Get the free Bredel 10-20 Operating Manual

Get, Create, Make and Sign bredel 10-20 operating manual

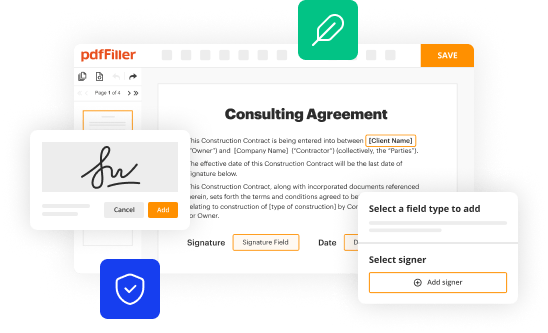

How to edit bredel 10-20 operating manual online

Uncompromising security for your PDF editing and eSignature needs

How to fill out bredel 10-20 operating manual

How to fill out bredel 10-20 operating manual

Who needs bredel 10-20 operating manual?

Comprehensive Guide to the Bredel 10-20 Operating Manual Form

Overview of Bredel 10-20 operating manual

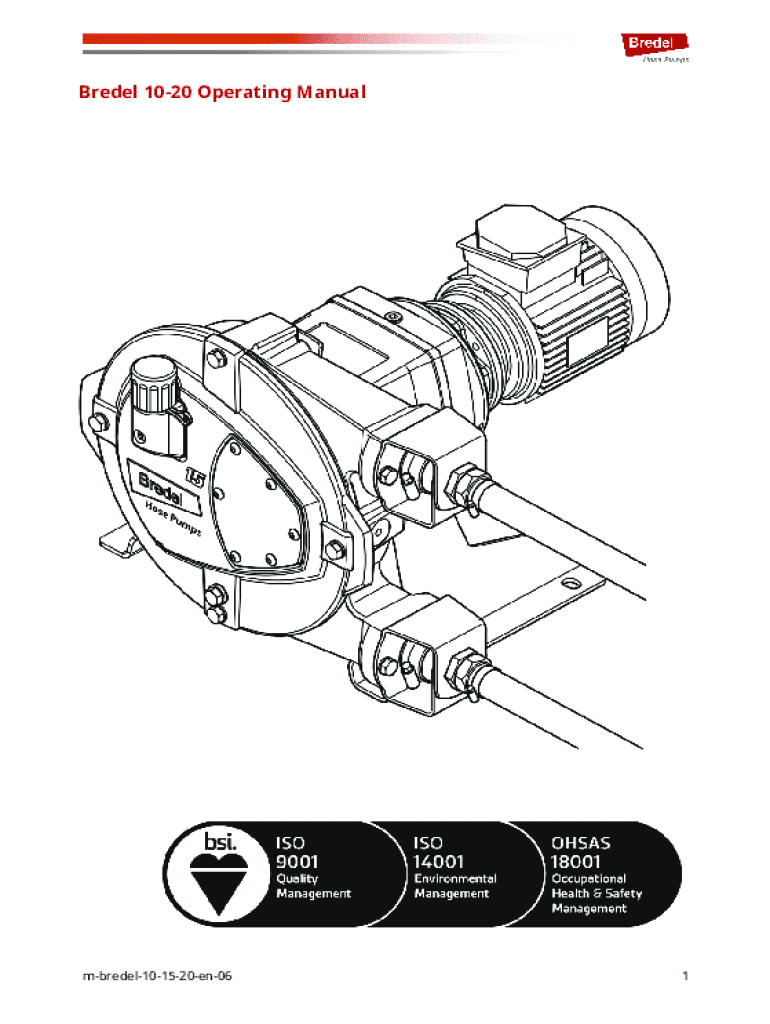

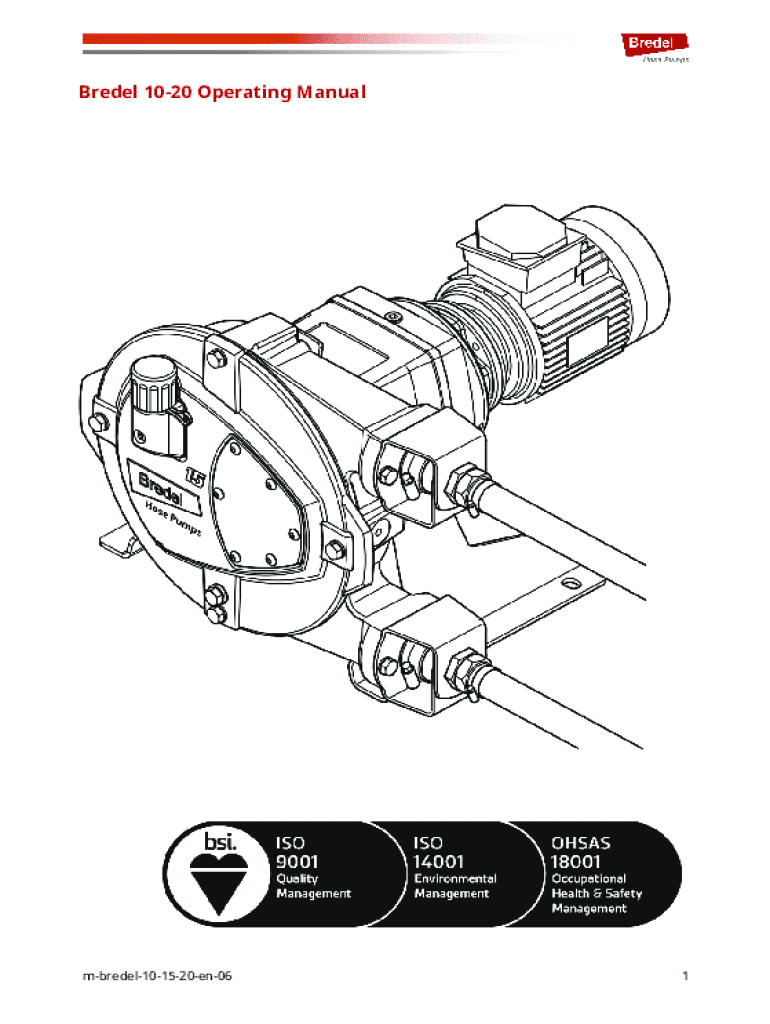

The Bredel 10-20 pump, a standout in industrial pumping solutions, is designed for handling thick slurries and viscous liquids. Its robust design ensures reliability and efficiency, making it a vital component across various industries such as pharmaceuticals, food and beverage, and wastewater management. Understanding its intricacies is essential for optimal operation and maintenance; thus, the Bredel 10-20 operating manual form serves as a critical resource for pump users. Following the manual precisely not only enhances performance but also significantly extends the lifespan of the pump.

The operating manual is neatly structured into sections that focus on safety, installation, maintenance, and troubleshooting, among other crucial aspects. Each section is designed to provide clear guidance for both novices and seasoned operators. By adhering to this manual, users can ensure compliance with operational standards and safety protocols.

Safety guidelines

Safety is paramount when operating the Bredel 10-20 pump. Before commencing any operation, users must familiarize themselves with essential safety precautions tailored for this equipment. These guidelines include conducting a thorough inspection of the pump and surrounding area, ensuring all components are secure and undamaged, and verifying the integrity of electrical connections.

Personal protective equipment (PPE) is mandatory for all personnel involved in the operation. Recommended PPE includes gloves, safety goggles, and ear protection, particularly in noisy environments. Additionally, emergency procedures documented in the manual should be readily accessible to all operators. These procedures encompass immediate steps to take in the event of equipment malfunction or spills.

Warranty information

The warranty for the Bredel 10-20 pump provides operators with peace of mind regarding their investment. The coverage typically includes defects in materials and workmanship for a specified period from the date of purchase. However, to maintain validity, users must ensure the pump is installed and maintained strictly as outlined in the operating manual.

