Get the free Wire & Cable Specification - Hbr.04.86.d

Get, Create, Make and Sign wire cable specification

How to edit wire cable specification online

Uncompromising security for your PDF editing and eSignature needs

How to fill out wire cable specification

How to fill out wire cable specification

Who needs wire cable specification?

Understanding the Wire Cable Specification Form

Understanding wire cable specifications

Wire cable specifications are critical documents that define the exact requirements needed for cable installation and application. These specifications outline the necessary characteristics and performance standards that cables must meet to ensure safety and efficiency in electrical projects. Accurate specifications are necessary to prevent costly errors, ensure compliance with safety standards, and facilitate clear communication among project stakeholders.

In various industries such as construction, telecommunications, and manufacturing, precise specifications allow teams to choose the right cable type and gauge for specific applications. For example, when installing electrical systems in residential buildings, specifications determine the suitable wire type, gauge, and insulation material needed, ensuring that the installation is safe and functional.

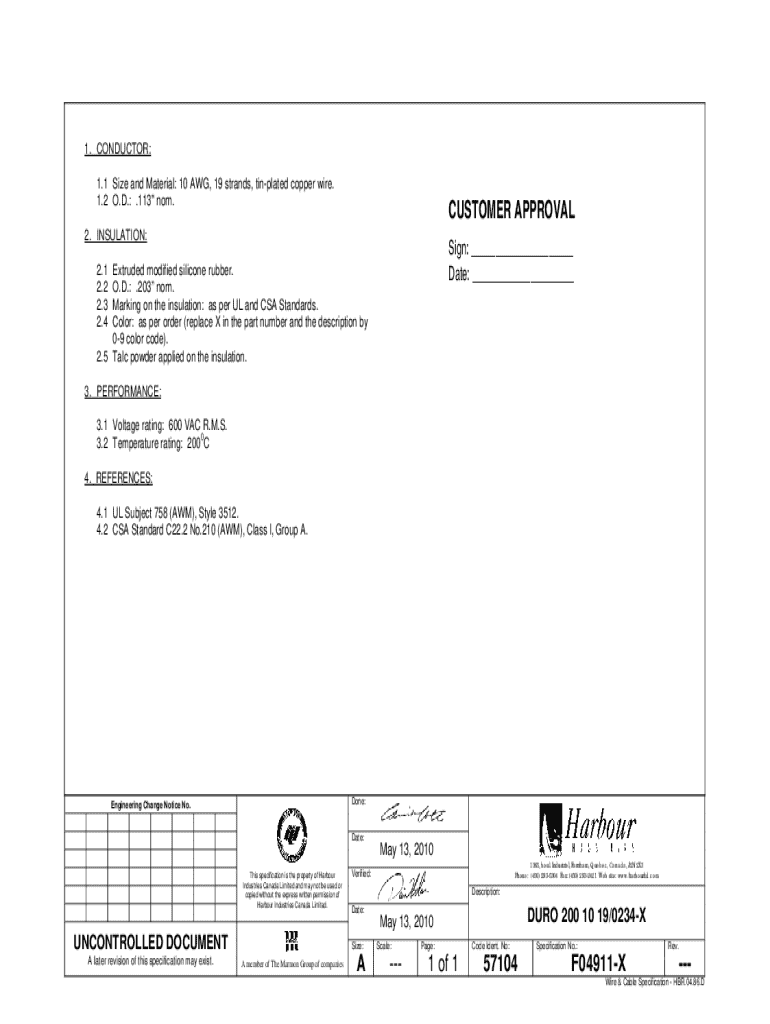

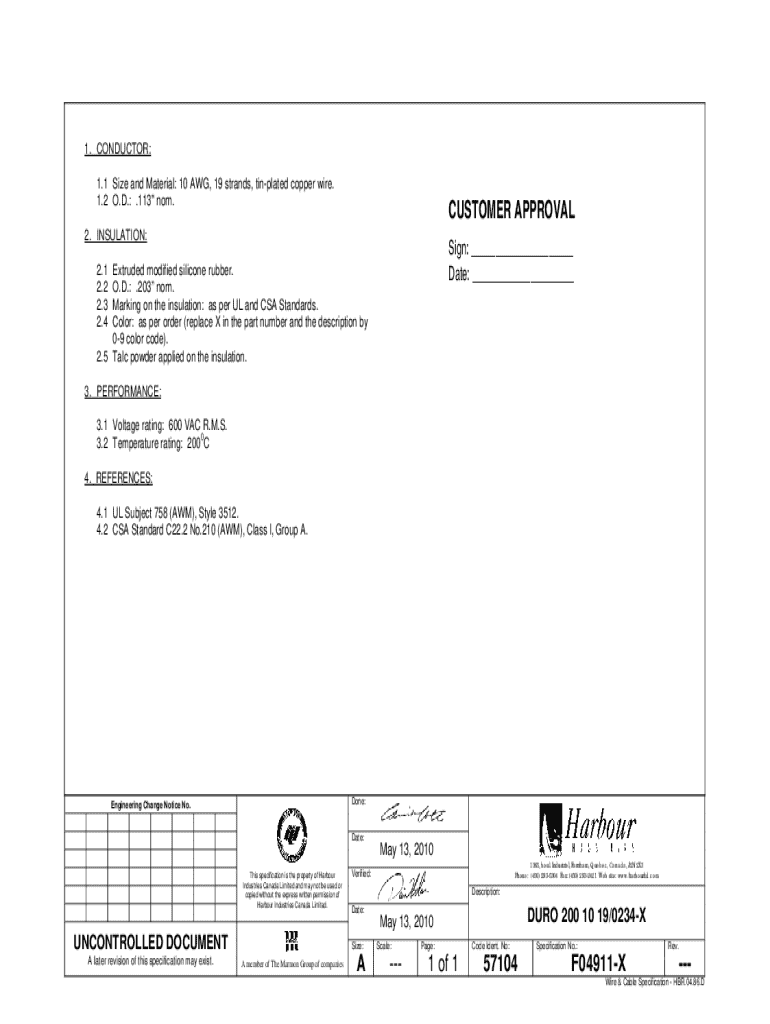

Key components of a wire cable specification form

When creating a wire cable specification form, several key components must be included to ensure comprehensiveness. The first component involves delineating the cable types and variations. Different cables serve different purposes; thus, it is paramount to select the appropriate type. Commonly used wire cable models include twisted pairs, coaxial cables, and fiber optic cables. Each type has unique electrical and physical characteristics tailored to specific applications.

Electrical requirements on the specification form must cover voltage ratings and current-carrying capacity. Voltage ratings typically refer to the maximum voltage a cable can handle safely without risk of failure. Similarly, understanding the current-carrying capacity is vital; it indicates how much electricity can flow through the wire without overheating.

Physical requirements involve specifying cable sizes, such as gauge or diameter, and material specifications, particularly the choice between copper and aluminum conductors. Each material offers different advantages; copper has better conductivity but may be costlier, while aluminum is lighter and resistant to corrosion.

Environmental considerations are crucial in the specification process. This includes temperature ratings, moisture and chemical resistance, and UV protection. Each of these factors plays a significant role in determining when and where certain types of cables can be effectively utilized.

The cable specification process

The first step in the cable specification process involves determining project needs. Assessing load requirements is critical for understanding how much electrical load the cable will need to carry, which directly influences the choice of cable type, size, and material used.

Next is understanding environmental factors. This includes identifying the conditions under which the cable will operate; for instance, will it be used in a moist environment or exposed to high temperatures? The answers to these questions will impact the specifications significantly.

