Get the free EHEDG-Approval for Tubular Heat Exchanger

Get, Create, Make and Sign ehedg-approval for tubular heat

How to edit ehedg-approval for tubular heat online

Uncompromising security for your PDF editing and eSignature needs

How to fill out ehedg-approval for tubular heat

How to fill out ehedg-approval for tubular heat

Who needs ehedg-approval for tubular heat?

EHEDG approval for tubular heat form: A comprehensive guide

Understanding EHEDG approval

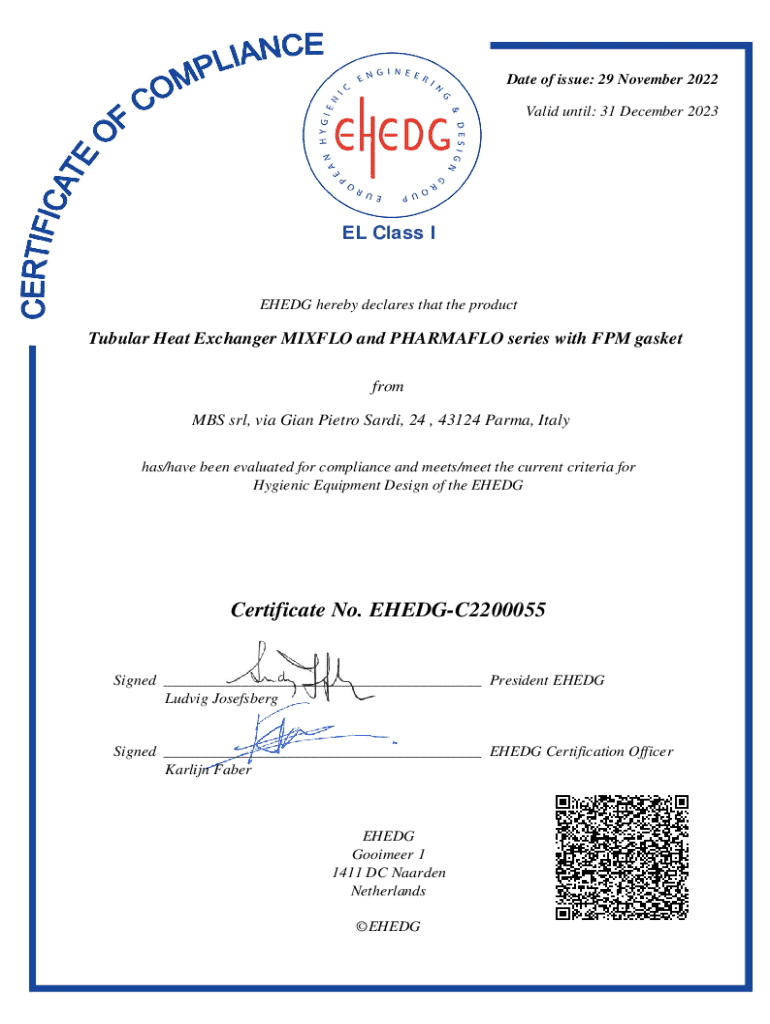

EHEDG, or the European Hygienic Engineering and Design Group, provides a framework for the hygienic design of equipment used in food manufacturing. EHEDG approval is critical for ensuring that equipment meets stringent hygiene standards throughout its lifecycle, particularly in the food and beverage industry. This approval helps manufacturers mitigate risks associated with equipment contamination and supports compliance with regulatory requirements.

What is a tubular heat exchanger?

A tubular heat exchanger is a type of heat transfer device that uses a series of tubes to transfer heat between fluids. This design typically consists of an outer shell and a set of tubes through which one fluid flows, with the other fluid flowing around these tubes. The main advantage of tubular heat exchangers is their efficiency in heat transfer, which is critical in maintaining the quality and safety of food and beverage products.

Common applications of tubular heat exchangers include pasteurization, sterilization, and thermal processing in the food and beverage industry. Their easy maintenance and cleaning capabilities make them particularly suitable for industries such as dairy and beverage manufacturing, where hygiene is paramount.

The process of achieving EHEDG approval

Achieving EHEDG approval involves a series of well-defined steps aimed at demonstrating compliance with the strict hygiene standards it embodies. This process ensures that your tubular heat exchanger meets the expectations for safety and effectiveness in food processing.