To initiate a warranty claim, users should document any issues meticulously, including photos of defects and detailed descriptions. This information is crucial when contacting support agents, who will guide you through the claim process. Keeping a record of maintenance and use is also vital, as these logs may be requested to validate a warranty claim.

Bredel 10-20 pump description

The Bredel 10-20 pump is crafted with a robust design that enables it to handle a variety of challenging applications. Key specifications include a maximum flow rate of [insert specific flow rate], pressure ratings of [insert pressure ratings], and compatibility with various fluids, including abrasive and corrosive materials. Its construction often features high-grade materials that ensure durability and efficiency.

Each component of the pump is engineered for specific functionality, contributing to its overall performance. For instance, the pump's rotor is designed to facilitate smooth fluid movement, while the housing protects against environmental damage. Users should also note the variations within the Bredel series, as different models may offer capabilities suited to particular needs.

Installation process

Installing a Bredel 10-20 pump requires careful attention to detail to ensure optimal functioning. Before starting with the installation, operators should complete a pre-installation checklist that ensures all components are present and in good condition. Additionally, gathering the necessary tools such as wrenches, pliers, and screwdrivers beforehand can facilitate a smooth installation process.

The installation phase involves several critical steps: first, securely mounting the pump in a stable location to minimize vibration during operation. Then, connect pipes and hoses, ensuring that seals are tight to prevent leakage. Lastly, the electrical connections should be set up according to the specifications detailed in the operating manual, which includes proper wiring and connections to ensure safety and functionality.

Commissioning the pump

Once installed, the initial commissioning of the Bredel 10-20 pump is paramount to its long-term performance. This stage involves setting up the pump to ensure it operates efficiently and safely under normal conditions. Begin by running the pump at a low speed for a brief period to observe its startup characteristics and verify there are no leaks or unusual noises.

Calibration steps should follow, which may include adjusting the flow rate and pressure settings to match operational requirements. Operators must consistently monitor indicators that signal proper functioning, such as vibrations, temperature, and discharge pressure, to ensure optimal conditions.

Routine maintenance

Routine maintenance is crucial for the Bredel 10-20 pump to ensure continuous and efficient operation. The manual outlines a maintenance schedule, categorizing tasks into daily, weekly, and monthly intervals. Daily checks should include looking for leaks, verifying fluid levels, and ensuring all functions operate smoothly.

Weekly maintenance may encompass cleaning accessible components and lubricating moving parts to prevent wear and tear. Monthly tasks should involve more thorough inspections, potentially including substitute parts if any wear is detected. Keeping the pump clean and well-lubricated significantly reduces the risk of malfunctions.

Troubleshooting guide

The troubleshooting guide within the Bredel 10-20 operating manual provides essential insights into common issues that may arise during operation. Familiarizing yourself with this section can help save time and resources. For instance, if the pump is underperforming, first check the power supply and confirm that it’s properly connected.

Common issues include irregular flow rates, strange noises, or overheating. The manual offers diagnostic tips for identifying these problems, as well as solutions to rectify them. If troubleshooting does not resolve the issues, users are encouraged to seek professional assistance to prevent further damage.

Safe storage practices

Proper storage of the Bredel 10-20 pump is vital to preserving its longevity and functionality when not in use. Operators should follow guidelines specific to this pump to ensure it remains in optimal condition during extended periods of inactivity. The storage area should be dry and free of contaminants that could affect the pump's operation.

For long-term storage, it's advisable to drain any residual fluid and clean all components to prevent corrosion and build-up. Additionally, the pump should be covered or stored in a protective enclosure to shield it from dust and environmental changes that could compromise its effectiveness.

Operational guidelines

Adhering to operational guidelines is essential for optimal use of the Bredel 10-20 pump. The manual recommends specific operating conditions, including acceptable temperature ranges and fluid types, to prevent equipment strain or malfunction. Users should monitor for signs of overloading or malfunctioning, such as fluctuating pressure readings or unusually loud operation.

