Get the free Nylon Strain Relief Clamp PG Metric. Sealcon Strain Relief, Conduit and Accessories ...

Get, Create, Make and Sign nylon strain relief clamp

How to edit nylon strain relief clamp online

Uncompromising security for your PDF editing and eSignature needs

How to fill out nylon strain relief clamp

How to fill out nylon strain relief clamp

Who needs nylon strain relief clamp?

Comprehensive Guide to Nylon Strain Relief Clamp Form

Overview of nylon strain relief clamps

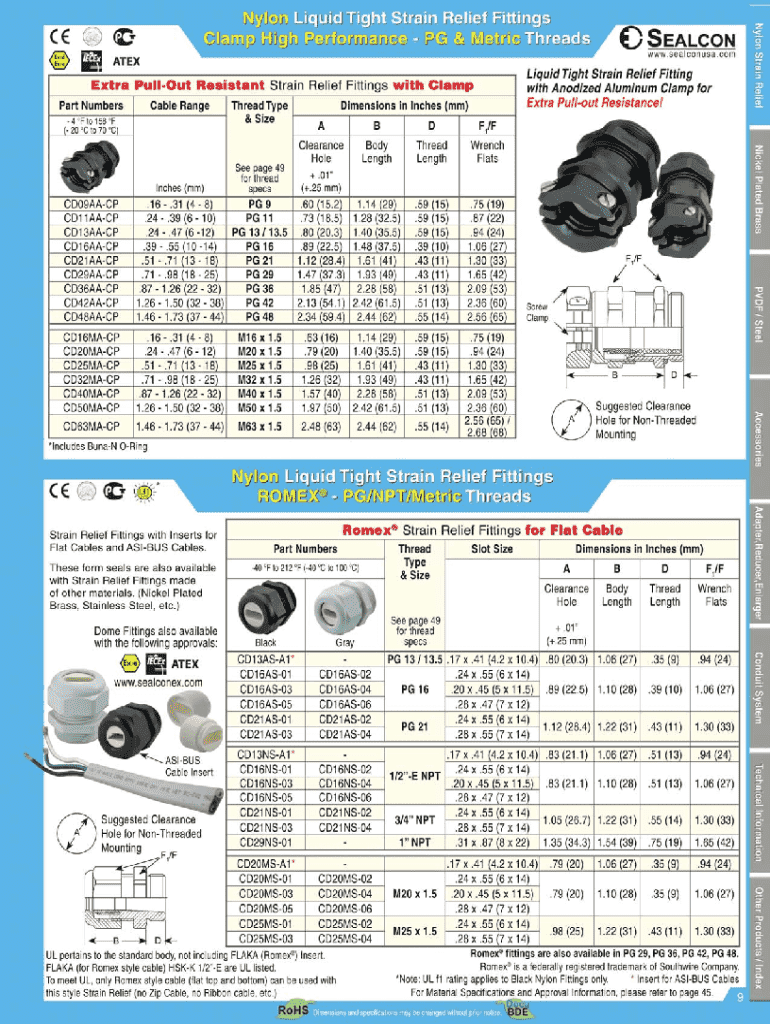

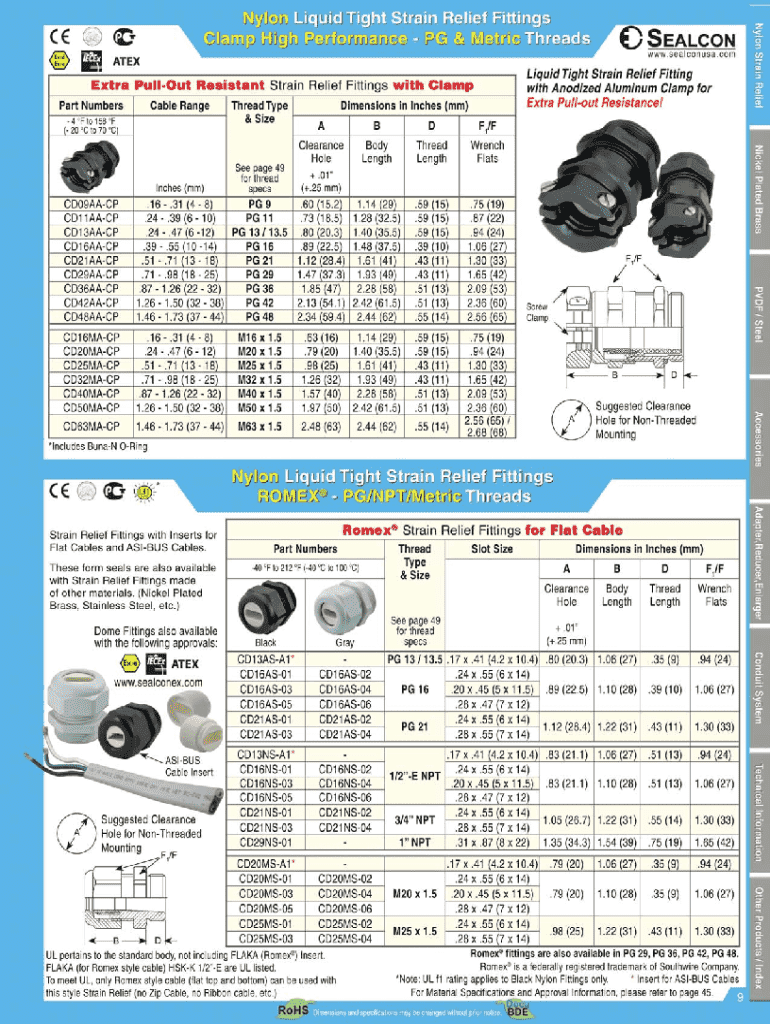

Nylon strain relief clamps serve a crucial function in the management and protection of cables, particularly in environments where they face potential hazards. These clamps are designed to reduce the stress placed on electrical cables, thereby safeguarding connections and enhancing longevity.

The primary purpose of nylon strain relief clamps is to provide support at the entry and exit points of cables, ensuring that pulling forces are properly managed. This is essential in both electrical and mechanical applications where safety is paramount. When stress is relieved, the risk of cable damage and electrical faults diminishes significantly.

The usage of nylon strain relief clamps can be observed across various industries, including automotive, manufacturing, and telecommunications. Each of these sectors relies on effective cable management to ensure workflow efficiency and safety.

Product features and benefits

When considering nylon strain relief clamps, it is essential to note key features that can significantly impact performance and durability. These clamps are widely appreciated for their robust construction, often made from high-quality nylon that ensures longevity and resistance to environmental factors.

Moreover, they are available in a variety of sizes, allowing for compatibility with numerous cable types and dimensions. This versatility is critical, particularly in environments where multiple cable sizes may be in use.

The benefits of using nylon strain relief clamps extend beyond protection. Users can enjoy improved safety, as these clamps actively contribute to minimizing risks associated with cable disconnection. Furthermore, their design facilitates easy installation and maintenance, making them a preferred choice for professionals in various fields.

