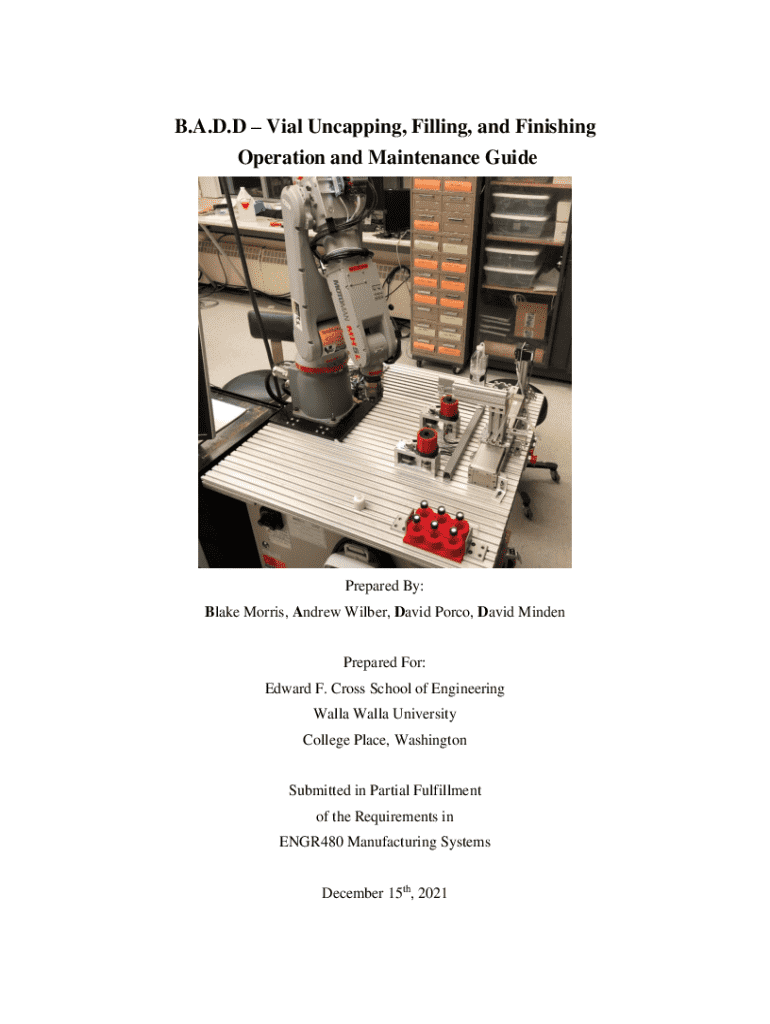

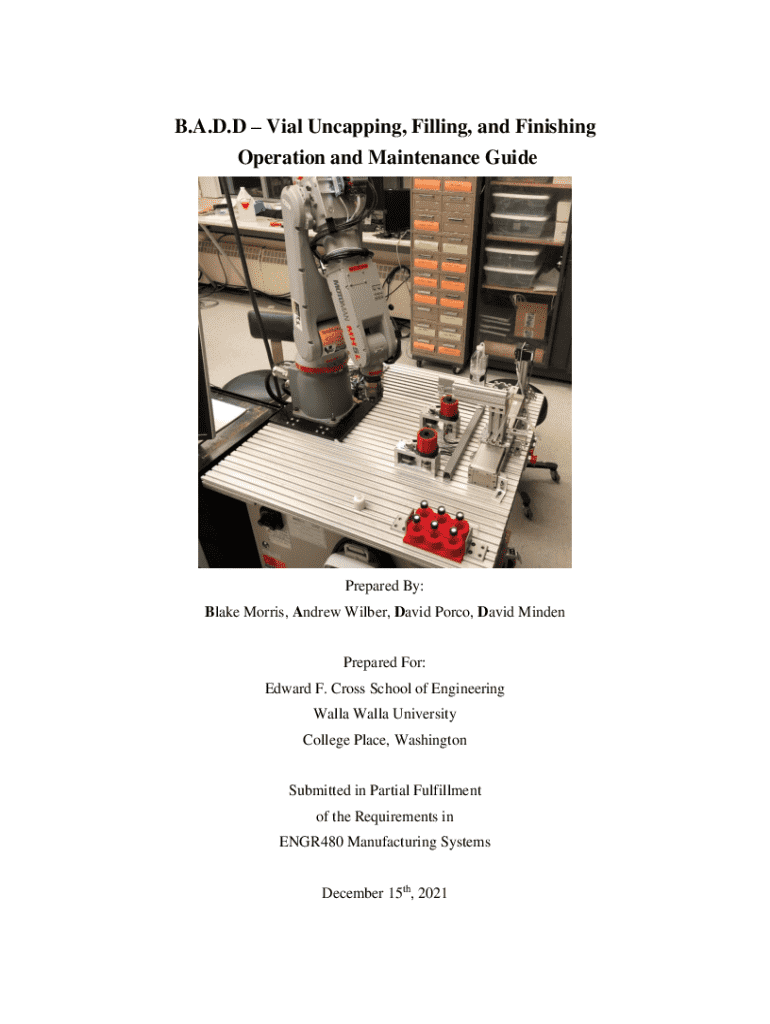

Get the free B.a.d.d – Vial Uncapping, Filling, and Finishing Operation and Maintenance Guide - p...

Get, Create, Make and Sign badd vial uncapping filling

How to edit badd vial uncapping filling online

Uncompromising security for your PDF editing and eSignature needs

How to fill out badd vial uncapping filling

How to fill out badd vial uncapping filling

Who needs badd vial uncapping filling?

