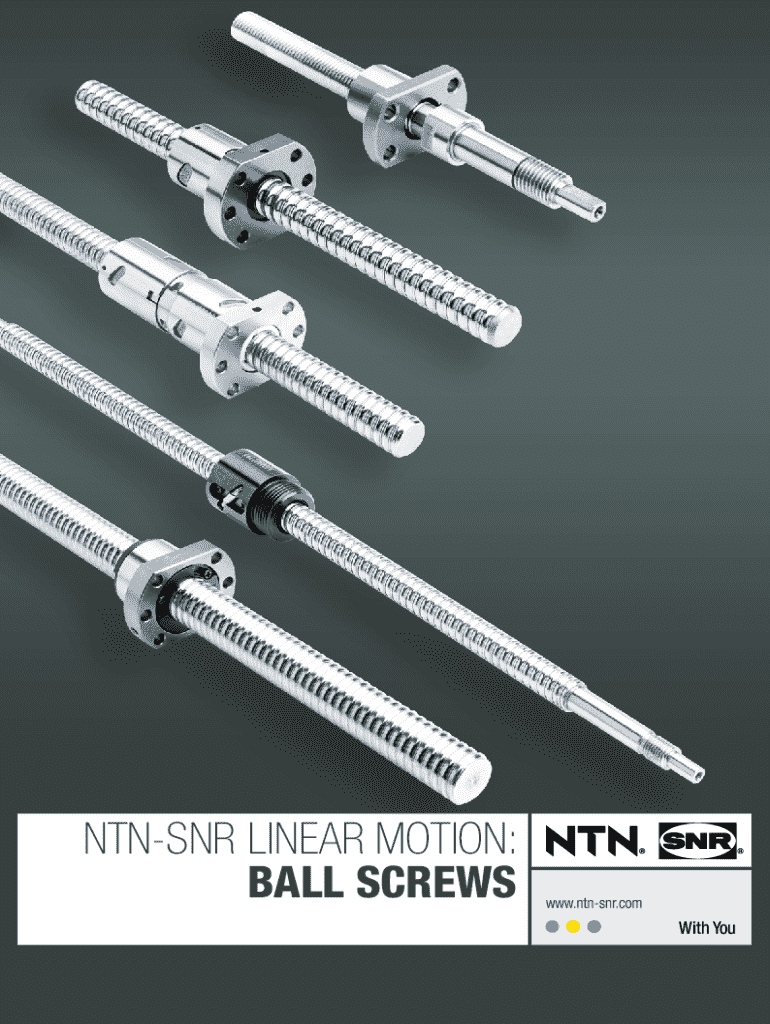

Get the free Ntn-snr Linear Motion: Ball Screws

Get, Create, Make and Sign ntn-snr linear motion ball

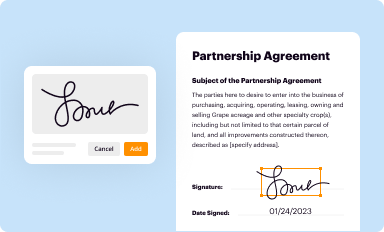

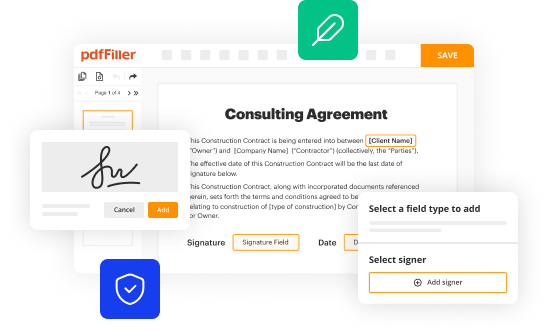

Editing ntn-snr linear motion ball online

Uncompromising security for your PDF editing and eSignature needs

How to fill out ntn-snr linear motion ball

How to fill out ntn-snr linear motion ball

Who needs ntn-snr linear motion ball?

NTN-SNR Linear Motion Ball Form: Comprehensive Guide

Overview of NTN-SNR linear motion technology

Linear motion systems are essential in various applications requiring precise movement along a straight path. This technology is crucial in scenarios ranging from assembly lines to complex robotic systems, providing accuracy and reliability. NTN-SNR has established itself as a leader in the linear motion sector, offering a wide range of products designed to meet the diverse needs of different industries.