Choosing the right nylon strain relief clamp

Selecting the appropriate nylon strain relief clamp is vital for successful implementation. Factors such as load capacity and compatibility with cable sizes must be carefully evaluated to ensure optimal performance. It’s beneficial to assess the specific use case to determine which clamp most effectively meets your requirements.

In addition to load capacity, considering the environmental conditions can influence your choice. For instance, outdoor applications may require clamps that offer enhanced UV resistance, whereas indoor setups might focus on electrical safety above all.

When comparing nylon clamps to other materials like rubber or metal, consider cost-effectiveness, installation ease, and resistance to environmental factors like moisture and chemicals. Nylon often emerges as a balanced option with a positive trade-off for durability and affordability.

Understanding the form structure

The nylon strain relief clamp form is essential for organizing your information efficiently. At its core, the form should capture key data such as the type of clamp being utilized, project specifications, and important environmental notes. Accurate completion of the form streamlines documentation processes and supports clear communication among team members.

The structure of the form includes essential fields, as well as optional sections that add clarity. Filling the form out accurately is crucial to achieving the best results. Common pitfalls include missing information or failing to specify cable sizes or environmental conditions.

To improve the accuracy of your submissions, consider employing best practices. Always double-check entries, clarifying any ambiguous terms. A well-filled form can accelerate project timelines and foster smoother collaboration among team members.

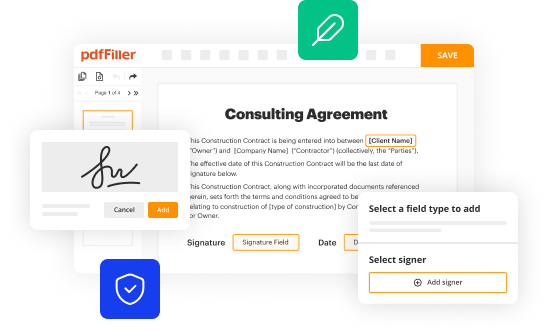

Interactive tools for document management

Utilizing pdfFiller’s features improves the ease of editing the nylon strain relief clamp form. The platform simplifies the process of adjusting fields, ensuring that all necessary information is clearly laid out. Users can take advantage of an intuitive interface to edit, add, or delete content directly within the document.

