Get the free polymer ball bearings - igus

Show details

...giros/... polymer ball bearings.lubrication-free.polymer ball bearings. LU ... ....EU/. Plastics.for.longer.life/...www.igus.eu/xiros/...tribo-polymer 1 /...giros/...tested.tested.tested/. Comparison-tests

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign polymer ball bearings

Edit your polymer ball bearings form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your polymer ball bearings form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing polymer ball bearings online

To use the services of a skilled PDF editor, follow these steps below:

1

Check your account. It's time to start your free trial.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit polymer ball bearings. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

With pdfFiller, it's always easy to work with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

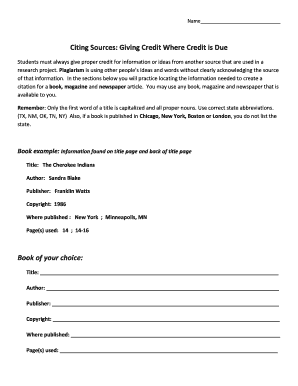

How to fill out polymer ball bearings

How to fill out polymer ball bearings:

01

Begin by obtaining the necessary equipment and materials for filling the polymer ball bearings. This may include a syringe or pipette for precision, a container of lubricant compatible with the polymer material, and the polymer ball bearings themselves.

02

Ensure that the workspace is clean and free from any contaminants that may adhere to the ball bearings. Dust, dirt, or other foreign particles can negatively affect the performance and lifespan of the bearings.

03

Gently handle the polymer ball bearings to prevent damage or scratching. These bearings are typically made from materials such as nylon or polypropylene, which can be durable but also susceptible to surface damage.

04

Using the syringe or pipette, carefully draw up the lubricant to be used for filling the ball bearings. The appropriate type and amount of lubricant may depend on the specific application and manufacturer's recommendations.

05

Position the syringe or pipette tip near the opening of the ball bearing. Slowly and steadily squeeze the lubricant into the bearing until it is adequately filled. Take care not to overfill, as this can cause excess lubricant to escape or hinder the bearing's functionality.

06

Once the ball bearing is filled, ensure that any excess lubricant is wiped off from the exterior. This will help maintain cleanliness and prevent unwanted lubricant from spreading to other components.

Who needs polymer ball bearings:

01

Industries that require smooth and efficient rotational motion often need polymer ball bearings. These bearings offer reduced friction, high wear resistance, and excellent corrosion resistance, making them suitable for various applications.

02

Automotive manufacturers and suppliers frequently utilize polymer ball bearings in applications such as electric power steering systems and fuel injection systems. These bearings can provide reliable performance and withstand harsh operating conditions.

03

Medical equipment manufacturers may use polymer ball bearings in devices such as surgical instruments, pumps, and dental tools. The low friction and biocompatibility of polymer materials make them well-suited for medical applications.

04

Packaging machinery, conveyor systems, and material handling equipment can benefit from the use of polymer ball bearings. The lightweight and self-lubricating properties of these bearings contribute to improved efficiency and reduced maintenance requirements.

05

Industries like food and beverage processing, where hygiene is crucial, often employ polymer ball bearings. These bearings can meet stringent cleanliness standards, resist chemicals, and prevent contamination of the product being processed.

In summary, filling out polymer ball bearings requires careful handling, the right lubricant, and precision. Various industries that value the advantages offered by polymer ball bearings rely on them for their specific applications.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is polymer ball bearings?

Polymer ball bearings are bearings made from polymer materials such as plastic or rubber, which offer advantages such as corrosion resistance and reduced friction.

Who is required to file polymer ball bearings?

Manufacturers or suppliers of polymer ball bearings may be required to file related documents for quality control and compliance purposes.

How to fill out polymer ball bearings?

Polymer ball bearings should be filled out with information such as material composition, dimensions, usage specifications, and compliance with industry standards.

What is the purpose of polymer ball bearings?

The purpose of polymer ball bearings is to provide a durable and lightweight alternative to traditional metal bearings for various mechanical applications.

What information must be reported on polymer ball bearings?

Information that must be reported on polymer ball bearings may include material certification, compliance with industry standards, dimensions, and usage specifications.

How can I edit polymer ball bearings from Google Drive?

Simplify your document workflows and create fillable forms right in Google Drive by integrating pdfFiller with Google Docs. The integration will allow you to create, modify, and eSign documents, including polymer ball bearings, without leaving Google Drive. Add pdfFiller’s functionalities to Google Drive and manage your paperwork more efficiently on any internet-connected device.

How can I edit polymer ball bearings on a smartphone?

The pdfFiller mobile applications for iOS and Android are the easiest way to edit documents on the go. You may get them from the Apple Store and Google Play. More info about the applications here. Install and log in to edit polymer ball bearings.

How do I complete polymer ball bearings on an iOS device?

In order to fill out documents on your iOS device, install the pdfFiller app. Create an account or log in to an existing one if you have a subscription to the service. Once the registration process is complete, upload your polymer ball bearings. You now can take advantage of pdfFiller's advanced functionalities: adding fillable fields and eSigning documents, and accessing them from any device, wherever you are.

Fill out your polymer ball bearings online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Polymer Ball Bearings is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.