The role of NTN-SNR in linear motion solutions spans multiple sectors, including automotive, aerospace, and manufacturing. Their linear motion products incorporate innovative designs and robust materials to ensure long-lasting performance.

In industries like robotics, where speed and precision are paramount, NTN-SNR linear motion solutions enable manufacturers to optimize processes and reduce downtime, directly impacting productivity.

Detailed exploration of linear motion ball forms

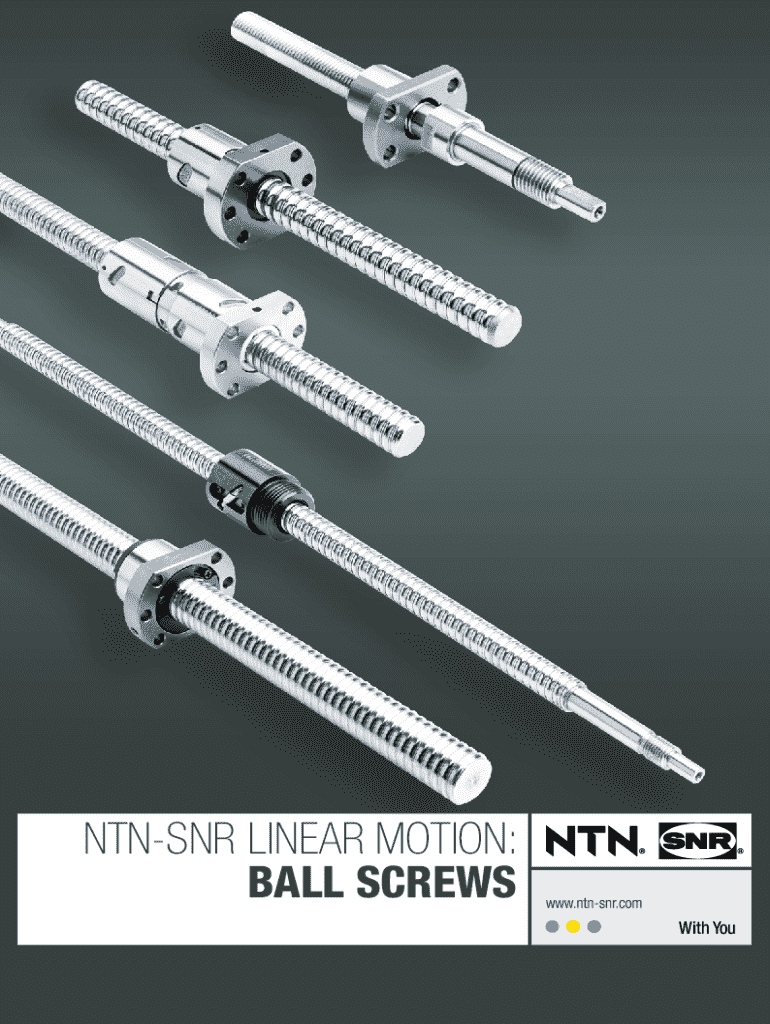

Linear motion ball forms are integral components in linear guides and rail systems. They facilitate smooth and accurate movement by utilizing ball bearings that roll between specially designed raceways, minimizing friction. NTN-SNR specializes in producing these ball forms, which come in various sizes and materials based on specific application requirements.

The manufacturing process of NTN-SNR linear motion ball forms involves precision engineering techniques. Each ball is crafted to exact specifications using high-grade materials that offer both strength and lightweight properties. Ensuring the perfect sphere and smooth surface finish is essential to reduce wear and enhance performance.

The benefits of using NTN-SNR linear motion ball forms include enhanced load capacity, reduced friction, and the ability to withstand extreme operating conditions, making them ideal for a broad spectrum of applications.

Essential components of linear motion systems

A linear motion system comprises several critical components, with linear guides being among the most fundamental. Linear guides, including roller and ball types, are designed to provide stable and accurate linear movement in machinery. For instance, ball guides allow for smoother motion, while roller guides provide greater load capacities.

Linear bushings and shafting complement these systems by providing self-aligning options that accommodate misalignment and reduce wear. Additionally, ball screws are essential for converting rotary motion into linear movement, providing high precision, while commercial actuators enhance the functionality and efficiency of these systems.

Innovative tools for linear motion projects

The complexity of linear motion projects necessitates the use of innovative tools that streamline design and implementation. NTN-SNR offers interactive 3D linear modeling tools, allowing engineers to visualize their system designs easily. These models facilitate better understanding and dimensional accuracy, critical for ensuring compatibility with existing setups.