Essential standards for EHEDG approval

The guidelines established by EHEDG focus on both hygiene and design principles necessary for food processing equipment. The standards are designed to facilitate safety and minimize the risk of contamination during manufacturing processes. Compliance with these standards is required for EHEDG certification.

Customizing tubular heat exchangers for EHEDG compliance

To ensure that tubular heat exchangers meet EHEDG standards, customization of materials and design principles is crucial. Selecting the right materials involves using non-corrosive stainless steel or other food-grade materials that resist contamination. Additionally, incorporating sanitary design principles can help create an efficient and hygienically safe piece of equipment.

Addressing common design challenges, such as liquid retention in crevices or using components that are difficult to clean, can also significantly enhance compliance. A good design will ensure that all parts of the exchanger can be reached for cleaning without disassembly.

Case studies: Successful EHEDG approvals

Several companies have successfully obtained EHEDG certification for their tubular heat exchangers, showcasing the value and compliance of their technology. For instance, a leading dairy processor redesigned their tubular heat exchanger to meet EHEDG standards, resulting in improved safety metrics and reduced downtime due to cleaning.

In the beverage industry, another case study highlighted a tubular heat exchanger designed for juice processing. The innovative design not only secured EHEDG approval but also increased the efficiency of the pasteurization process, positively impacting overall production costs.

Interactive tools for document management and EHEDG approval

Utilizing effective document management solutions such as those offered by pdfFiller can streamline the EHEDG approval process. Interactive tools aid in creating, editing, and managing compliance documents easily while keeping track of updates and revisions. This is particularly useful during the rigorous documentation stage of the certification process.

Managing document workflows for EHEDG certification

Navigating the certification process can be complex, but tools from pdfFiller can help simplify workflows significantly. Document management features allow teams to collaborate more effectively, ensuring that everyone involved in the certification process has access to the most up-to-date information and can contribute to compliance documentation.

Expert insights on EHEDG trends and compliance best practices

Keeping informed about the latest trends in food safety and equipment hygiene is vital for companies looking to maintain EHEDG compliance. Experts recommend staying abreast of evolving standards and best practices that impact not just the design of heat exchangers but all food processing equipment.

Exploring advanced sealing solutions for tubular heat exchangers

Effective sealing solutions are paramount in maintaining the integrity and compliance of tubular heat exchangers. The right sealing technologies can prevent leaks and contamination, which are critical for meeting EHEDG standards. Understanding different sealing options allows manufacturers to choose the most suitable solutions for their applications.

Innovative technologies, such as welded and adhesive bonding seals, are gaining traction for their durability and reliability. These advanced sealing methods not only contribute to compliance but also enhance the overall performance of heat exchangers.

Troubleshooting common issues during the certification process

Seeking EHEDG approval can reveal various challenges, from documentation inconsistencies to design flaws. Identifying these issues early can save time and ensure compliance. Common pitfalls include not adhering to documentation specifics required for the application and overlooking design aspects that impede the cleaning process.

A proactive approach by conducting thorough reviews of design and documentation can facilitate a smoother certification process. Engaging experts for second opinions can also prevent costly mistakes.

Next steps after achieving EHEDG approval

Achieving EHEDG approval is just the beginning; maintaining compliance is essential to ensure ongoing product safety and reliability. Regular re-evaluations are important to adapt to any changes in standards or operational practices. Upgrading machinery and processes as necessary can prevent obsolescence and maintain market competitiveness.

Leveraging the benefits of EHEDG approval includes promoting your compliant equipment in marketing efforts, showcasing commitment to safety, and attracting a more quality-conscious customer base.

Stay informed: Subscribe for updates

Staying updated on EHEDG standards is crucial for any manufacturer involved in food processing. Subscribing to relevant newsletters, joining industry associations, and regularly checking the EHEDG website can help professionals keep pace with the latest developments and best practices in equipment safety.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send ehedg-approval for tubular heat to be eSigned by others?

How do I edit ehedg-approval for tubular heat on an iOS device?

Can I edit ehedg-approval for tubular heat on an Android device?

What is ehedg-approval for tubular heat?

Who is required to file ehedg-approval for tubular heat?

How to fill out ehedg-approval for tubular heat?

What is the purpose of ehedg-approval for tubular heat?

What information must be reported on ehedg-approval for tubular heat?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.