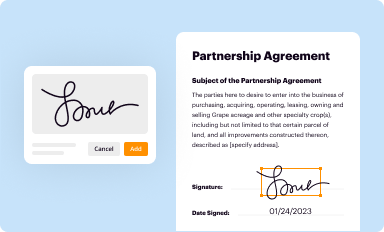

Additionally, the eSignature feature provides a secure method for individuals to sign documents digitally. This streamlines the approval process and eliminates delays associated with physical signatures.

Team collaboration is efficient with pdfFiller as well. Users can leave comments, suggest edits, and track changes, ensuring that all feedback is documented accurately. This transparency helps keep project stakeholders informed and engaged throughout the process.

Managing your documents and forms

An organized approach to document management aids in the efficient retrieval of your nylon strain relief clamp forms. Implementing categorization and tagging helps streamline your workflow, allowing for swift access to vital information when needed. This efficiency is particularly beneficial in environments where multiple documents are often accessed simultaneously.

Utilizing search functionalities within pdfFiller furthers this efficiency. By leveraging search terms relevant to your projects or documentation, retrieving specific forms becomes a matter of seconds rather than minutes.

Ensuring compliance and security within your documentation practices cannot be overstated. Familiarity with data protection regulations is vital for protecting sensitive project information. Implementing best practices for document security minimizes risks associated with unauthorized access and enhances overall project integrity.

Success stories and case studies

Examining case studies where nylon strain relief clamps have been effectively utilized provides insight into their practical applications. In one notable example, a telecommunications company integrated these clamps into their infrastructure project, significantly reducing cable-related incidents. Feedback from project managers highlighted improved safety and an overall decrease in maintenance costs.

Another instance involved an automotive manufacturer utilizing these clamps during assembly processes. By ensuring consistent cable management, they were able to streamline production and enhance safety standards across their facilities, showcasing how effective documentation practices, including the proper use of the nylon strain relief clamp form, greatly enhance project outcomes.

These real-world applications illustrate the impact that proper documentation and the strategic use of nylon strain relief clamps can have on a project’s success.

Frequently asked questions (FAQs)

Addressing common queries is crucial for both current and potential users of nylon strain relief clamps. For those encountering issues, troubleshooting is often straightforward. Regularly check for correct installations and ensure that clamps are not undersized for the cables in use. Miscalculations in load capacity can lead to premature failures.

If nylon strain relief clamps do not meet project needs, there are alternative solutions available. Rubber and metal clamps can also provide the required support, but careful consideration regarding cost and application should guide the decision. Each option carries its own set of advantages and drawbacks.

Additional products and accessories

Complementary accessories such as cable ties and conduits significantly enhance the performance of nylon strain relief clamps. These products work together, ensuring a cohesive cable management system that reduces strain and improves protection. By incorporating multiple accessories, you can create a framework that supports both organizational needs and safety requirements.

Furthermore, exploring further reading material can yield additional insights into efficient cable management practices and the effective use of strain relief clamps. Understanding the broader context of your components allows for better preparedness in project execution.

Community engagement and feedback

Encouraging users to share their experiences with nylon strain relief clamps fosters a community of knowledge and innovative practices. Collecting personal anecdotes and insights can lead to discovering new applications or best practices that enhance the overall effectiveness of these products.

Platforms dedicated to discussions around cable management solutions can serve as excellent resources for networking and learning from industry leaders. Such engagement not only improves individual experiences but can also contribute to the broader industry knowledge base.

Contact and support options

Should you need assistance with your nylon strain relief clamp form or any related queries, reaching out to pdfFiller support is straightforward. The platform provides multiple contact options to ensure that help is readily available for any document-related questions.

Additionally, submitting feedback on the form or platform enhancements can contribute to continuous improvement. Sharing experiences allows pdfFiller to better serve its users, refining the overall experience while ensuring that they have the tools necessary for effective documentation management.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify nylon strain relief clamp without leaving Google Drive?

How do I complete nylon strain relief clamp online?

How do I edit nylon strain relief clamp on an Android device?

What is nylon strain relief clamp?

Who is required to file nylon strain relief clamp?

How to fill out nylon strain relief clamp?

What is the purpose of nylon strain relief clamp?

What information must be reported on nylon strain relief clamp?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.