A comprehensive guide to badd vial uncapping and filling form

Understanding the badd vial filling process

A badd vial is a specialty container designed for the storage and transfer of solutions in various industries, particularly in pharmaceuticals and laboratory settings. Understanding the badd vial's structure and design is crucial for effective use. These vials often need to be filled and uncapped under stringent conditions to prevent contamination and ensure the integrity of the solution inside.

Superb handling of badd vials is paramount. Improper techniques can lead to contamination—or worse, compromised results in experiments or patient treatments. Thus, a clear understanding of the uncapping and filling process significantly enhances accuracy and safety.

Preparation for uncapping the badd vial

Before initiating the uncapping process, it’s vital to gather all essential tools and materials. Common items include gloves, syringes, alcohol wipes, and, if necessary, specialized vial openers. All tools should be sterile to minimize any risk of contamination, which could lead to significant errors in laboratory results or patient safety risks.

Creating a clean workspace is equally important. Ensure that surfaces are disinfected, clutter is minimized, and materials needed for the uncapping and filling process are organized. Efficiency is enhanced when everything is within easy reach before starting the process.

The uncapping process

Uncapping a badd vial correctly requires a methodical approach to ensure both safety and accuracy. Start by inspecting the vial for any visible damage or defects that may affect its usability. If any such damage is detected, do not attempt to uncap or use the vial.

Next, wear gloves and other protective gear as necessary to guard against spills and contamination. To remove the cap safely, grip the vial firmly and twist off the cap, ensuring that you do so carefully to avoid spills and exposure to the contents. If the cap is particularly tight, using a rubber grip or cloth can help without introducing contaminants.

Common challenges during this step include stuck caps that are resistant to removal. In these cases, gently twisting the cap while positioning the vial snugly on a stable surface can help. Always remember to check the integrity of the vial afterward to ensure it's still suitable for use.

Filling the badd vial

Once the vial is uncapped, the next step is preparing the filling solution. Depending on the application, various filling solutions may be used, and it’s important to follow standard operating procedures for the specific solution type chosen. Once the filling solution is prepared, ensure proper storage conditions to maintain its effectiveness.

When filling the badd vial, selecting the right syringe is crucial. A syringe with a suitable volume and tip type can enhance filling accuracy. Aim to fill the vial in a smooth and controlled manner to minimize the introduction of air bubbles into the solution. Air bubbles can affect the accuracy of the volume and potentially compromise the fill.

Furthermore, implementing quality control checks during the filling stages is vital for ensuring compliance with industry standards. Double-checking the volume and solution type before sealing the vial helps prevent costly mistakes and maintains regulatory compliance.

Post-filling procedures

After filling, it is crucial to seal the badd vial properly. Options for sealing include caps or shrink bands, which help create an airtight environment that protects the contents from contamination and evaporation. Ensure that the chosen method is applied efficiently to avoid leakage or any risk of exposure.

Labeling the filled vial accurately is also an important step. Labels should include essential details such as the content name, concentration, date of filling, and expiration if applicable. Accurate documentation not only ensures traceability but is also often a regulatory requirement.

Interactive tools for enhanced efficiency

Utilizing tools like pdfFiller can significantly streamline the process of managing documents related to badd vial uncapping and filling forms. pdfFiller allows users to create customized filling forms that can be accessed online, ensuring that your documents are standardized and consistent across the board.

Sharing templates with team members becomes effortless, and the collaboration features enable smooth approvals with eSignatures. This not only enhances efficiency but also ensures that all forms are compliant and stored securely.

Troubleshooting common issues

Encountering problems while handling badd vials is not uncommon. If the uncapping process goes awry, such as spills or damage to the vial, it’s essential to remain calm and take immediate corrective action. Dispose of any spillage according to your lab’s safety protocols and use a fresh vial if any contamination is suspected.

Filling errors like overfilling or underfilling can compromise results. Address these issues by checking measurements carefully during filing, and if an error occurs, empty the vial and refill appropriately. Regular training and familiarization with standard operating procedures can significantly minimize the occurrence of these issues.

Best practices for efficient badd vial management

Storage conditions for filled badd vials significantly affect the longevity and integrity of their contents. Ideally, filled vials should be stored in a controlled environment, free from extreme temperatures and direct sunlight. Properly labeling storage containers helps prevent mix-ups and ensures that all team members are aware of contents and expiration dates.

In addition to proper storage, regular maintenance and checks of inventory are crucial. Scheduling routine inspections ensures that vials remain in good condition and that any approaching expiration dates are monitored. Continuous improvement is facilitated by periodic evaluations of your processes, leading to more efficient techniques over time.

Additional information on compliance and safety

Adhering to regulatory standards for handling and filling badd vials is non-negotiable. Organizations must follow best practices as outlined by agencies such as the FDA and CDC to maintain compliance and ensure the safety of both personnel and public health. Continuous education for team members about these protocols enhances overall safety.

Establishing safety protocols for your team involves preparing detailed training sessions on the handling of vials, understanding risks, and emergency procedures. Access to well-documented processes can greatly reduce the potential for accidents and facilitate a safer workplace.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my badd vial uncapping filling directly from Gmail?

How can I get badd vial uncapping filling?

Can I sign the badd vial uncapping filling electronically in Chrome?

What is badd vial uncapping filling?

Who is required to file badd vial uncapping filling?

How to fill out badd vial uncapping filling?

What is the purpose of badd vial uncapping filling?

What information must be reported on badd vial uncapping filling?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.