Filling out the specification form should be done meticulously. A step-by-step guide to completing each section can significantly aid in avoiding common mistakes. When detailing electrical ratings, it's essential to ensure they align with the operational requirements. Also, overlooking environmental risks can lead to equipment failure, so this should always be a primary consideration.

Common standards & regulations

Wire cable specifications must comply with established international standards that ensure safety and effectiveness. Organizations such as the British Standards (BS) and International Electrotechnical Commission (IEC) lay down guidelines that cables must meet. These standards help maintain consistency and reliability in cable performance across different regions of the world.

Labeling and compliance requirements are also integral to the specification process. Proper labels must detail key information about the cable's capabilities, including its ratings and usage instructions. Not adhering to compliance can lead to significant liabilities, as non-compliant cables may fail to perform under specified conditions, which could result in accidents.

Furthermore, safety standards govern the construction and installation of wire cables. Regulatory authorities like the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) play an exemplary role in setting these standards and ensuring that manufacturers adhere to them.

Advanced considerations in cable specification

In some instances, projects may necessitate custom cable specifications. Knowing when to use customized specs can help engineers and architects save time and resources while precisely meeting specific requirements. A checklist for creating customized specifications should guide professionals in addressing unique needs or harsh operating conditions.

As technology evolves, innovations in cable technology continue to affect specification practices. New materials and insulation types offer enhanced performance and durability, telling industry players to stay informed about the latest developments in cable design and usage. Future trends may see cables that are lighter, more efficient, and better suited to emerging technologies such as electric vehicles and renewable energy systems.

Interactive tools for cable specification

Using digital tools can significantly streamline the process of filling out wire cable specification forms. Platforms like pdfFiller provide various calculators and templates that assist users in accurately completing their specifications. A voltage drop calculator, for example, can help estimate how much voltage loss occurs over a certain distance, ensuring that the cable will operate efficiently under load.

Additionally, various load capacity assessment tools can further aid in determining the correct cable specifications according to the intended application. Utilizing templates not only saves time but also ensures that all necessary sections are completed correctly, reducing the risk of errors and omissions.

Managing and verifying your cable specifications

Effective document management is essential when working with cable specifications. Best practices for digital storage and retrieval include organizing documents in designated folders and using reliable naming conventions that make locating files easy. This organizational structure helps minimize the time spent searching for specific documents during critical project phases.

Collaboration among team members is also enhanced through structured feedback processes. Utilizing cloud-based platforms like pdfFiller allows multiple stakeholders to review, edit, and provide feedback conveniently, fostering seamless collaboration. Moreover, tracking revision history becomes vital; maintaining records of changes ensures that all modifications are transparent and that teams can revert to previous versions if necessary.

Frequently asked questions (FAQ)

Understanding wire cable specifications can often lead to questions among users seeking clarity. One common question is the difference between copper and aluminum cables; copper generally provides better conductivity and strength, while aluminum is lighter and less expensive. Choosing one over the other depends on the specific application and budget.

Another query often revolves around identifying the best insulation type for various applications. The type of insulation required is directly linked to environmental conditions like exposure to moisture, temperature, and potential chemical exposure. Non-compliance with cable specifications can lead to equipment failures, raising safety concerns and financial liabilities. If changes are needed after submission, many platforms allow users to edit their specifications to correct or update information.

Additional insights on wire cables

One popular misconception is that all wire cables are the same; however, various types exist to serve specific functions based on molecular properties and insulation. Understanding these differences is vital for effective project execution and safety.

Additionally, expert opinions indicate that industry trends are shifting towards more durable and efficient cable solutions, influenced by advancements in technology and the growing demand for sustainability. Case studies show that projects employing accurate specifications contribute to superior performance and lower long-term costs.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send wire cable specification for eSignature?

How do I execute wire cable specification online?

How do I edit wire cable specification on an iOS device?

What is wire cable specification?

Who is required to file wire cable specification?

How to fill out wire cable specification?

What is the purpose of wire cable specification?

What information must be reported on wire cable specification?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.