Get the free continuous level sensor type NSL, level detector with integrated temperature sensor

Get, Create, Make and Sign continuous level sensor type

How to edit continuous level sensor type online

How to fill out continuous level sensor type

How to fill out continuous level sensor type

Who needs continuous level sensor type?

Comprehensive Guide to Continuous Level Sensor Type Form

Overview of continuous level sensors

Continuous level sensors play a pivotal role in industrial automation by providing real-time measurement of liquid or solid levels within containers or tanks. Unlike point level sensors, which provide a single measurement, continuous level sensors offer a dynamic view of the level that can be crucial for effective resource management and avoiding overflow or underflow conditions. Accurate level measurement is particularly significant in industries where maintaining specific levels of materials is critical, such as in chemical processing, food and beverage, and wastewater treatment.

Understanding continuous level sensor types

Continuous level sensors come in various types, each designed to meet specific operational requirements. Four of the most common types include ultrasonic, magnetostrictive, capacitive, and radar level sensors. Understanding the distinguishing features of each type can aid in selecting the most suitable sensor for a given application.

Applications of continuous level sensors

Continuous level sensors are employed across diverse industries, each utilizing their unique capabilities to improve operational efficiency and safety. Common applications include monitoring water levels in treatment facilities, maintaining adequate levels in food processing tanks, and ensuring safety in chemical manufacturing. Each sector tailors the use of sensors to their specific needs, showcasing the versatility of these devices.

Custom options for continuous level sensors

The adaptability of continuous level sensors is one of their standout features. Manufacturers often provide customizable options that allow users to tailor sensors according to the specific requirements of their applications. Whether it’s adjusting the range, sensitivity, or communication protocols, these custom solutions can significantly enhance operational outcomes. Configurator tools are commonly available, enabling users to specify and customize sensors directly online.

Benefits of implementing continuous level sensors

Implementing continuous level sensors offers numerous advantages, notably enhancing accuracy and reliability in measurement. These sensors help reduce operational downtimes by providing early warning signs of potential failures. Their design often includes no moving parts, leading to lower maintenance costs and increased lifespan. Furthermore, advanced smart technologies integrated into these sensors, such as IO-Link, enable better monitoring and data collection, adding another layer of efficiency to their use.

Selection criteria for continuous level sensors

When selecting a continuous level sensor, it is crucial to consider various factors to ensure optimal performance. The operating environment significantly affects the choice; harsh conditions may require more robust sensor designs. Additionally, the type of medium being measured (liquid, solid, or gas) influences the sensor type chosen. Understanding the required range and calibration needs is also vital to selecting a sensor that will deliver reliable data.

Installation and maintenance of continuous level sensors

Proper installation and regular maintenance of continuous level sensors are essential to ensure optimal performance and longevity. Best practices suggest following manufacturer guidelines closely during installation to avoid common pitfalls such as incorrect positioning or environmental interference. Ongoing maintenance should focus on calibration checks and visual inspections, especially in environments where build-up or fouling may occur. Knowing how to troubleshoot common issues can also save time and maintain uninterrupted operations.

Innovative features of continuous level sensors

Continuous level sensors have evolved, incorporating innovative features that enhance their functionality. Non-contact sensing technologies, for instance, have seen advancements that allow for measurements without direct contact with materials, reducing the risk of contamination. Moreover, many modern devices are equipped with advanced detection technologies that improve measurement precision. Alarm systems and fail-safe measures play a crucial role, as they provide immediate notifications of any potential failures, ensuring systems remain safe and efficient.

Comparative analysis: continuous level sensors vs. other measurement devices

When comparing continuous level sensors with other measurement devices such as pressure sensors and float sensors, significant differences emerge in terms of efficiency and adaptability. Continuous level sensors are particularly suited for applications requiring ongoing data, while pressure sensors may only give indirect level readings. Choosing the right technology ultimately depends on the application, environmental conditions, and the specific needs of the facility.

Frequently asked questions about continuous level sensors

Users often have essential queries that can help them make informed decisions. For instance, many ask about the best continuous level sensor for high-temperature applications or how these sensors manage in environments with strong vibrations. Understanding the maintenance requirements and the compatibility of the sensors with various aggressive chemicals also tops the list of frequently asked questions.

Interactive tools for continuous level sensor selection

Online configurators and interactive tools provided by manufacturers make the process of selecting continuous level sensors more accessible. These tools guide users through the selection process step-by-step, allowing customization based on operational requirements. Tutorials and guides further enhance user understanding, ensuring they can effectively choose the right sensor to meet their needs.

Customer testimonials and success stories

Real-world examples of continuous level sensor implementations highlight their impact on operational efficiency. Testimonials from users demonstrate how adopting these sensors has led to enhanced accuracy, less downtime, and better compliance with regulations. These success stories serve as powerful endorsements of the reliability and functionality of continuous level sensors across various industries.

Contact information for further assistance

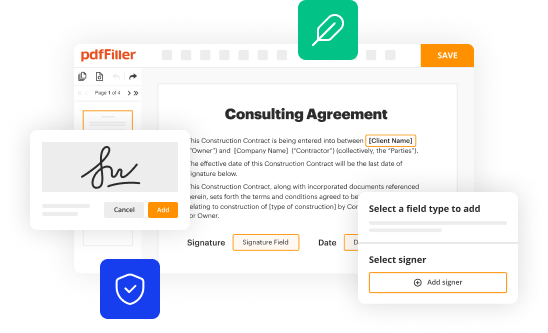

For those seeking further assistance with continuous level sensor type forms, support channels are readily available. Users can reach out to pdfFiller for inquiries about customization options, troubleshooting, or general information. With availability around the clock, assistance is just a message away, ensuring that users can receive the help they need when they need it.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify continuous level sensor type without leaving Google Drive?

How can I send continuous level sensor type to be eSigned by others?

How do I complete continuous level sensor type on an Android device?

What is continuous level sensor type?

Who is required to file continuous level sensor type?

How to fill out continuous level sensor type?

What is the purpose of continuous level sensor type?

What information must be reported on continuous level sensor type?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.