an eSignature for the fastener calculation form in Gmail?

How do I fill out fastener calculation form using my mobile device?

Can I edit fastener calculation form on an Android device?

What is fastener calculation form?

Who is required to file fastener calculation form?

How to fill out fastener calculation form?

What is the purpose of fastener calculation form?

What information must be reported on fastener calculation form?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.