Another significant tool is the linear guide configurator, which assists users in selecting the correct components tailored to their specific needs. This configurator considers load requirements, space constraints, and desired movement characteristics, simplifying the decision-making process.

Implementing NTN-SNR solutions in your projects

Selecting the right NTN-SNR products for your linear motion project is vital for achieving optimal performance. A step-by-step guide includes identifying project requirements, such as load capacity, operational speed, and environmental conditions. Understanding these requirements helps in making informed decisions regarding the choice of ball forms, guides, and other components.

Evaluating compatibility with existing systems is crucial to prevent costly modifications or inefficiencies in operation. Comparing product features, materials, and benefits allows for a comprehensive understanding of which solutions best meet your needs.

Effective installation strategies, coupled with maintenance tips and troubleshooting guidelines, ensure longevity and optimal operation of your NTN-SNR solutions.

Applications in diverse industrial sectors

NTN-SNR linear motion ball forms find applications in a multitude of industries. In the automotive industry, they are used in assembly lines for components where precise linear movement is required to enhance productivity and accuracy. Robotics and automation also heavily rely on these components, as they enable sophisticated motion control necessary for complex robotic tasks.

In manufacturing and assembly lines, efficient movement mechanisms are fundamental, and NTN-SNR linear solutions deliver the needed reliability and performance. Aerospace and defense industries demand high-performance components that withstand extreme conditions, and NTN-SNR products are engineered to meet these rigorous demands.

Customer support and resources

Accessing reliable product documentation and user guides is crucial for maximizing the utility of NTN-SNR linear motion products. Comprehensive manuals provide insights into specifications, installation guidance, and troubleshooting steps to overcome common issues. NTN-SNR emphasizes customer support by offering training services to users, allowing seamless onboarding onto their systems.

Online tools further enhance the user experience by allowing customers to perform tasks like comparing product specifications or accessing training resources easily. These tools are designed to support users in every phase of project implementation, from initial planning to ongoing maintenance.

Ensuring quality, safety, and cost reduction

Quality assurance is a cornerstone of NTN-SNR's production strategy. Each component undergoes rigorous testing and quality checks to meet international safety standards, ensuring reliability in all applications. Safety compliance is paramount, particularly in industries like aerospace and automotive, where failures can result in catastrophic consequences.

Furthermore, the cost-effectiveness of NTN-SNR products is evident in their durability and performance. Investing in high-quality linear motion solutions translates into fewer replacements and reduced maintenance costs over time, enabling businesses to allocate resources more efficiently.

Future trends in linear motion technology

As industries evolve, so do the technologies surrounding linear motion systems. Innovations such as automation and smart technologies are paving the way for even greater efficiencies. Manufacturers are integrating IoT capabilities into linear systems, enabling real-time monitoring and predictive maintenance, which can significantly reduce downtime and enhance operational efficiency.

Moreover, sustainability is becoming a key consideration in the design of linear motion products. Manufacturers are increasingly focusing on reducing environmental impacts through innovative designs and materials. NTN-SNR is committed to exploring these potential advances, ensuring that their products align with future industry standards.

Key takeaways and next steps

In conclusion, NTN-SNR linear motion ball forms are essential components that enhance efficiency and precision across various industries. Their dedication to quality, innovation, and customer support positions them as a key player in the linear motion market.

For teams seeking to implement NTN-SNR solutions, it is crucial to thoroughly understand project requirements and utilize the comprehensive resources available for product selection and installation. The investment in high-quality components not only assures operational efficiency but also supports long-term success.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

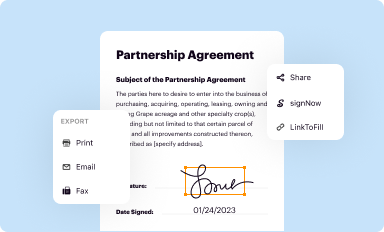

Can I create an electronic signature for the ntn-snr linear motion ball in Chrome?

Can I create an eSignature for the ntn-snr linear motion ball in Gmail?

How do I fill out ntn-snr linear motion ball on an Android device?

What is ntn-snr linear motion ball?

Who is required to file ntn-snr linear motion ball?

How to fill out ntn-snr linear motion ball?

What is the purpose of ntn-snr linear motion ball?

What information must be reported on ntn-snr linear motion ball?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.