Employing best practices during operation can lead to improved pump performance. Regular monitoring of key indicators allows operators to adjust settings to maintain efficiency while avoiding potential issues. Moreover, optimizing the flow rate in accordance with manufacturer guidelines contributes significantly to maximizing the lifespan of the equipment.

Hazardous environments (ATEX compliance)

For applications in hazardous environments, compliance with the ATEX directives is non-negotiable when operating Bredel 10-20 pumps. Understanding and adhering to these requirements not only safeguards the operator but also minimizes the risk of equipment failure in explosive atmospheres. The manual specifies necessary features or modifications needed for safe operation in such settings.

Best practices for ensuring safety include conducting risk assessments prior to installation and maintaining clear communication regarding equipment safety among all operators. Additionally, routine training on ATEX compliance for all personnel involved in operation can significantly mitigate risks attached to working in explosive environments.

Customization and accessories

The Bredel 10-20 pump offers a range of customization options and accessories that can enhance its functionality in specific applications. Utilizing compatible parts not only optimizes performance but also maintains warranty coverage, as outlined in the operating manual. Some common accessories include specialized hoses, mounting brackets, and control panels tailored for additional functionalities.

Installing these accessories is often straightforward, typically requiring basic tools and adherence to the accompanying instructions. Ensuring proper compatibility with the pump is crucial to avoid any operational issues that may arise from improper fittings or equipment mismatches.

Parts list and assembly diagrams

A detailed parts list for the Bredel 10-20 pump can be invaluable when conducting repairs or upgrades. This list, included in the operating manual, outlines every component, along with part numbers for reference. Moreover, assembly diagrams provide a visual guide for users, making it easier to understand how each part fits together and functions.

For those needing to order replacement parts, the manual often explains how to utilize pdfFiller to streamline the order process. Users can fill out forms quickly to ensure they receive the correct parts without delay, keeping the pump operational and reducing downtime.

Environmental considerations

Environmental considerations are integral to responsible pump operation and maintenance. Users are encouraged to follow procedures for the disposal and recycling of old parts as specified in the operating manual. This approach ensures compliance with local regulations while also minimizing the environmental impact of worn-out components.

Furthermore, operators should be aware of the importance of environmentally sound practices during routine maintenance and repairs. This includes using recyclable materials whenever possible and managing waste responsibly throughout the equipment lifecycle.

Training resources

Comprehensive training resources for operators of the Bredel 10-20 pump are crucial for maximizing safety and efficiency. Recommended training programs can help users gain practical insights into the best practices for operation, maintenance, and troubleshooting. Training aids such as online tutorials and instructional videos may also be provided to facilitate learning.

pdfFiller offers various online support resources, assisting users in locating the essential information quickly. Should users have specific questions regarding the operating manual, they can find answers in the FAQs section that addresses common concerns and procedural inquiries.

Questions and answers section

A well-crafted Questions and Answers section helps users clarify common doubts regarding the Bredel 10-20 operating manual. Typical topics addressed in this section may cover installation procedures, troubleshooting steps, and maintenance tips. By browsing this section, operators can quickly find solutions to issues they might face, contributing to a more efficient use of the pump.

Encouraging engagement in this manner ensures that users remain informed and confident in their ability to handle various challenges associated with the pump’s operation and upkeep. This enhances overall operational efficiency and promotes a culture of safety and responsibility.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute bredel 10-20 operating manual online?

How can I fill out bredel 10-20 operating manual on an iOS device?

How do I complete bredel 10-20 operating manual on an Android device?

What is bredel 10-20 operating manual?

Who is required to file bredel 10-20 operating manual?

How to fill out bredel 10-20 operating manual?

What is the purpose of bredel 10-20 operating manual?

What information must be reported on bredel 10-20 operating manual?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.